INSTALLATION MANUAL

Our compliments for your excellent choice. The GR6-8 electro-

mechanical gear motor has been produced for reliability and high quality.

This Manual will offer information you may need to install your gear motor

assuring long-lasting performance and to safeguard your safety.

HOWEVER CAUTION IS UNQUESTIONABLY INDISPENSABLE AND

NOTHING IS BETTER THAN PREVENTING ACCIDENTS. GR products

have been made to conform with rules and laws in force at time of

manufacture.

This manual is designed exclusively for the specialized installation

expert in the criteria of construction and equipment to assist in the

protection against accidents in the installation and use of the gate; door

and automation of such gates (adhere to the rules and laws in force).

On completion the installer should issue to the end consumer an

instruction manual according to EN 12635.

Before proceeding with the installation the installer must provide an

analysis of the identification and management of risks as per the

standards EN 12453 and EN 12445.

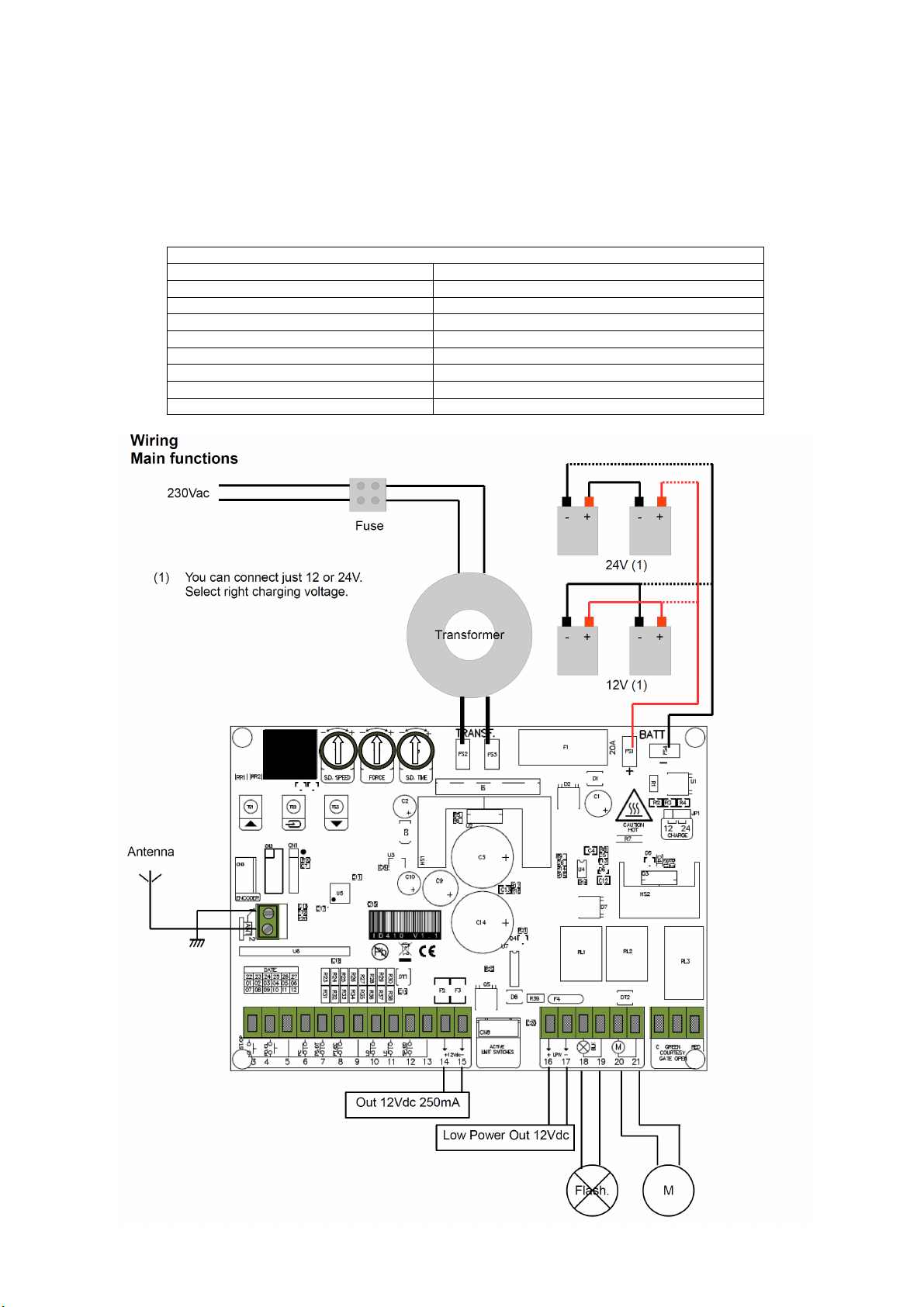

All wiring of the various external electrical components connected to

the automation (e.g. Photocells, flashing lights, keypads etc) must be

carried out according to EN 60204-1 and the amendments made of the

point 5.2.2 of EN 12453.

It is prohibited to do any repair or adjustment of the equipment if you

have not taken all necessary precautions to avoid possible accidents

(example: power supply disconnected, engine block). All mechanisms in

motion must be equipped with appropriate protections.

The mains power line must be protected for maximum current in

locked rotor condition as per government electrical laws.

Install the gear motor on gates that conform to EN 12604.

Perform the measure of strength developed by the gear motor and

take the appropriate steps as per EN 12445.

Positioning photocells: These safety devices must be installed at a

height not exceeding 70cm from the ground and at a distance from the

floor movement of the door of no more than 20cm. Their proper

functioning of the photocells must be verified at the end of installation

according to Section 7.2.1 of EN12445.

Keep the activation controls of automation out of reach of children.

The controls should be installed at a minimum 1.5m height above the

ground and outside the range of actions of moving parts such as the

gate.

All activation actions must be executed only at points from where

the automation is fully visible.

Operate the remote only in view of automation.

Store carefully this manual in a suitable place known to all

interested people.

Any unauthorized and arbitrary modification made to this product,

releases the company GR SISTEMI AUTOMATICI DI APERTURA Srl

