SAFETY

W

ARNINGS

SERIOUS BODILY INJURY, EXPLOSION, FIRE, OR ELECTRIC SHOCK

CAN OCCUR IF THE PRECAUTIONS BELOW ARE NOT FOLLOWED.

ELECTRICAL EQUIPMENT SHALL ONLY BE INSTALLED, OPERATED, AND SERVICED BY

TRAINED, QUALIFIED PERSONNEL WHO SHALL BE FULLY CONVERSANT WITH THE

REQUIREMENTS STATED WITHIN THIS INSTRUCTION MANUAL.

READ AND UNDERSTAND ALL INSTRUCTION MANUALS AND

WARNING LABELS BEFORE OPERATING THE EQUIPMENT.

FIRE, EXPLOSION, OR ELECTRIC SHOCK HAZARD

General

Safety

To

reduce the risk of fire, explosion, or electric shock:

1. DO

NOT operate in hazardous locations, as defined in Article 500 of

the

National Electrical Code (USA).

2.

Operate the PrecisionMix in well–ventilated areas only

.

3.

The equipment MUST be grounded (see below).

4.

Keep liquids away from the electrical components.

5. Disconnect

electrical power at the main switch before servicing

the

unit.

6. DO

NOT disassemble the electrical

control. Call a qualified electri

-

cian.

Grounding

All

parts of the fluid

system must be properly grounded to reduce the risk

of

static electricity discharge. Static electricity is created by the high ve

-

locity

flow of fluid through the system. When the static electricity is

dis

-

charged,

sparking occurs. Sparks can ignite fumes from solvents and the

fluid being sprayed, dust particles and other flammable substances,

whether

you are spraying indoors or outdoors, and can cause a fire or ex

-

plosion

and serious bodily injury and property damage.

In

a low

pressure air spray system, static sparking is generally not a prob

-

lem.

However

, some simple precautions should be taken to reduce the

risk.

CHECK your

local electrical code for detailed grounding instructions

for

your area and

type of equipment, and BE SURE to ground all of this

spray

equipment:

1.

PrecisionMix:

the PrecisionMix electronics must be grounded

through an approved grounded power cord, connected to a

grounded

electrical socket. T

o ground the PrecisionMix frame, use

a ground wire and clamp connected to a true earth ground. See

page

33 for an available ground wire and clamp.

2.

Feed

pumps or

pressure pots:

use a ground wire and clamp. See

your

separate pump or pressure pot manual.

3.

Air compressor:

follow manufacturer

’

s recommendations.

4.

Object being sprayed:

according to your local code.

5.

All

solvent pails used when flushing,

according to your local

code.

Use only metal pails, which are conductive, placed on a grounded

surface.

Do not place the pail on a nonconductive

surface, such as

paper

or cardboard, which interrupts the grounding continuity

.

6.

T

o maintain grounding continuity when flushing

or relieving pres

-

sure

,

always hold a metal part of the spray gun firmly to the side of a

grounded

metal

pail, then trigger the gun.

Flushing

Safety

Before

flushing,

be sure the

entire system and flushing pails are properly

grounded. Refer to Grounding, at left. Follow the Pressure Relief

Procedure below

. Always use the lowest possible fluid pressure, and

maintain

firm metal–to–metal contact between the gun and the pail during

flushing

to reduce the risk of

injury from fluid splashing or static sparking.

