Page 10

Cleaning&Sanitizing

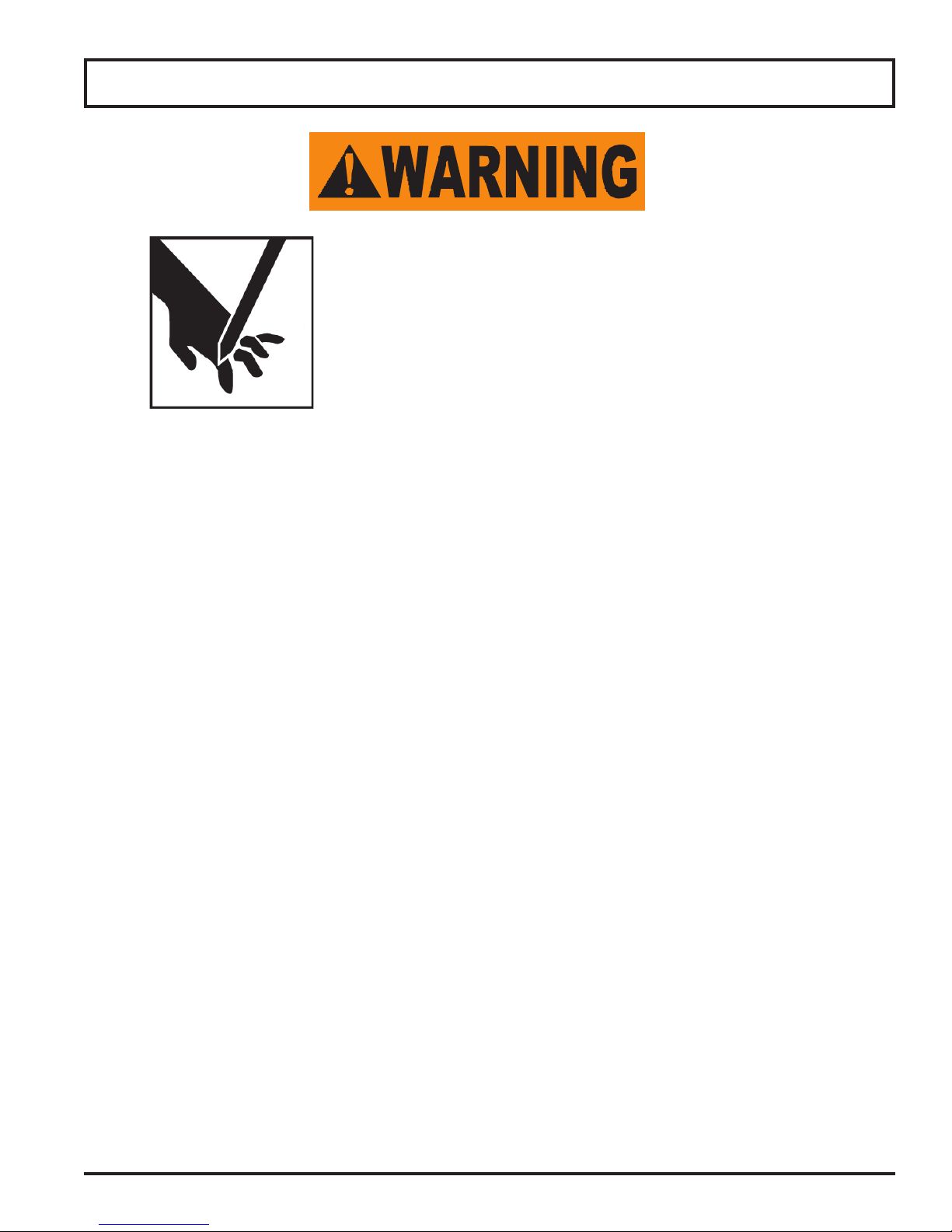

SHARPKNIFEBLADE

TOAVOIDSERIOUSPERSONALINJURYTOTHESLICEROPERATORANDCUSTOMERS:

