Installation

4308950C

Installation

Installing the Lubrication Controller

1. Select a flat surface upon which to install the Lubri-

cation Controller, and drill mounting holes according

to the Mounting Hole Layout on page 10.

2. Remove Lubrication Controller cover, and secure

the junction box using four #6 screws (not provided).

3. Connect solenoid valve leads to terminals 4(-) and

6(+) (output).

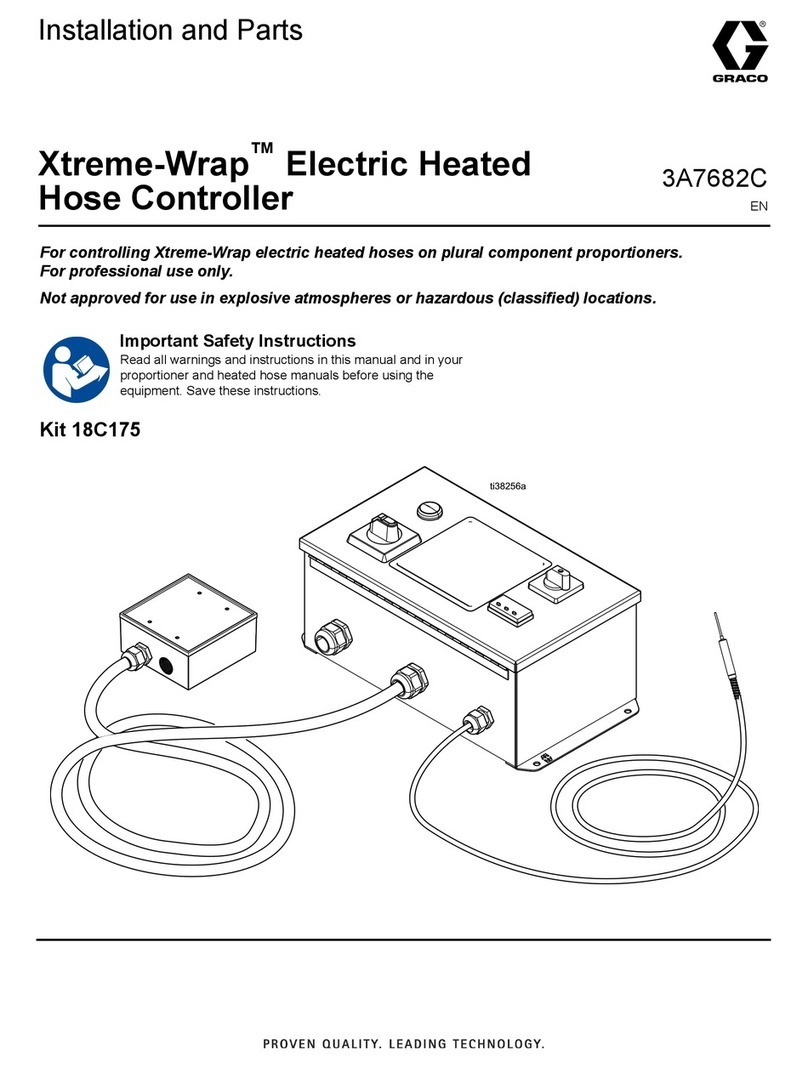

4. Fig. 2. Step optional for use of external alarm.

Terminals 7 and 8 are a normally open, voltage–free

switch, available as a switching device for an exter-

nal alarm circuit. Connect fused (+) power supply

(not supplied) to terminal 8. Connect terminal 7 to

external alarm. Ground external alarm to complete

circuit.

5. This step is optional.

Connect terminals 9 and 11 to a normally–open

pressure switch installed in system lubricant supply

line for pressure–controlled system shutdown.

NOTE: The pressure switch, upon detecting the pre-

set pressure, will send a signal to the Lubrication

Controller to deactivate the air solenoid valve, which

will deactivate the pump.

6. This step is optional.

Connect terminals 12 and 13 to a normally–open

low–level switch (user provided).

NOTE: Upon detection by a low–level sensor, the

Lubrication Controller will activate the alarm condi-

tion.

7. This step is optional

Connect terminals 14 and 15 to a normally open

switch. Closing of the switch will suspend Lubrica-

tion Controller operation. Reopening of the switch

will resume Lubrication Controller function from the

point at which operation was suspended.

8. Connect the power leads from an isolated power

supply. Connect terminal 3 to the negative (-) lead

(ground), and connect terminal 2 to the positive (+)

lead.

9. Replace the Lubrication Controller cover.

CAUTION

This Lubrication Controller is not designed to be

operated in a caustic environment

CAUTION

Use only the pre-drilled holes under the cover fas-

teners to mount the timer. Failure to use the desig-

nated mounting holes could cause circuit board

damage.

CAUTION

Do not ground any lead for the pressure switch or

the low level switch. Circuit board damage may

result.

FIG. 2_______________________________________

8855A

24V

max.

Light

1-amp Fuse

External

Alarm Device

24V 1 amp. max.

CAUTION

If using the low level indication feature, the lubrica-

tion controller will remain in alarm mode and will not

function until the low level switch is opened by refill-

ing the fluid reservoir. Failure to correct the low level

condition will result in interruption of the automatic

lube system which could lead to premature bearing

failure.

AUTOMATIC SYSTEM ACTIVATION

Do not connect power to timer if the pump power

supply is on, unless activation of the automatic lubri-

cation system is intended. This device is an auto-

matic timing device that activates the output circuit

(air solenoid valve) upon power connection or upon

exit of the programming function. Ignoring this warn-

ing could lead to serious injury including fluid injec-

tion and amputation due to activation of connected

system components.