and from any liability resulting from damage or injury to things, people or

animals.

The non-observance of regulations and of safety standards here

listed releases the company GR SISTEMI AUTOMATICI DI APERTURA

Srl from any liability resulting from damage or injury to things, people or

animals.

The automation must be coupled to a control board equipped with

torque regulation that provides an anti crushing safety as described in EN

12453 - EN 12445

CONFORMITY DECLARATION:

It’s in accordance with Machine Directive 39/89/CE and following modify.

It’s in accordance with the following directive CE:

Electromagnetic compatibility Directive 89/336/CEE and following modify.

Low tension Directive 73/23/CEE and following modify.

Have been applied the following harmonized norms:

EN292/1/2, EN 294, EN60335-1, UNI EN 12453, and what applicable of

the EN12445-2000.

Castiglione d/St. 05-10-2020

DISMANTLING / REINSTALLING

This product falls within the scope of the Directive 2012/19 / EU

concerning the management of waste electrical and electronic equipment

(WEEE). The appliance must not be disposed of with domestic waste as

it is made of different materials that can be recycled at the appropriate

facilities. Inquire through the municipal authority regarding the location of

the ecological platforms to receive the product for disposal and its

subsequent correct recycling. Furthermore, it should be remembered

that, upon purchase of an equivalent appliance, the distributor is obliged

to collect the product for disposal free of charge. The product is not

potentially dangerous for human health and the environment, not

containing harmful substances, but if abandoned in the environment

negatively impacts on the ecosystem. Read the instructions carefully

before using the appliance for the first time. It is recommended that you

do not use the product for any purpose other than that for which it was

intended, there being a danger of electric shock if used improperly.

The crossed-out bin symbol, on the label on the appliance,

indicates the compliance of this product with the

regulations regarding waste electrical and electronic

equipment. Abandonment in the environment of the

equipment or illegal disposal of the equipment is

punishable by law.

To dismantle or reinstall the automation elsewhere, you need to:

1 - Disconnect the power supply and disconnect the electrical system.

2 - Remove the control panel and all the components of the installation.

In the event that some components are damaged or unable to be

removed, replace them.

SAFETY RULES

During the installation and the use of the automation, pay attention to the

following safety rules:

Distance security!

Mechanisms moving!

Do not install automation in an environment saturated with explosive

mixtures!

