2 D5015 - SIL 2 Repeater Power Supply G.M. International ISM0397-3

General Description:

The single channel Repeater Power Supply, D5015SS and D5015SK modules, is a high integrity analog input interface suitable for applications requiring SIL 2 level (according to IEC

61508:2010 Ed.2) in safety related systems for high risk industries.

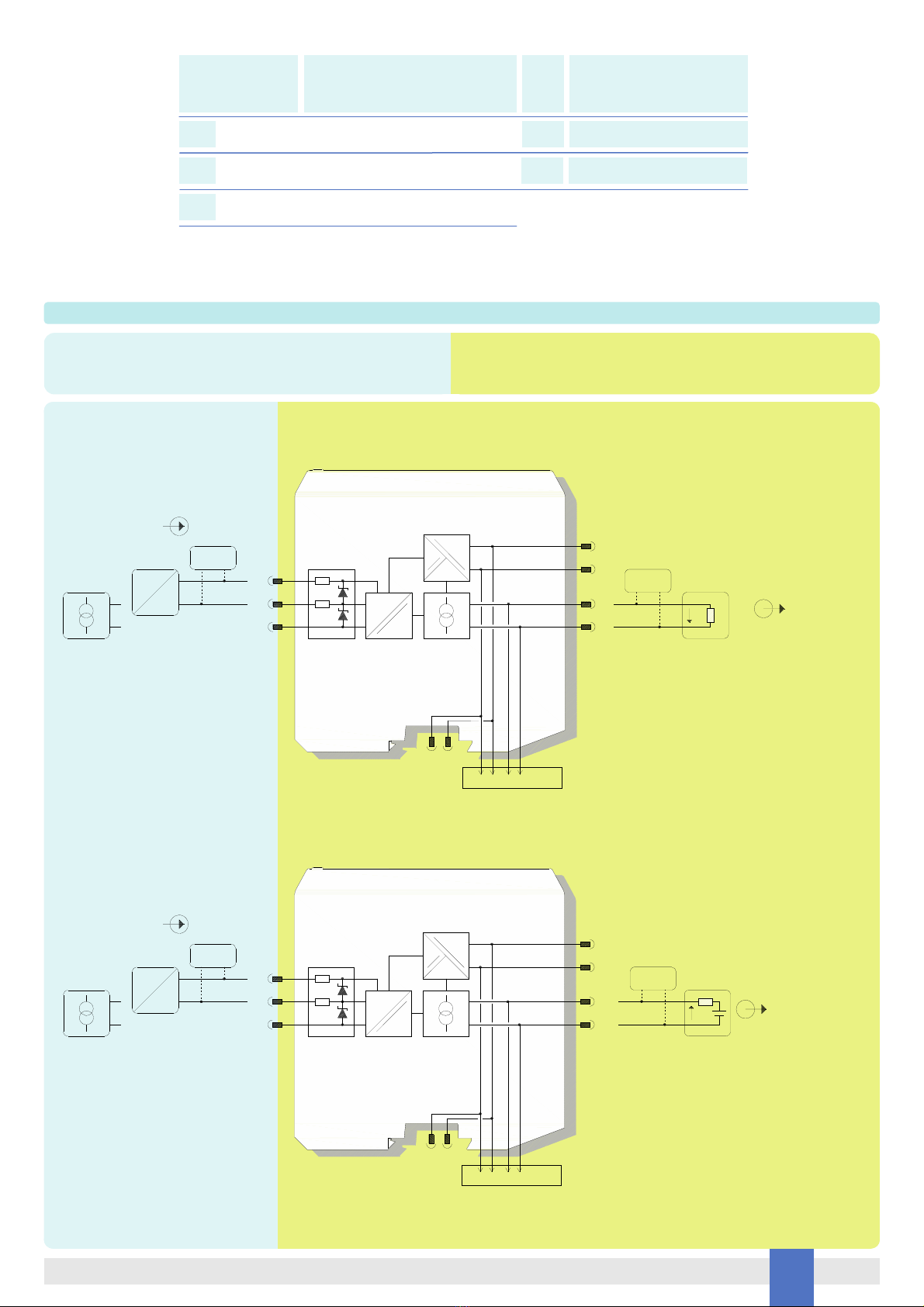

Provides a fully floating dc supply for energizing conventional 2 wires passive 4-20 mA or 4 wires (active) transmitters located in Hazardous Area, and repeats the current in floating

circuit to drive a Safe Area load. The circuit allows bi-directional communication signals, for HART® transmitters.

