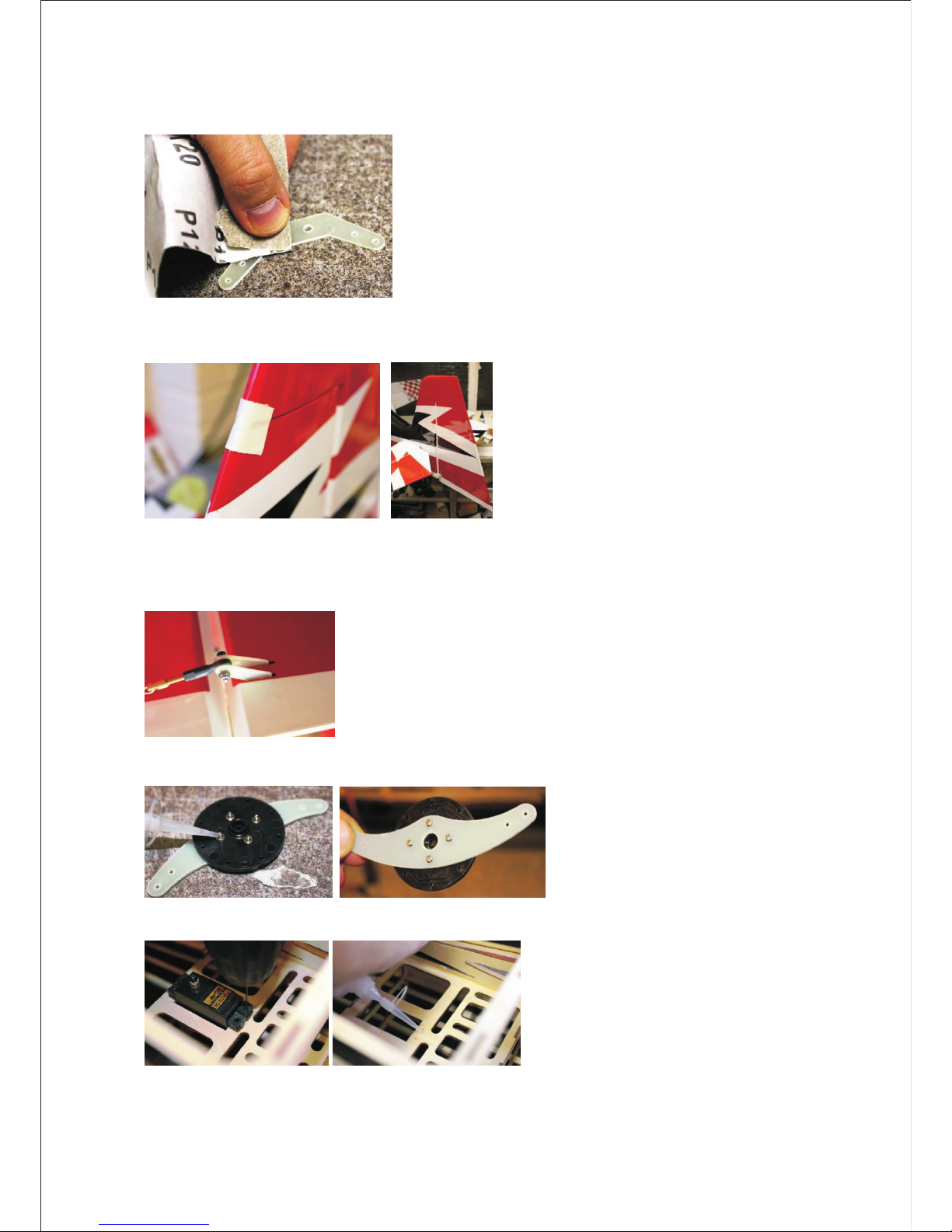

● Sand the area on the horn that fits inside the rudder so the glue bonds better

● Glue the rudder hinges into both the rudder and fin using epoxy glue. Remember to

use Vaseline , use tape to keep it in alignment.on the hinge joint. While drying

● Glue the rudder horns through the rudder with epoxy ;wipe off excess glue while it is

wet. Use the and bolt while gluing to maintain alignment. While still movable ,ball joint

measure that the same ,amount pushes out each side. Care needs to be taken here

otherwise your rudder geometry will be incorrect.