Electric Shock!

Use gloves!

Use welding glasses!

Maintain ear protection!

USE OF THE AUTOMATION

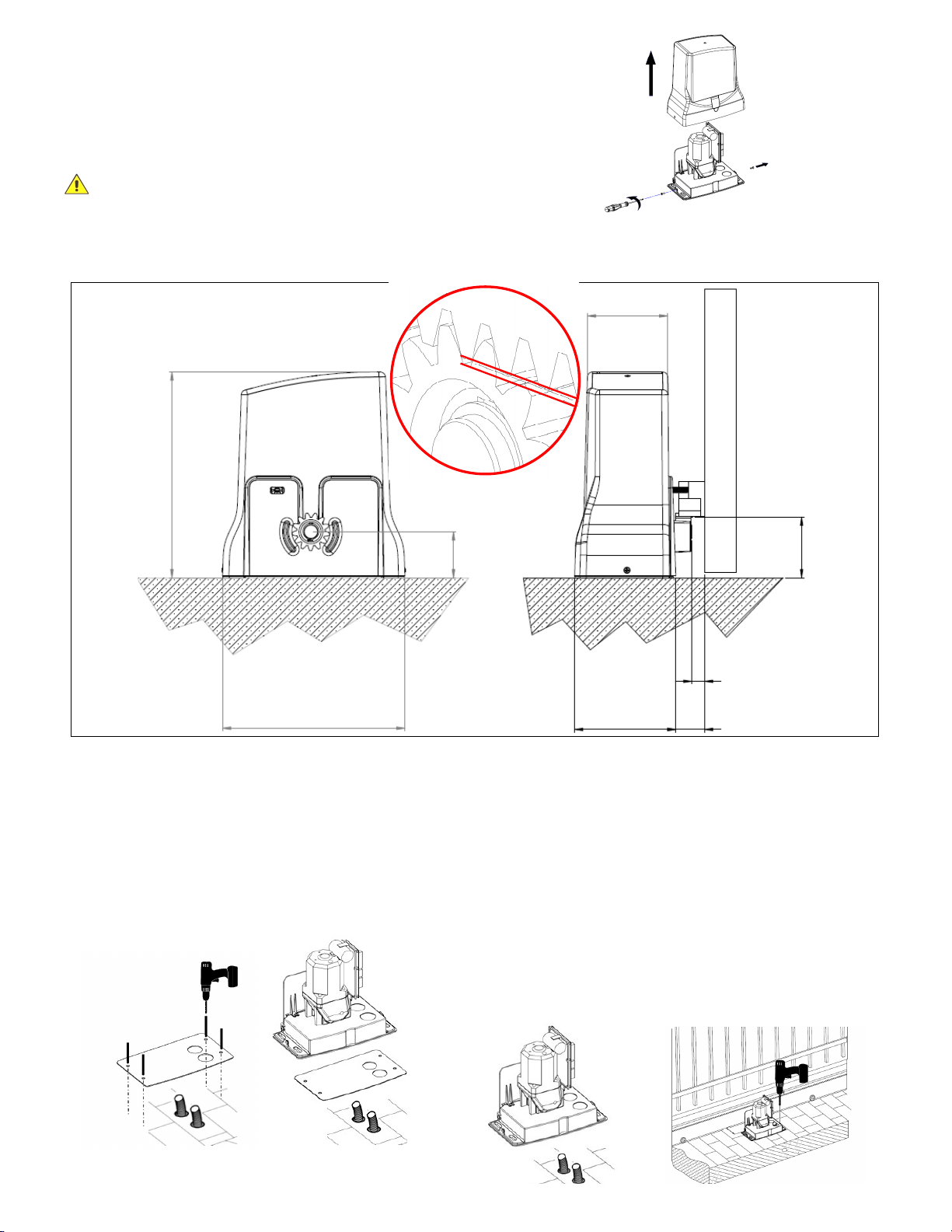

The gearmotor GR6-8 was designed and built for the opening of gates

with weight max. 800kg. G.R. Srl assumes no responsibility for a

purpose other than that provided by gearmotor GR6-8. Since automation

can be put into motion in view by button or remotely by remote control, it

is essential to check frequently the perfect efficiency of all safety devices.