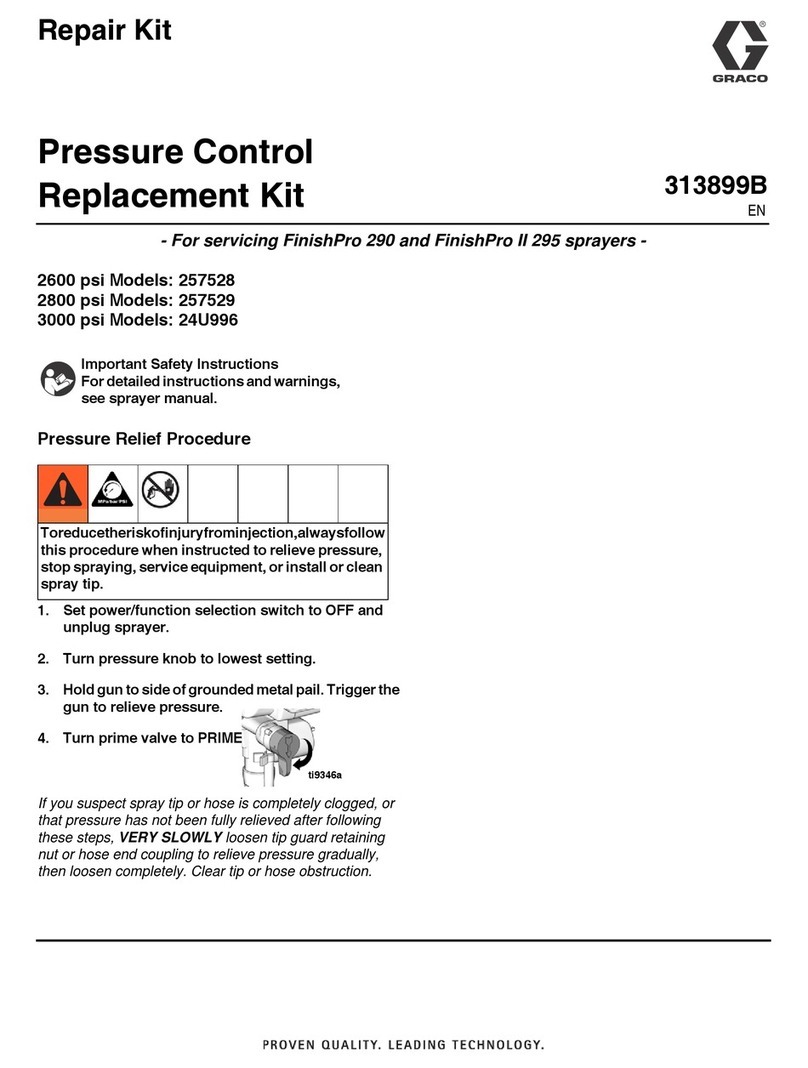

Pressure

Relief Procedure

To

reduce the risk of serious bodily injury

, including splashing fluid

in

the eyes or on the skin, always follow this procedure whenever

you

shut of

f the PrecisionMix, when checking or servicing any part

of the system, when

installing, cleaning, or changing fluid tips, and

whenever

you stop spraying.

1. Press

the ST

OP switch on the PrecisionMix control panel at

the

beginning of the catalyst (component B) dispense.

2. Relieve

fluid and air pressure at the component and solvent

feed pumps or pressure pots, as explained in their separate

instruction

manuals.

3.

Press the ST

AR

T switch on the PrecisionMix control panel.

4. Hold a metal part of the spray gun firmly to the side of a

grounded

metal pail, and trigger the gun to relieve fluid pres

-

sure.

5. Set

the ON/OFF switch on the control panel to OFF

,

resetting

the

machine control counters.

6.

Set the ON/OFF switch to ON. Press the ST

AR

T switch.

7. Hold a metal part of the spray gun firmly to the side of a

grounded

metal pail, and trigger the gun to relieve fluid pres

-

sure

in the component A fluid section.

If

you suspect that the fluid tip or hose is completely clogged, or

that

pressure has not been fully relieved after following the steps

above,

VER

Y SLOWL

Y loosen the hose end

coupling and relieve

pressure

gradually

, then loosen completely

. Now clear the tip

or

hose.

EQUIPMENT MISUSE HAZARD

General

Safety

Any misuse of the spray equipment or accessories, such as

overpressurizing,

modifying parts, using incompatible chemicals and flu

-

ids, or using worn or damaged parts, can cause them to rupture and result

in

serious bodily injury

, such as splashing fluid in the eyes or on the skin,

or

fire, explosion or property damage.

NEVER

alter or modify any part of this equipment; doing so

could cause it

to

malfunction.

CHECK

all spray equipment regularly and repair or replace worn or dam

-

aged

parts immediately

.

Always

wear protective eyewear

, gloves, clothing and

respirator as rec

-

ommended

by the fluid and solvent manufacturer

.

