4© 2019 Copyright All Rights Reserved

DDM101 Duel Driver Module 1.15.19 PIB 4134 F

FUEL BALANCE ADJUSTMENTS

e FUEL BALANCE adjustment allows for equalization of the fuel being delivered by

each actuator. With the engine running at no load, measure the DC voltage output of the

feedback sensors from each actuator. Voltage measurement for Actuator 1 is taken across

Terminals 13 and 14. Voltage measurement for Actuator 2 is taken across Terminals 20

and 21. Both voltage measurements should have an operational range of 1 to 4 VDC.

If the voltage readings are not equal, adjust the FUEL BALANCE potentiometer on the

DDM101 until the voltage readings are equalized and the exhaust temperatures are

balanced.

GOVERNOR GAIN ADJUSTMENT

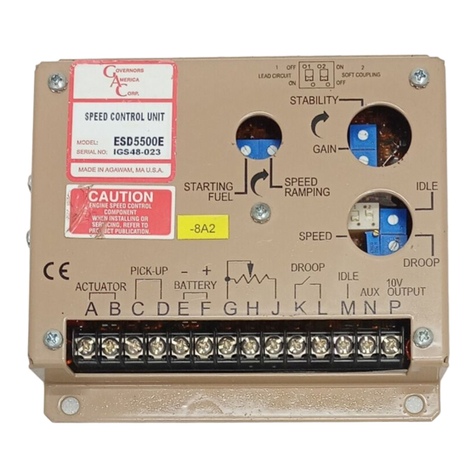

With the engine running at rated speed, the PID system in the ESD can be adjusted for

optimum performance (see the ESD’s manual).

For best performance, the ESD’s GAIN adjustment should be set between 40-60% of

range. If the ESD’s GAIN adjustment is below 25% the DDM101’s GOVERNOR GAIN

adjustment should be rotated CCW to a lower setting. e ESD’s PID settings will have

to be readjusted for optimum transient performance (refer to the ESD’s manual).

Adjusting the DDM101 can also be accomplished by analyzing the ESD’s PWM voltage

input to Terminals 25 and 26 on the DDM101. e desirable voltage reading between

Terminals 25 and 26 should measure 7 VDC at no load and 14 VDC at full load. If the

measured voltage is lower than the desired range, the DDM101’s GOVERNOR GAIN

adjustment is set too high and should be rotated CCW to a lower setting. e voltage

across Terminals 25 and 26 on the DDM101 should increase. If the measured voltage is

lower than the desired range, the DDM101’s GOVERNOR GAIN adjustment is set too

low and should be rotated CW to a higher setting. e voltage across Terminals 25 and

26 on the DDM101 should decrease.

EXHAUST TEMP DIFFERENCE MONITORING AND CONTROL

e DDM101 requires the use of exhaust temperature thermocouples to balance the load

precisely with the dynamic balancing function.

Placement of thermocouples in the exhaust gas stream does not

guarantee that equal measurements provide equal power from each

bank. Exhaust temperature is, however, a good indication of balance and the exhaust

temperature control loop will actively trim the system.

With the installation of two industrial rated Type K type thermocouples in the exhaust

pipe of each bank, the DDM101 can measure and track two exhaust temperatures.

e thermocouple adjustments (THERMOCOUPLE 1 & THERMOCOUPLE 2) are

calibrated at the factory to receive equal input signals from the thermocouples. If a

dierence in either bank’s exhaust temperature is measured by the DDM101, the

control loop will readjust the fuel balance automatically to minimize the dierence. If

a measured dierence is still found, the operator can manually reduce the unbalance

and increase the temp control loop authority by a CW rotation of the TEMP. BAL GAIN

adjustment.

If at any time, one or both of the thermocouples signals are lost (open circuit detected)

the TC 1 or TC 2 fault LED will light and the balancing function will shut o. (see

TABLE 7)

Do not alter the factory settings of THERMOCOUPLE 1 or

THERMOCOUPLE 2 adjustments unless a signicant unbalance

exists. If a balance does occur, rst try to correct the issue using the standard mechanical

and electronic balancing methods described above. If a problem persists, determine

which exhaust channel is higher in temperature and adjust the bank’s THERMOCOUPLE

adjustment CCW to equalize the exhaust temperature. Adjusting the cooler banks

THERMOCOUPLE adjustment CW will equalize the exhaust temperature as well.

CAUTION

WARNING

RACK POSITION-MONITORING

With power applied to the DDM101 and before starting the engine, measure the voltage

at the Terminals 16(+) & 17(-). It should be adjusted to zero Volts by the Actuator 1

Oset (A1 O) for Actuator 1 (closed position) and at Terminals 18(+) & 19(-) by the

Actuator 2 Oset (A2 O). At maximum positions the voltage at the above-mentioned

terminals should be 1 Volt and can be adjusted by Actuator 1 Gain (A1 G) and Actuator

2 Gain (A2 G) respectively. To manually open the actuator, remove the wire from

Terminal A on the

ESD

and connect the wire to Terminal F on the

ESD

. Adjust A1 G

and A2 G for 1 Volt output at Terminal 16 and Terminal 18. Reconnect the wire back

to Terminal A on the

ESD.

LED FUNCTION

ACT 1 Actuator drive circuit 1 is receiving a drive signal from the control.

ACT 2 Actuator drive circuit 2 is receiving a drive signal from the control.

TC 1 FAULT ermocouple 1 has a fault or open circuit.

TC 2 FAULT ermocouple 2 has a fault or open circuit.

EXHAUST

TEMP 1

Unbalances in exhaust temperatures; control is actively trimming fuel to actuator 1 to

rebalance the system.

EXHAUST

TEMP 2

Unbalances in exhaust temperatures; control is actively trimming fuel to actuator 2 to

rebalance the system.

GOV DRIVE Drive signal from external governor is being removed to open up the throttle.

TABLE 7:

CAUTION e sensor is easily damaged so take caution when installing the sensor.

Use Type-K wire and connectors only. Do not mix dissimilar metals.

NOTE e sensor includes a weld bung. Drill and weld, then insert sensor

using below procedure.

EGT TEMPERATURE SENSOR INSTALLATION PROCEDURE

1. Apply thread sealant to the sensor.

2. read the sensor nger tight into the location from the application consid-

erations.

3. Once complete, turn the sensor 2 full turns past nger tight.

NOTE

e exhaust temperature probe is located in the engine exhaust outlet

as near as possible to the point where all of the cylinders merge. Alter-

natively, the sensor can be placed in the manifold outlet pipe. A weld

bung or tapped hole must be used and care should be taken such that

the tip of the probe is well within the outlet exhaust ow. e sensor

is mounted via a 1/8 in. NPT tting. Drill and tap the determined

mounting location using the provided dimensions.

Exhaust Gas Temperature Sensors, part number STE101: Type K ermocouple

with 1200°F (650°C) Maximum. Mating Connector Included.