It is advisable to check periodically (every six months) the regulation of

electronic friction of which must be equipped the electronic control board.

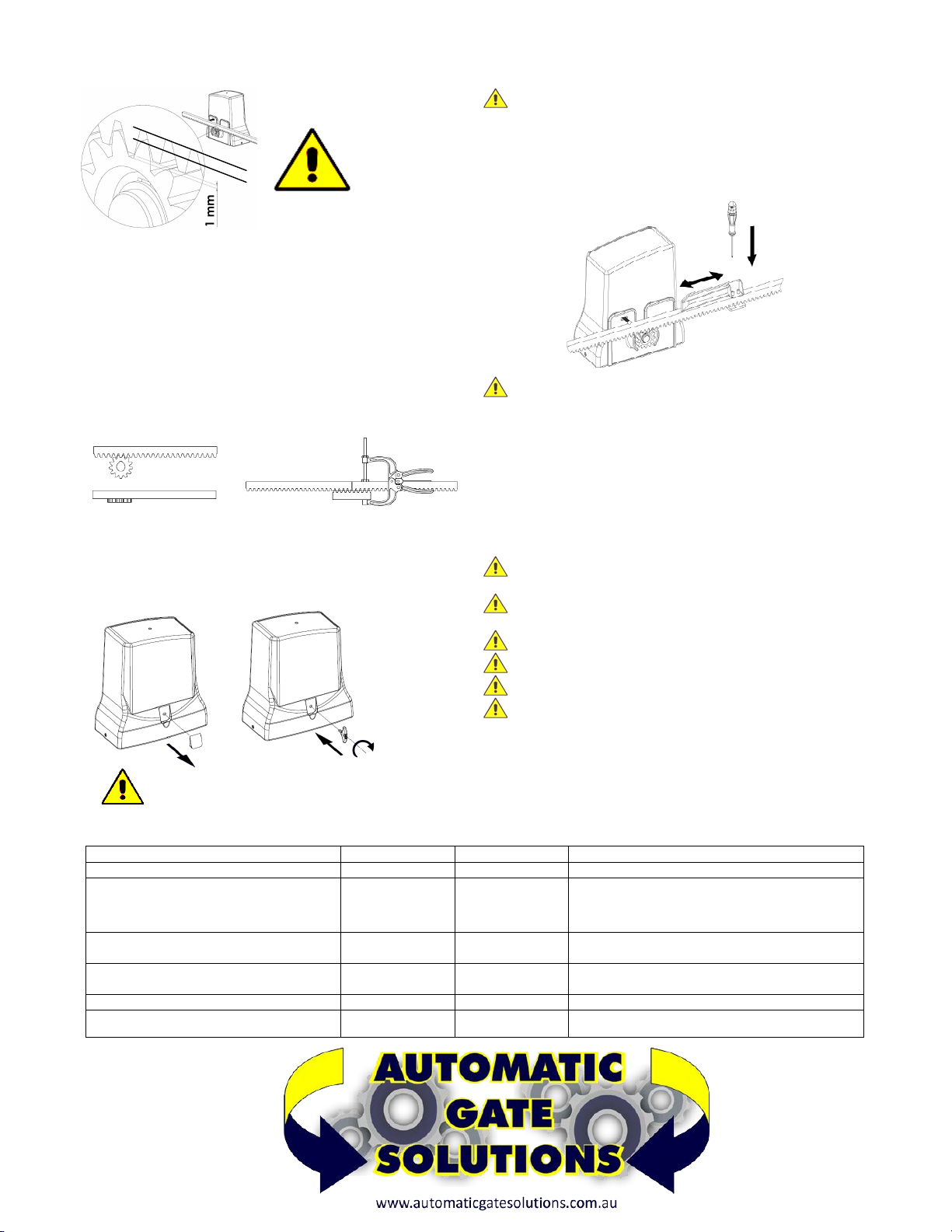

TECHNICAL DATA

GR6 12V GR8 12V

600Kg 800Kg

12Vdc 12Vdc

190W 350W

2.6A 2,5A

1400 1400

13,4Nm 21,2Nm

10,2m/min 10,2m/min

150°C 150°C

-20°C +60°C -20°C +60°C

GREASE GREASE

IP44 IP44

65% 65%