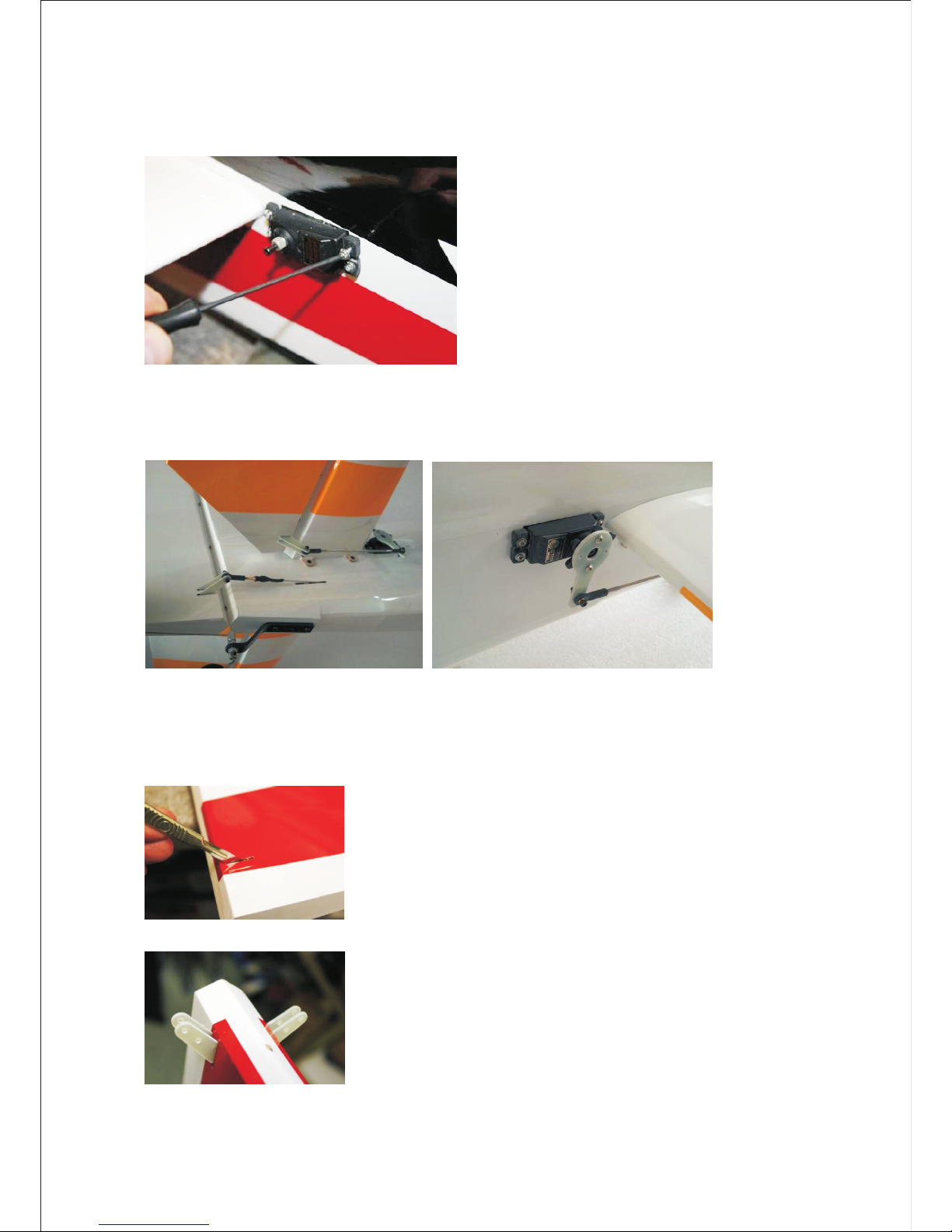

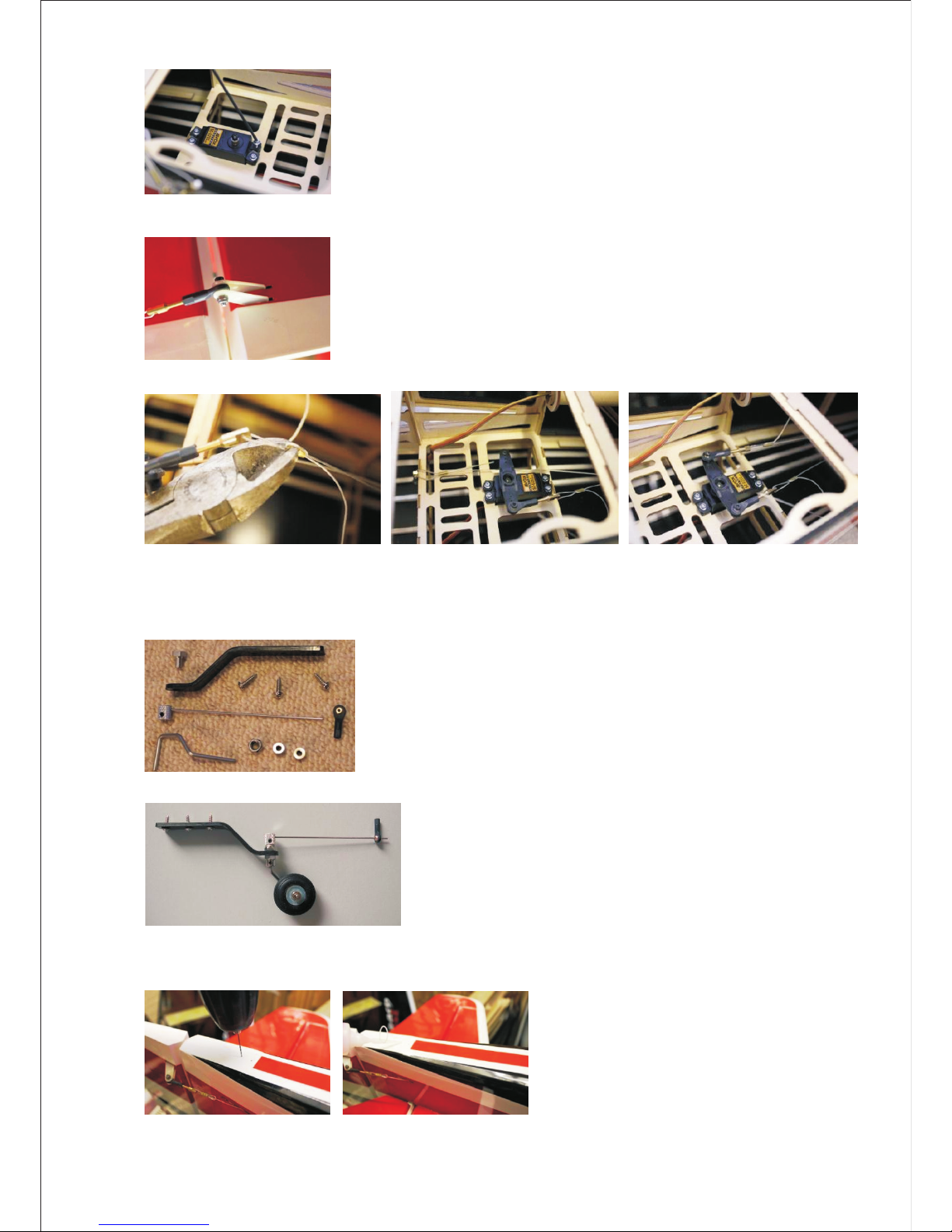

● Assemble the rudder servo control arm as below, drill holes for screws and use C.A

glue to stop the nuts from coming loose.

● Fit the rudder servo and drill holes using a fine drill for the servo screws; drop thin C.A glue into the

holes to strengthen the wood.

● Using servo screws, fix the servo in place; note that the spline is towards the front of the plane