PSD1220 & PSD1220-098 - SIL 3 Power Supply, 24Vdc, 20 A, Zone 2, DIN Rail Mounting G.M. International ISM0370-3

4

Reasons for using an Ideal Diode-OR Controller circuit, in N+1 redundant power supply applications with high availability systems

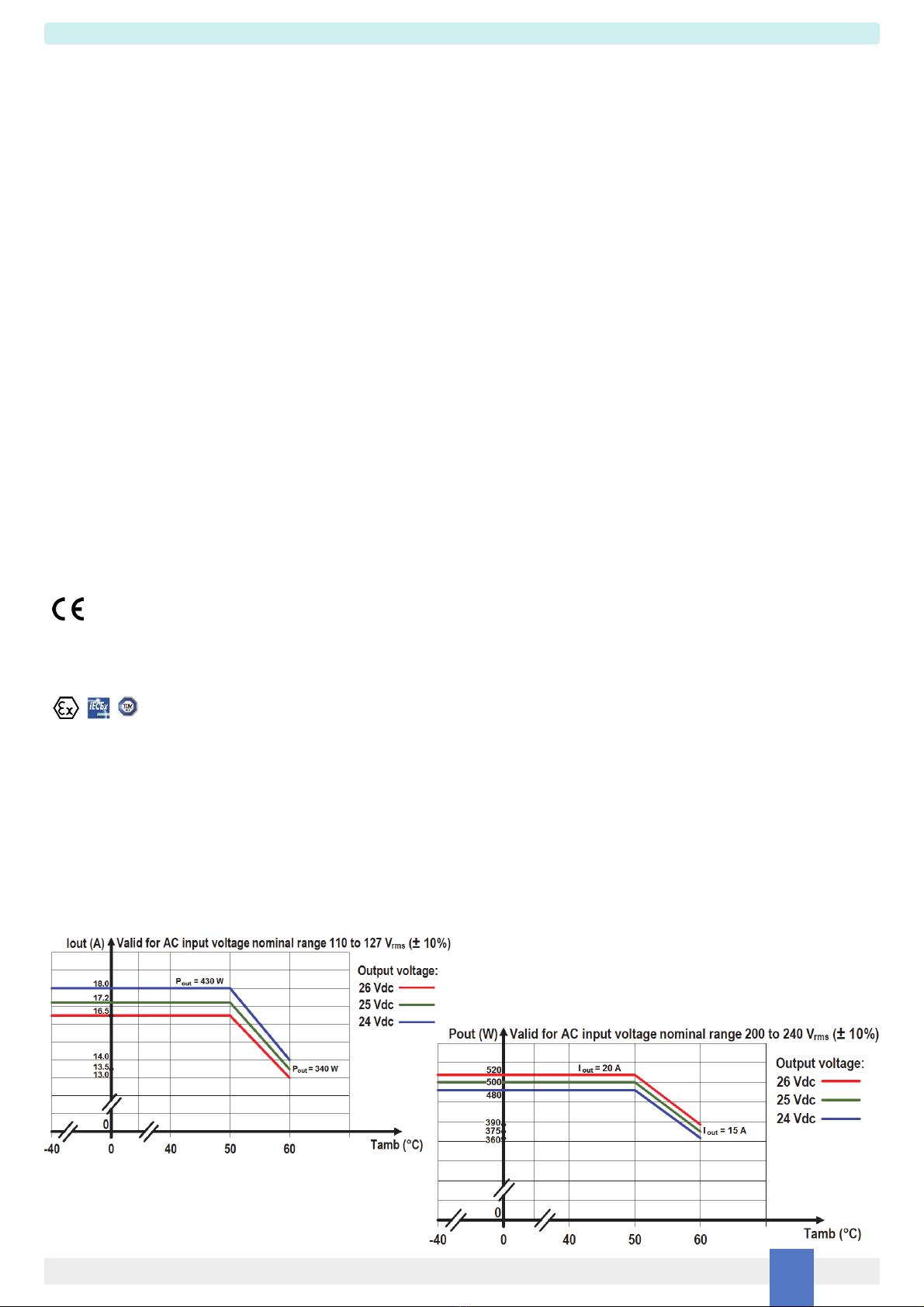

High availability systems often employ power supply modules connected in parallel to achieve redundancy and enhance system reliability.