System

Pressure

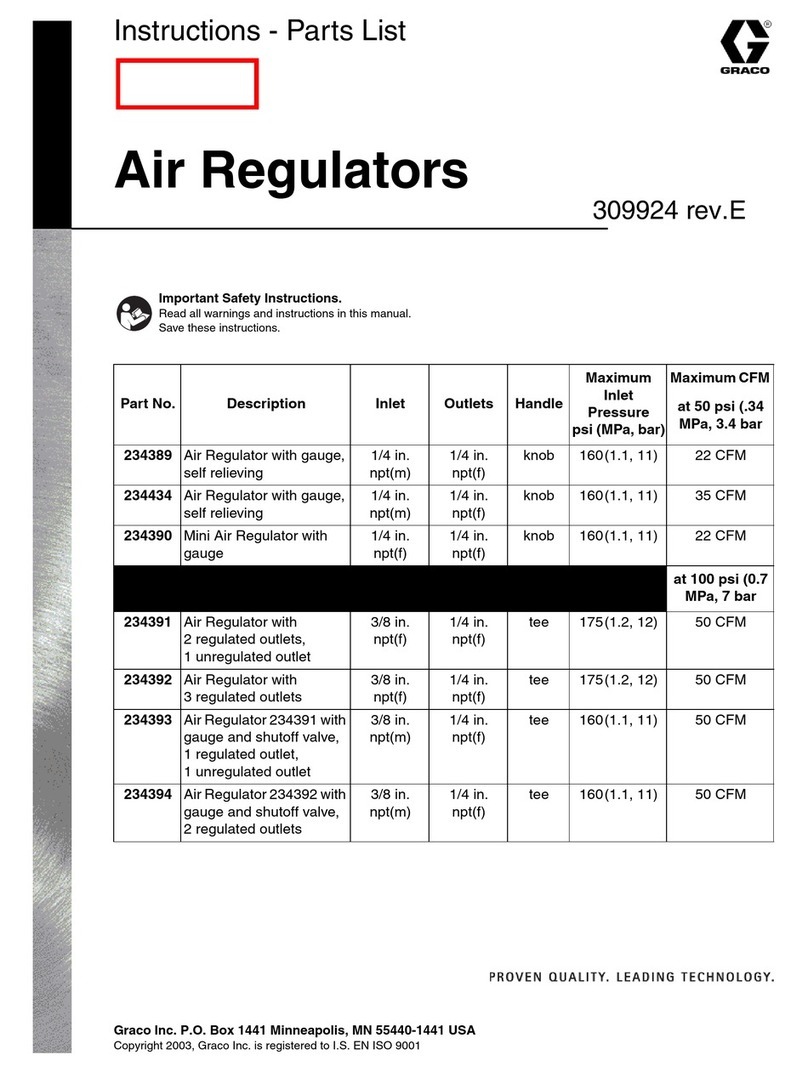

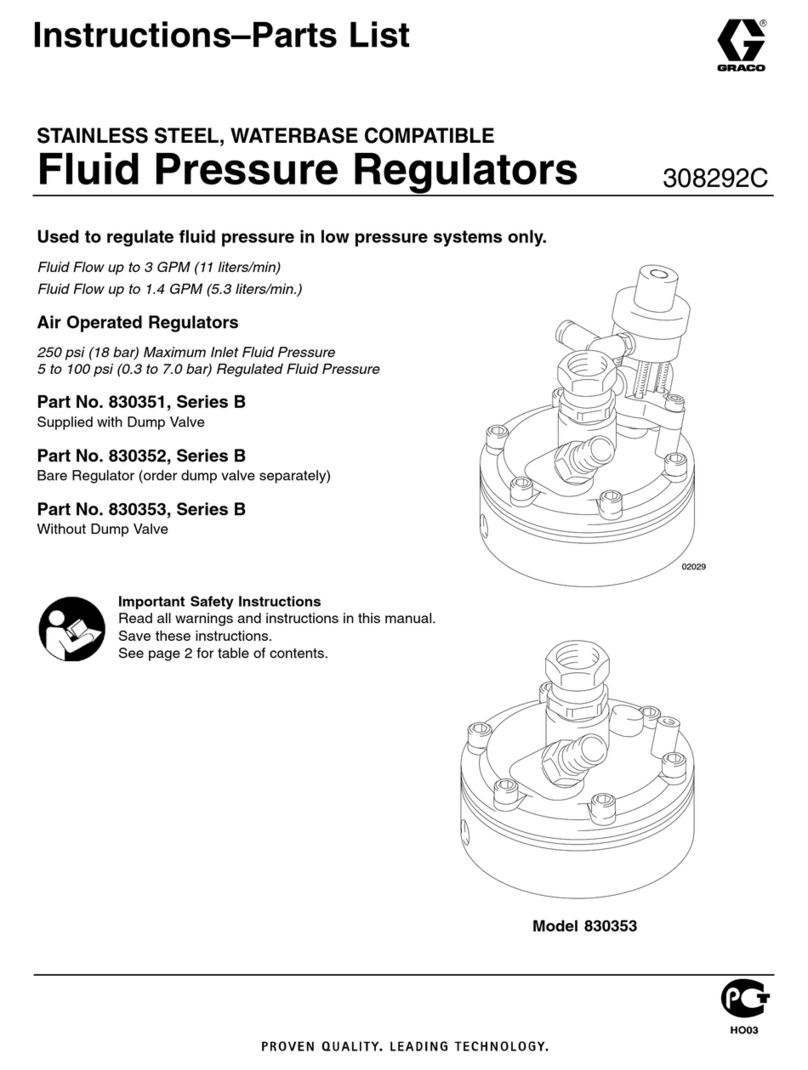

NEVER exceed 100 psi (7 bar) air pressure to the PrecisionMix, and

NEVER

exceed 120 psi (8.4 bar) maximum fluid working pressure.

Be

sure that all spray equipment and

accessories are rated to withstand

the

maximum air and fluid working pressures of the system. DO NOT ex

-

ceed the maximum working pressure of any component or accessory

used

in the system.

Fluid

Compatibility

BE

SURE that all fluids and solvents used are chemically compatible with

the

wetted parts of each of your system’

s components. Always read

the

manufacturer’s

literature before using fluid or solvent in your system.

IMPORTANT

United

States Government safety standards have been adopted under the Occupational Safety and Health Act. These standards – particularly the Gen

-

eral

Standards, Part 1910, and the Construction Standards, Part 1926 – should be consulted.