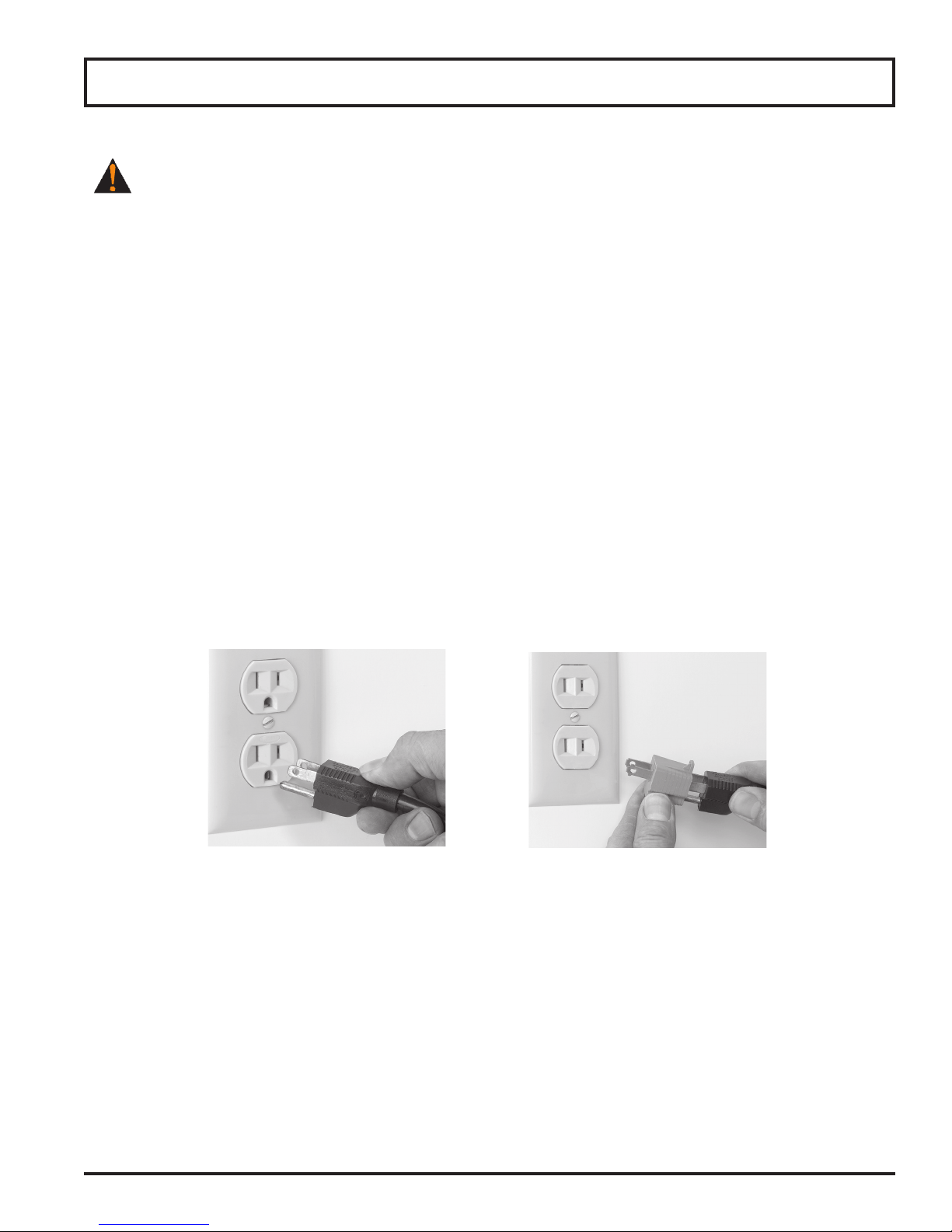

• BEFORECLEANING,SHARPENING,SERVICINGORREMOVINGANYPARTS,always turn slicer off,

turn the slice thickness dial clockwise until it stops, and unplug the power cord.

• NEVERattempt to clean slicer with the knife running.

• NEVERattempt to remove the knife or knife ring guard from the slicer. They must remain on the

slicer for proper operation, sharpening, and cleaning.

To prevent illness or death caused by the spread of food-borne pathogens, it is important to

properly clean and sanitize the entire slicer as any surface of the slicer can become contaminated.

It is the responsibility of the slicer owner/operator to follow all guidelines, instructions and laws as

established by your local and state health departments and the manufacturers of chemical sanitizers.

Onceyourslicermakescontactwithfoodproduct,theentireslicer,includingremovableparts,must

bethoroughlycleanedandsanitized.Thisprocessistoberepeatedatleastevery4hoursusing

theseproceduresandinformation;andmustcomplywithadditionallawsfromyourstateandlocal

healthdepartments.

As with all food contact surfaces, it is extremely important to properly sanitize the entire slicer and toclosely

followtheinstructionsonyourquaternarysanitizercontainertoensurepropersanitationisachieved

tokillpotentiallyharmfulbacteria.

NOTE: It may be desirable to wear non-cutting safety gloves during the cleaning operation.

IMPORTANT:Ifachemicalsanitizerotherthanchlorine,iodineorquaternaryammoniumisused,itshallbe

appliedinaccordancewiththeEPA-registeredlabeluseinstructions.Excessive amounts of sanitizer and use

of products not formulated for stainless steel or aluminum may VOID your warranty.

Sanitizer concentration shall comply with section 4-501.114, Manual and Mechanical Warewashing Equipment,

Chemical Sanitization - Temperature, pH, Concentration, and Hardness of the FDA Food Code.