ORing diodes have been a popular means of connecting these supplies at a point of load. The disadvantage of this approach is the forward voltage drop and resulting efficiency loss.

This drop reduces the available supply voltage and dissipates significant power.

Replacing Schottky diodes with N-channel MOSFETs reduces power dissipation and eliminates the need for expensive heat sinks or large thermal layouts in high power applications.

In the Ideal Diode-OR Controller circuit (active ideal diode), the voltage across source and drain is monitored by the IN and OUT pins, and GATE pin drives the MOSFETs to control

their operation. In effect the MOSFET source and drain serve as the anode and cathode of an ideal diode.

In the event of a power supply failure, for example if the output of a fully loaded supply is suddenly shorted to ground, reverse current temporarily flows through the MOSFETs that are

ON. This current is sourced from any load capacitance and from the other supplies. The active ideal diode quickly responds to this condition turning off the MOSFETs in about 0.5µs,

thus minimizing disturbance and oscillations to the output bus.

Using ORing diodes, to parallel two, or more, 24VDC power supply modules for redundancy, one Schottky diode is used for each module. The voltage drop across the diode can reach

about 0.8 V at 20 A, this means about 16 W dissipation for each module. Then, if two 20 A paralleled modules are used for full 20 + 20 A redundancy, a total power of about 32 W is

dissipated for this purpose. This reduces efficiency, reliability and increases space for heat sinks. Moreover, in case of module failure, diodes take time to recover and consequently

they do not preserve the load from transients during the backup operation.

To avoid all these problems G.M. International has introduced, in the new PSD1220 or PSD1220-098 Power Supply System, the use of active ideal diodes.

The MOSFETs resistance for active ideal diodes is about 1 mΩresulting in 0.4 W dissipation for each power module. Then, if two 20 A paralleled modules are used for full

20 + 20 Amp redundancy, a total power of about 0.8 W is dissipated for the purpose resulting in about forty times less dissipation compared to Schottky diodes solution.

This increases efficiency, reliability, availability and reduces space for heat sinks.

This circuit provides also very smooth voltage switchovers without oscillations with fast turnoff, minimizing reverse current transients.