Mounting on standard DIN-Rail, with or without Power Bus, or on customized Termination Boards, in Safe Area / Non Hazardous Location or in Zone 2 / Class I, Division 2 or Class I,

Zone 2.

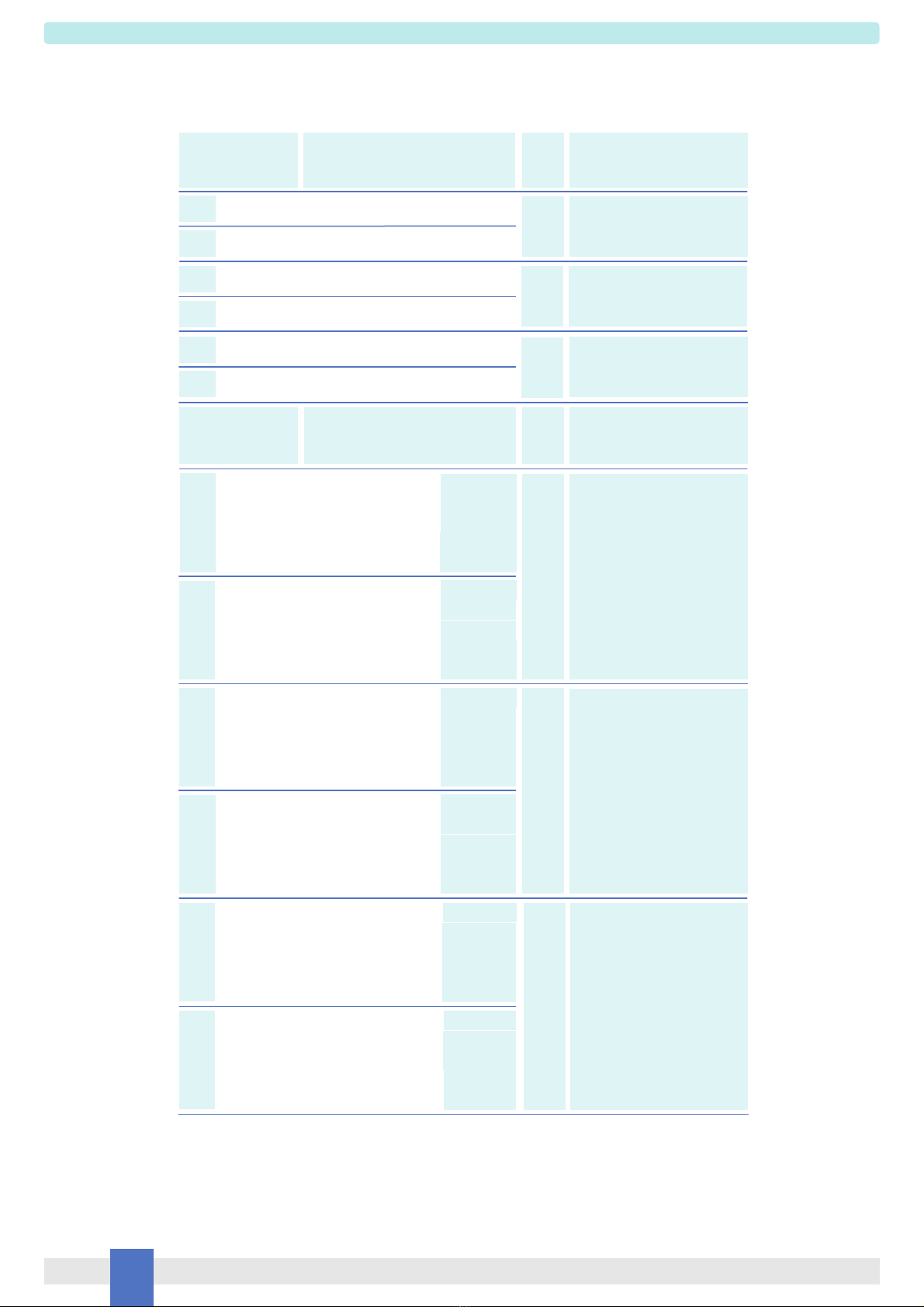

D5015SS: Single channel, source output.

D5015SK: Single channel, sink output.

Functional Safety Management Certification:

G.M. International is certified by TUV to conform to IEC61508:2010

part 1 clauses 5-6 for safety related systems up to and included SIL 3.

