Setup

GeneralInformationPressureReliefProcedure

NOTE:

Reference numbers and lettersin parentheses

inthe text referto the callouts in the figures and the

parts drawing.

NOTE:

Always use Genuine Graco Parts and Acces-

sories, available from your Graco distributor.

Grounding

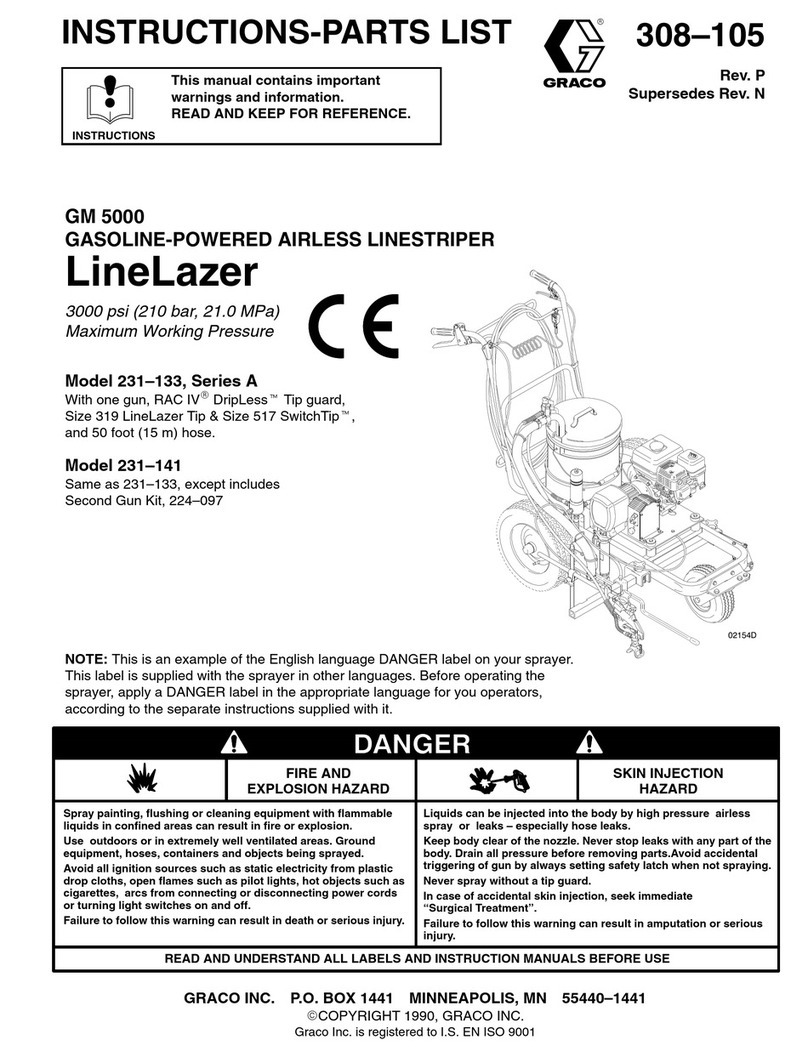

FIRE AND EXPLOSION HAZARD

system as explained below. Also read

Beforeoperating,thepump, ground the

the section

FIRE

OR

EXPLOSION

HAZ-

ARD

on page

6.

1

2.

3.

4.

5.

6.

7.

Sprayer: make sure the grounding chain

(106)

contacts the ground while the unit is moving. See

page

46.

For stationary spraying, connect a

ground wire and clamp

(159)

to a true earth

ground.

maximum of

500

ft.

(150

m) combined hose

fluid

hoses: use only grounded hoses with a

length to ensure grounding continuity.

Spray

gun:

obtain grounding through connection to

a properly grounded fluid hose andsprayer.

Objectbeingsprayed: according to local code.

Fluidsupply

container:follow your local code.

code. Use only metal pails, which are conductive,

Solventpails usedwhen flushing: follow your local

pailona nonconductive surface, such as paper or

placed on

a

grounded surface. Do not place the

cardboard, which interrupts the grounding continu-

ity.

To

maintaingrounding

wntinuify

when flushing

or

gun firmlyto the sideof a groundedmetalpail,

relieving pressure, hold

a

metal partof the spray

then triggerthe gun.

INJECTION HAZARD

Fluidunder high pressure can be in-

jected through the skin and cause seri-

ous

injury.

To

reduce the risk of an injury

from injection, splashing fluid, or moving parts, fol-

I

low the

Pressure

Relief

Procedure

whenever you:

are instructed to relieve the pressure,

stopspraying,

check or service any ofthe system equipment,

or install or clean the spray tips.

1.

Engage the spray gun safety latch.

2.

Turn the ON/OFF switchto OFF.

3.

Fiip the pressure control switch to OFF.

