2

Contents

1. Introduction................................................................................................................................................4

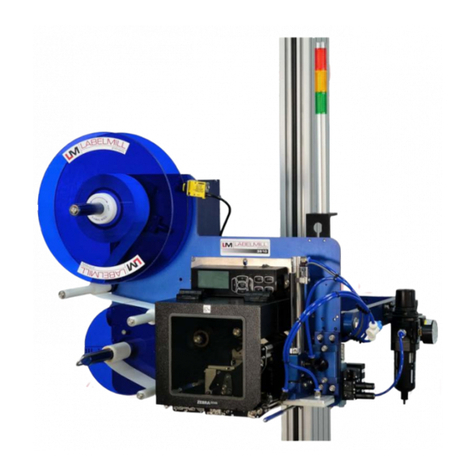

1.1 Overview ...................................................................................................................................................4

1.2 Applicator Specifications Summarized .....................................................................................................4

3. Basic Safety Precautions.............................................................................................................................5

3.1 Coverage.............................................................................................................................................5

3.2 Following the instructions in this operating manual ..........................................................................5

3.3 Possible device handling risks.............................................................................................................5

3.4 Environmental conditions of the device operation ............................................................................5

3.5 Occupational health and safety rules .................................................................................................6

3.6 Safety instructions ..............................................................................................................................6

3.7 Never: .................................................................................................................................................7

3.8 Applied harmonized standards and the safe use of electrical appliances ..........................................7

3.9 The possible risks of electric shocks if working with the applicator...................................................8

3.10 Configuring the pneumatic unit, safety ..............................................................................................8

4. Contents of delivery - what’s in the box? ...................................................................................................9

4.1 Standard configuration with 170 mm effective stroke.......................................................................9

3.2 Checking the box contents (AG-3000-110060 / AG-3000-110100) ..........................................................9

3.2.1 Box 1: Printer + Accessories ..............................................................................................................9

3.2.2 Box 2: Applicator components ....................................................................................................... 11

5. Assembling the system ............................................................................................................................ 13

5.1 Required Tools................................................................................................................................. 13

5.2 Assembling the stand ...................................................................................................................... 13

5.3 Installing the internal rewinder in the printer................................................................................. 17

5.4 Installing the applicator interface.................................................................................................... 19

5.5 Integrating the printer and applicator unit ..................................................................................... 21

6. Operating your AG3000T(-LS).................................................................................................................. 26

6.1 Print & apply cycle: the basics ......................................................................................................... 26

6.2 Printer configuration for applicatoruse........................................................................................... 26

6.2.1 Power on the printer ................................................................................................................... 26

5.2.2 Firmware......................................................................................................................................... 27

5.2.3 Setting the printer in applicatormode ........................................................................................... 27

5.2.4 Formatting the applicator interface (!)........................................................................................... 29

5.2.5 Smart backfeed............................................................................................................................... 29

5.2.6 Create a label and load media ........................................................................................................ 29

6.3 Putting the applicator into service .................................................................................................. 29

6.3.1 Air supply ..................................................................................................................................... 29