Technical Data

Characteristics

Supply:

24 Vdc nom (18 to 30 Vdc) reverse polarity protected, ripple within voltage limits 5 Vpp, 2 A time lag fuse internally protected.

Current consumption @ 24 V: 50 mA with 20 mA output typical.

Power dissipation: 0.90 W with 24 V supply voltage and 20 mA output typical.

Isolation (Test Voltage):

I.S. In/Out 2.5 KV; I.S. In/Supply 2.5 KV; Out/Supply 500 V.

Input:

4 to 20 mA (separately powered input, voltage drop 0.5 V) or

4 to 20 mA (2 wires Tx current limited at 25 mA), reading range 0 to 24 mA.

Transmitter line voltage:

16.0 V typical at 20 mA with max.

Output:

4 to 20 mA, on max. 550 load in source mode (typical 12 V compliance);

V min. 8 V at 0 load V max. 30 V in sink mode, current limited at 25 mA.

Response time: 5 ms (0 to 100 % step change).

Performance:

Ref. Conditions 24 V supply, 250 load, 23 ± 1 °C ambient temperature.

Calibration accuracy: ± 0.1 % of full scale.

Linearity error: ± 0.05 % of full scale.

Supply voltage influence: ± 0.02 % of full scale for a min to max supply change.

Load influence: ± 0.02 % of full scale for a 0 to 100 % load resistance change.

Temperature influence: ± 0.01 % of full scale on zero and span for a 1°C change.

Compatibility:

CE mark compliant, conforms to Directives:

2014/34/EU ATEX, 2014/30/EU EMC, 2014/35/EU LVD, 2011/65/EU RoHS.

Environmental conditions:

Operating: temperature limits – 40 to + 70 °C, relative humidity 95 %, up to 55 °C.

Max altitude: 2000 m a.s.l.

Storage: temperature limits – 45 to + 80 °C.

Safety Description:

ATEX: II 3(1) G Ex ec [ia Ga] IIC T4 Gc, II (1) D [Ex ia Da] IIIC, I (M1) [Ex ia Ma] I

IECEx: Ex ec [ia Ga] IIC T4 Gc, [Ex ia Da] IIIC, [Ex ia Ma] I

UL: NI / I / 2 / ABCD / T4, AIS / I, II, III / 1 / ABCDEFG, AEx nA [ia Ga] IIC T4 Gc; C-UL: NI / I / 2 / ABCD / T4, AIS / I, II, III / 1 / ABCDEFG, Ex nA [ia Ga] IIC T4 Gc X

associated apparatus and non-sparking electrical equipment.

Uo/Voc = 26.8 V, Io/Isc = 92 mA, Po/Po = 614 mW at terminals 7-8,

Uo/Voc = 1.1 V, Io/Isc = 56 mA, Po/Po = 16 mW at terminals 8-11,

Ui/Vmax = 30 V, Ii/Imax = 128 mA, Ci = 0 nF, Li = 0 nH at terminals 8-11,

Um = 250 Vrms or Vdc, -40 °C Ta 70 °C.

Approvals:

BVS 20 ATEX E 023 X conforms to EN60079-0, EN60079-11, EN60079-7.

IECEx BVS 20.0016X conforms to IEC60079-0, IEC60079-11, IEC60079-7.

UL & C-UL E222308 conforms to UL 61010-1, UL913, UL 60079-0, UL60079-11, UL60079-15, UL121201 for UL

and CAN/CSA C22.2 No. 61010-1-12, CSA-E60079-0, CSA-E60079-11, CSA-E60079-15 and CSA-C22.2 No. 213 for C-UL.

TUV Certificate No. C-IS-272994-01 SIL 2 conforms to IEC61508:2010 Ed. 2.

TÜV Certificate No. C-IS-236198-09, SIL 3 Functional Safety Certificate conforms to IEC61508:2010 Ed.2, for Management of Functional Safety.

Mounting:

EN/IEC60715 TH 35 DIN-Rail, with or without Power Bus or on customized Termination Board.

Weight: about 130 g.

Connection: by polarized plug-in disconnect screw terminal blocks to accommodate terminations up to 2.5 mm2(13 AWG).

Location: installation in Safe Area/Non Hazardous Locations or Zone 2, Group IIC T4 or Class I, Division 2, Group A,B,C,D, T4 or Class I, Zone 2, Group IIC, T4.

Protection class: IP 20.

Dimensions: Width 12.5 mm, Depth 123 mm, Height 120 mm.

FSM

SIL 3