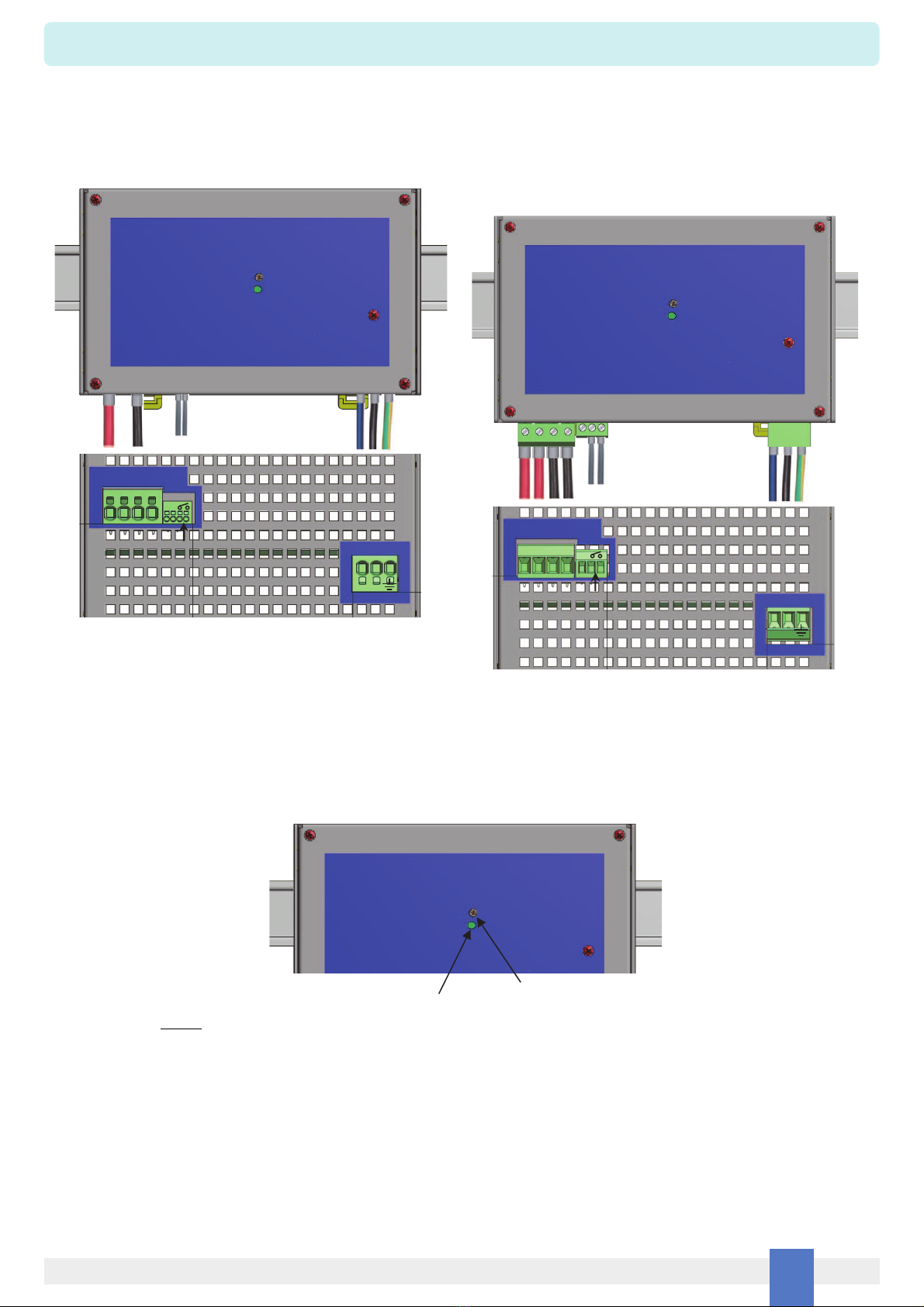

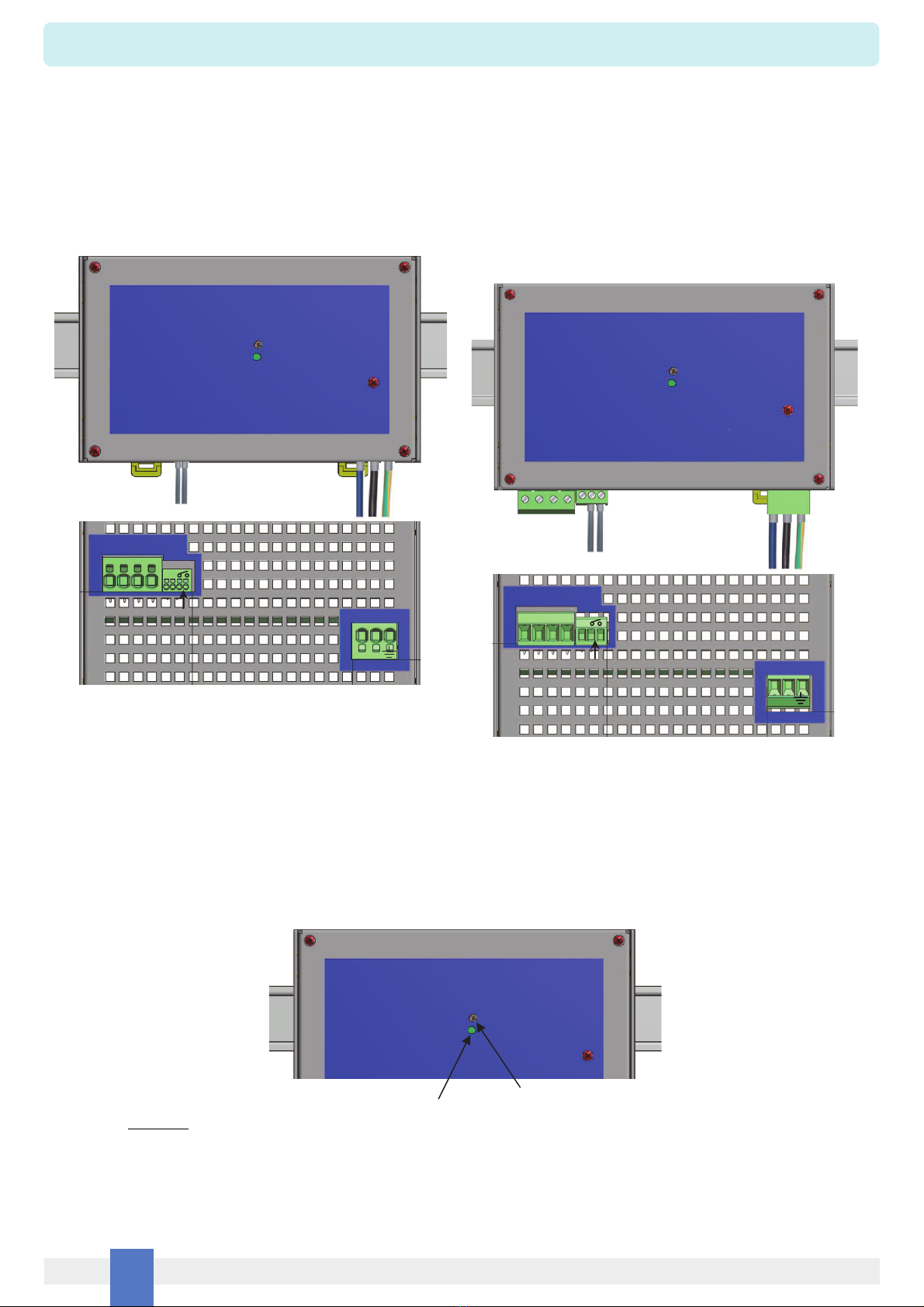

Output voltage setting - Fault indications

The output voltage can be set from 23.6 to 26.1 Vdc by a front panel trimmer.

Under voltage threshold is set to 22 V, while Over voltage threshold is set to 28 V.

A front panel power ON green LED signals that mains voltage is applied to the power module and normal DC output voltage is present on DC output terminal block.

Power module Fault conditions are signaled by opening contact of NE relay (in normal condition contact is closed) on the “Fault” terminal block. Faults can be:

Under voltage Vout < 22 V.

Over voltage Vout > 28 V.

In absence of under / over voltage fault, the green Power ON LED is ON if output voltage is within 22 V - 28 V range

If output voltage goes below 22 V, the green Power ON LED blinks and remains steady for values lower than 22.5 V.

If output voltage goes over 28 V, the green Power ON LED is OFF and remains steady for values higher than 27.5 V.

After under / over voltage fault, coming back to normal condition, the green Power ON LED is ON if output voltage is within 22.5 V - 27.5 V range.

