SAFETY

Our compliments for your excellent choice. Your new

electromechanical gear motor has been produced according to a high

quality and a strict reliability, that's why it will assure you long-lasting

performances.

This booklet will offer you all the pieces of information you may need to

install your gear motor and to safeguard your safety.

However, the caut on s unquest onably nd spensable and

noth ng s better than prevent ng acc dents.

ll our products have been made in conformity with the regulations in

force.

WARNING: any repair or adjustment of the working machinery is

strictly prohibited unless all the necessary precautions (electrical

supply disconnected and motor off) have been taken in order to avoid

possible accidents.

WARNING: any repair must be carried out by qualified people.

ll moving mechanisms must be provided with suitable protections.

WARNING: Keep the automatic controls out of the reach of childrens.

The controls must be installed at a minimum high of 1,5 mt. from the

ground surface and out of the work of mobile parts.

WARNING: command pulses must be given from positions where the

gate is visible.

WARNING: use the transmitters only if you can see the gate.

WARNING: GR Srl is not responsible for possible damages or injuries

to people, objects or animals, caused by any unauthorised modification

of the product.

Keep scrupulously this booklet in a suitable place well known by all the

interested people.

In order to make the automation work efficiently; the gate to automate

must have the following characteristics:

- it must be balanced;

- it must oscillate fluently;

- you have to carry out the manual closing and opening the gate

without any effort;

- remember that the motorization has been planned in order to help you

use the gate. This means that it does not resolve the problems caused

by an inadequate installation or by a poor upkeep of the gate.

SAFETY RULES

During the installation and the use of the automation, you have to pay

attention to the following safety rules:

- Security distance!

- Mechanism in movement!

- Do not install the automation in places with presence of iniammable

gasses!

- Electric shock!

- Use the gloves!

- Use glasses for welding!

- Keep the protection carter!

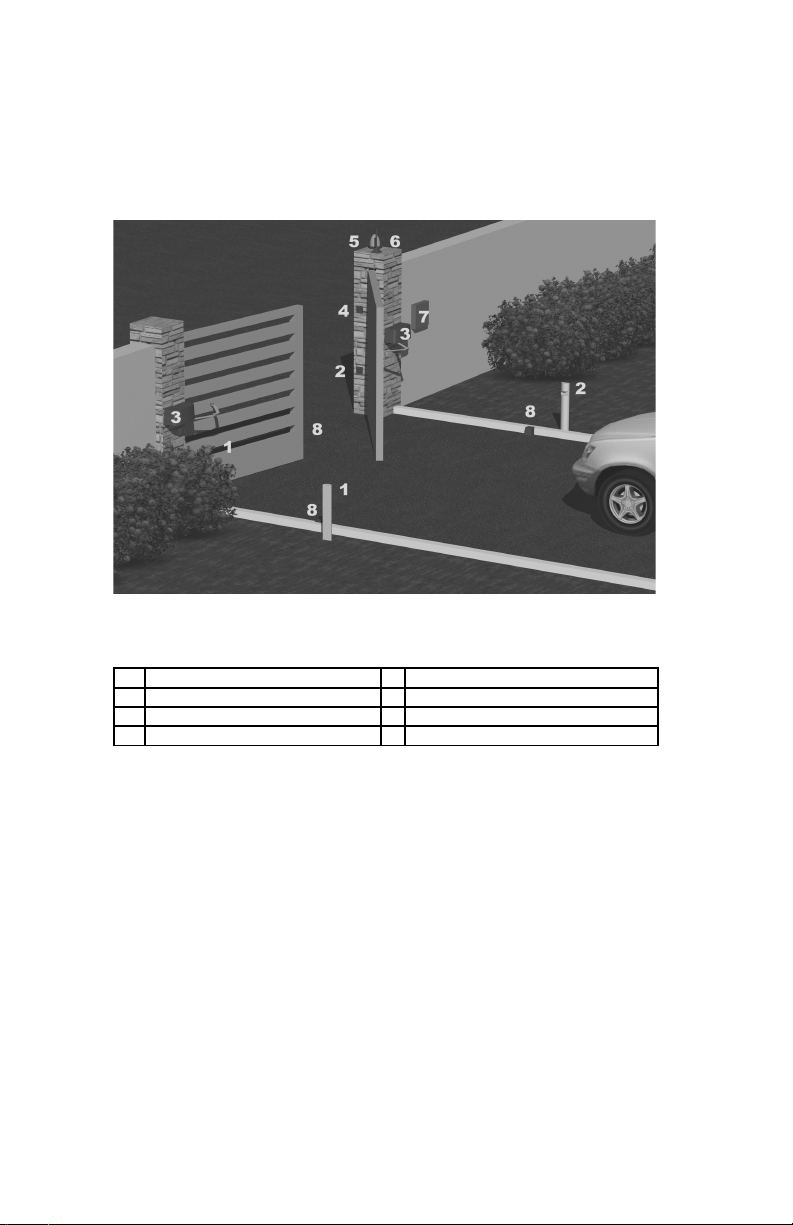

EQUIPMENT

In order to install the automation you have to provide yourself with

keys, screwdriver, metre, slope detector (water level), saw, drilling

machine and welding machine.