Formoreinformationonproperkitchenandequipmentsanitation,visitwww.servsafe.comprovidedbythe

NationalRestaurantAssociation(NRA).

• DONOThose down, pressure wash, or pour water on the slicer.

• NEVERuse a scrubber pad, steel wool, or abrasive material to clean the slicer.

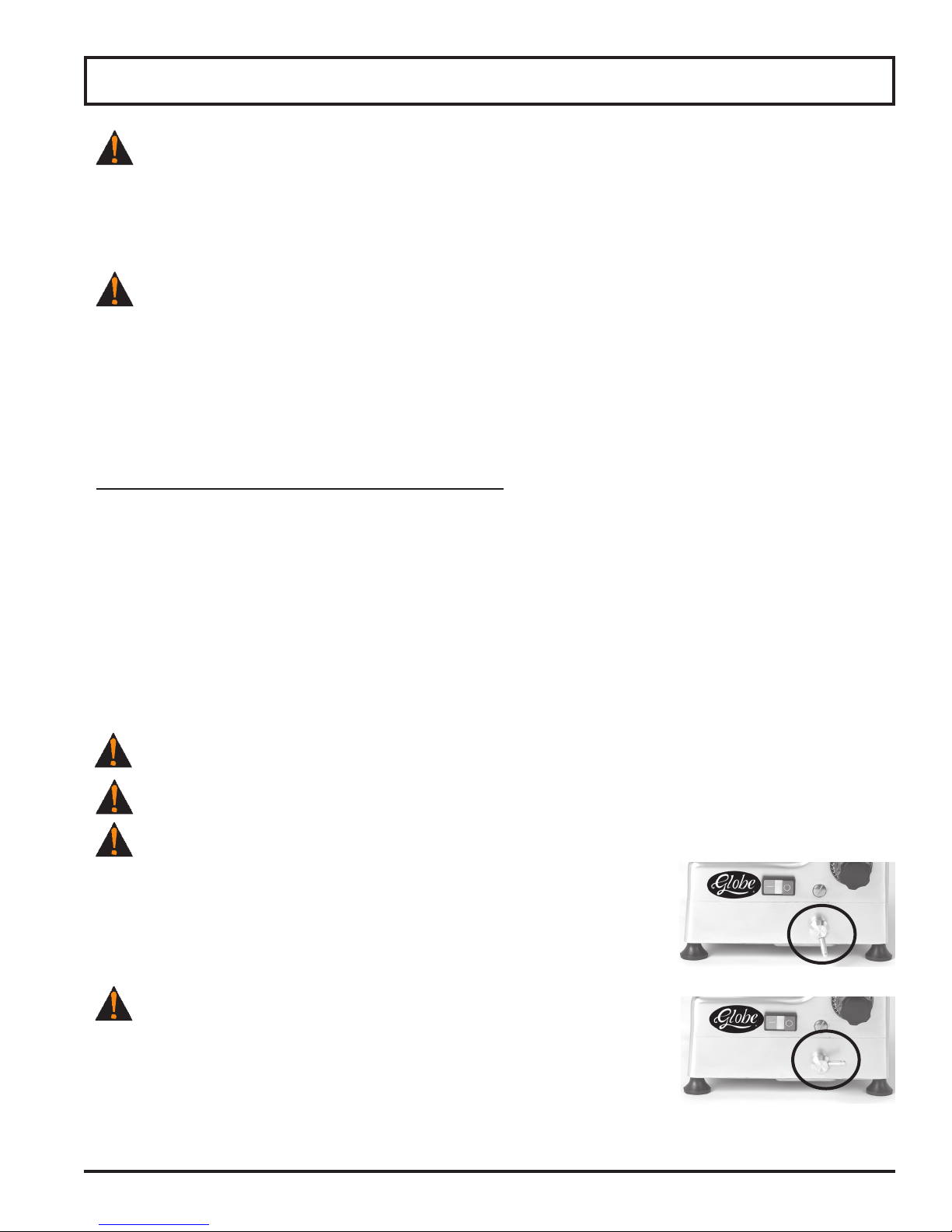

• NEVERtrytoclean,sharpen,oroperatetheslicerwiththeliftleverintheraisedposition

(automaticslicersonly).

• ALWAYSturnslicerOFFandunplugthepowercordBEFOREcleaning.

• Itisextremelyimportanttofollowtheinstructionsonthesanitizercontainertoensure

propersanitationisachieved.Allowthepartstoairdrybeforeplacingthembackontheslicer!

DONOT use bleach, products containing sodium hypochlorite or other caustic/strong detergents on the slicer base

or removable parts. These products will discolor and destroy the parts.

Slicer components are easily disassembled without the use of special tools. It may be desirable to wear non-cutting

safety gloves during the cleaning operation.