Warning

Storage

Disposal

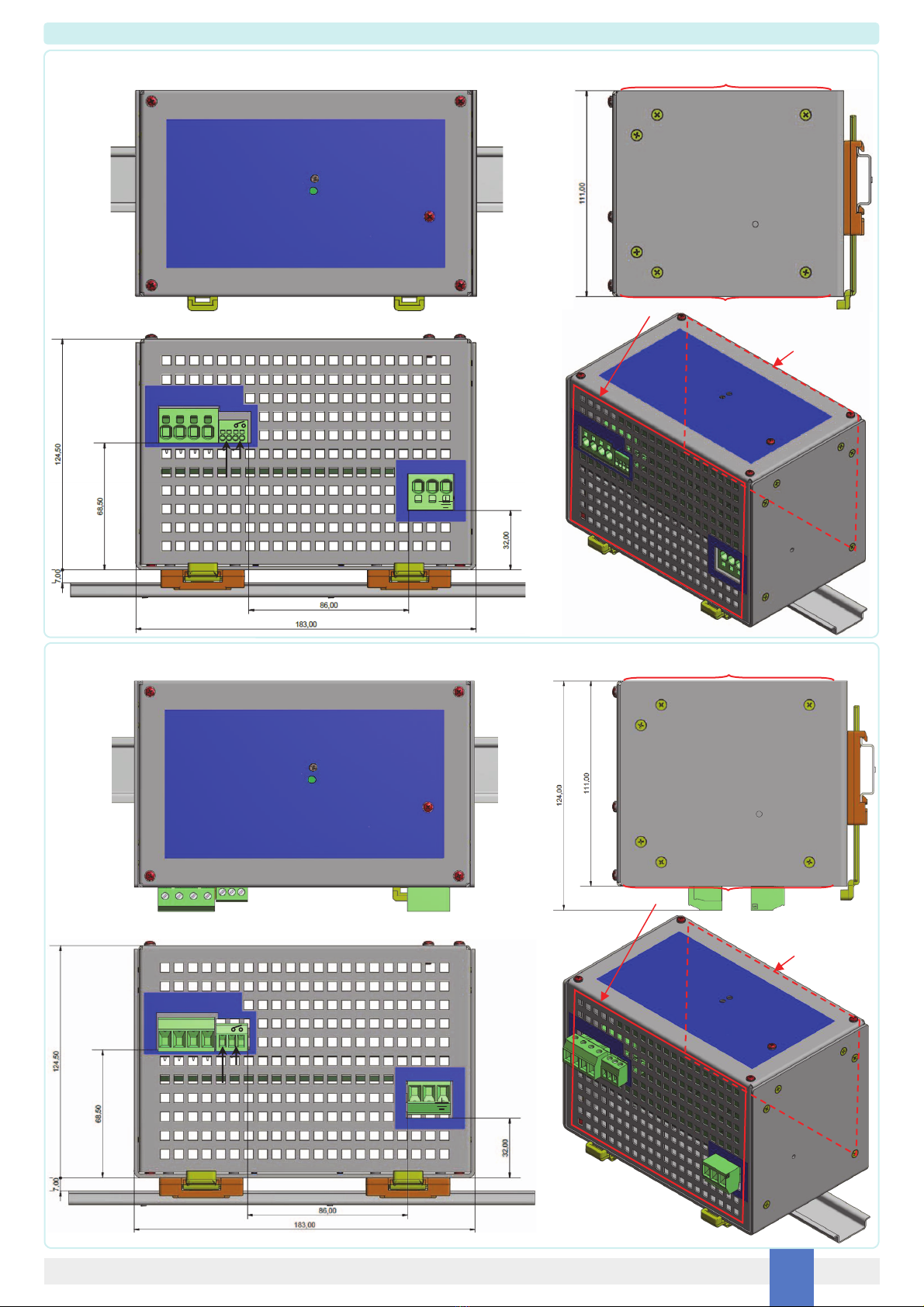

PSD1220 and PSD1220-098 are isolated Switching Power Supply units located in Safe Area or Zone 2, Gas Group IIC, Temperature T4 Hazardous Area within the specified

operating temperature limits -40°C ≤Tamb ≤+60°C and mounting conditions.

Read installation manual before operating the unit. Failure of proper installation or use of the equipment may damage the unit or cause severe personal injury.

PSD1220 and PSD1220-098 must be installed, wired, operated and maintained only by qualified personnel, in accordance to the relevant national/international installation

standards (e.g. IEC/EN60079-14 Explosive atmospheres - Part 14: Electrical installations design, selection and erection), following established installation guide lines.

PSD1220 and PSD1220-098 must be placed in an enclosure with IP4X protection degree when used in locations providing adequate protection against the entry of solid foreign

objects or water, capable of impairing safety, or be placed in an enclosure with IP54 protection degree for other locations. Substitution of components may impair suitability for

Zone 2.

Explosion Hazard: to prevent ignition of flammable or combustible atmospheres, disconnect power and wait that green power-on LED is OFF before servicing or unless area is

known to be nonhazardous. Remove power before opening the case.

Clean only with dry cloth.

Green Power ON LED of power supply unit: check that green LED is OFF before disconnecting power supply.

Failure to properly installation or use of the equipment may risk to damage the unit or severe personal injury. The unit cannot be repaired by the end user and must be returned

to the manufacturer or his authorized representative. Any unauthorized modification must be avoided.

If after an incoming inspection the unit is not installed directly on a system (parts for spare or expansion with long storage periods) it must be conveniently stocked.

Stocking area characteristics must comply with the following parameters:

Temperature -40 to +70 °C, the -45 to +80 °C is meant for limited periods, -10 to +30 °C is preferred.

Humidity 0 to 95 %, 0 to 60 % humidity is preferred.

Vibration: no prolonged vibration should be perceivable in the stocking area to avoid loosening of parts or fatigue ruptures of components terminals.

Pollution: presence of pollutant or corrosive gases or vapors must be avoided to prevent corrosion of conductors and degradation of insulating surfaces.

The product should not be disposed with other wastes at the end of its working life. It may content hazardous substances for the health and the environment, to prevent possible harm

from uncontrolled waste disposal, please separate this equipment from other types of wastes and recycle it responsibly to promote the sustainable reuse of material resources.

This product should not be mixed with other commercial wastes for disposal.