4.

Disengage the gunsafetylatch. Hold a metal part

of the gun firmlyto the sideof a grounded metal

pail, and triggerthe gun to relieve pressure.

5.

Engagethegunsafetylatch.

6.

Hold the pressure relief tube firmly to the sideof a

valve. Leave the valve openuntilyou are readyto

grounded metal pail, and open the pressure relief

spray again.

system from starting unexpectedly.

7.

Disconnect the sparkplugcable to prevent the

clogged, orthatpressure has not been

fully

relieved

If

yoususpect that thespraytip or hose

is

complete/y

tip guard retaining nut or hose end coupling and relieve

afterfollowing thestepsabove,

very

s/ow/y

loosen the

pressure gradually, then loosen completely. Now clear

the tip or hose.

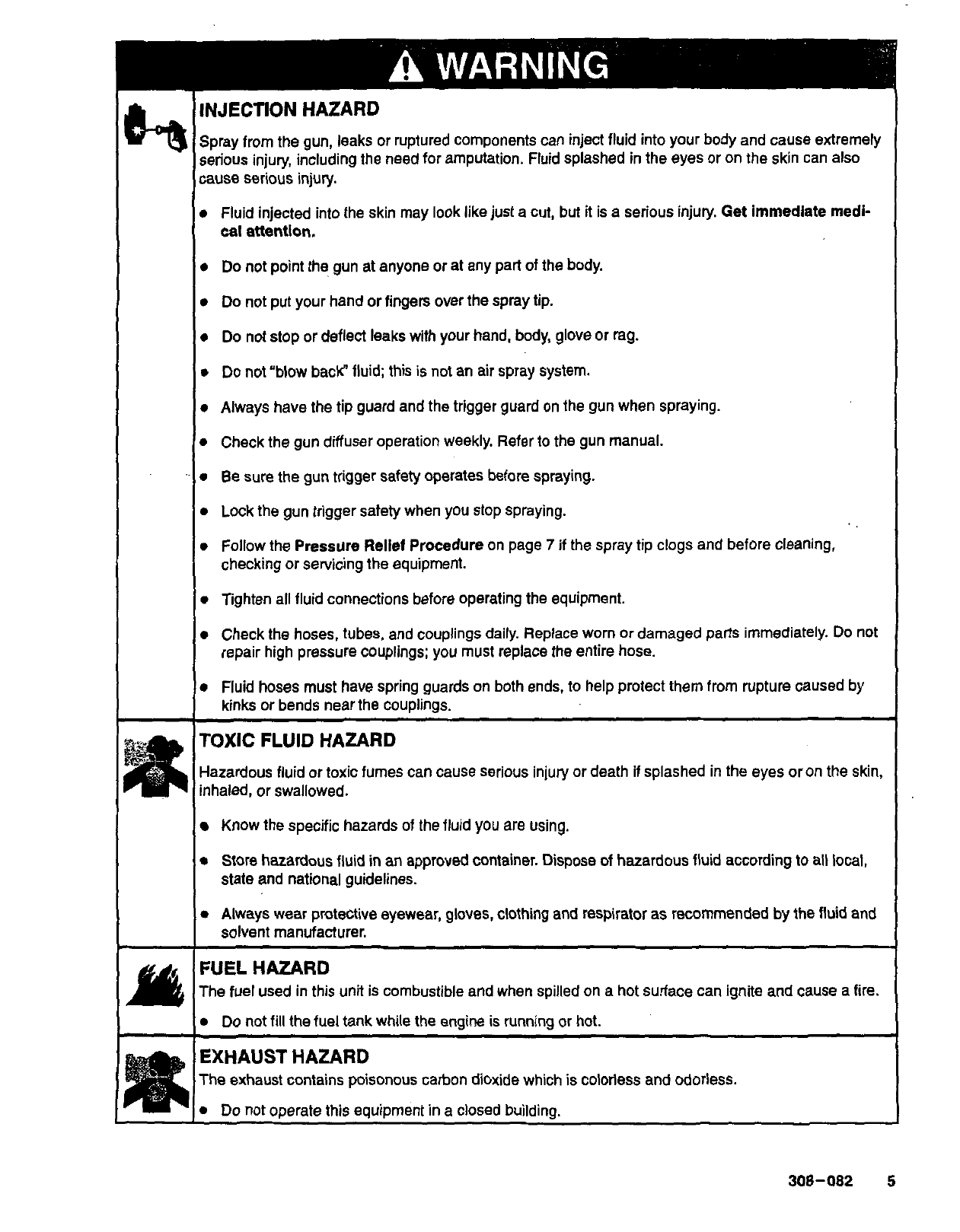

Valve shownIn Valve shown

CLOSED

position.

in OPEN position.

-

Fig.

2

308-082

7