Component Identification

4313855K

Icon Definitions

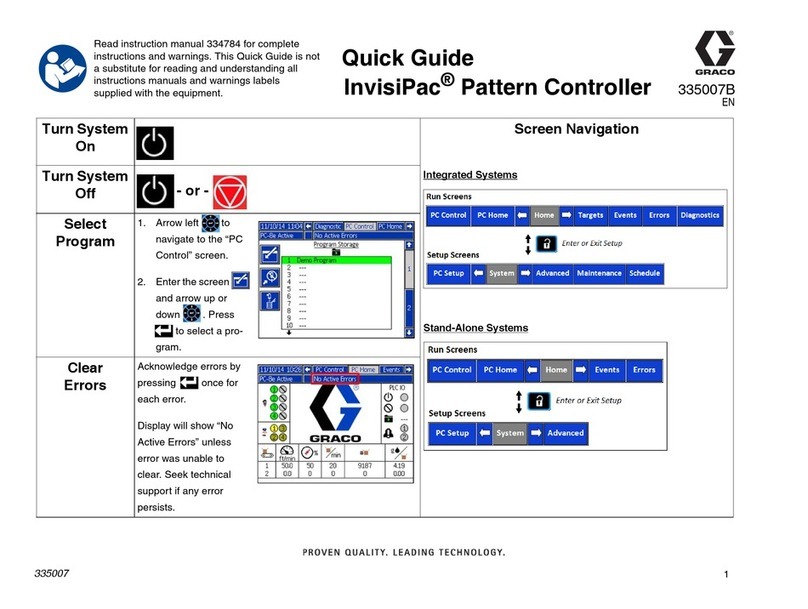

The following icons are used throughout this instruction manual and on the Controller’s Run and Setup Screens.

Refer to this table if you are unsure of an Icon’s meaning.

*See Field E, page 3 for location of these Function Icons.

Power on indicator*. When power is supplied to the Lubrication Controller, Green LED illuminates under Function Icon

located above display screen.

Pump On indicator*. When Pump On is running, Yellow LED illuminates under Function Icon located above display

screen. Icon also is displayed on top left side of Prelube Run screens (see page 37).

Pump Off indicator. When Pump Off is running, icon is displayed on top left side of Run screens (see page 38).

Alarm event activated. LED illuminates when an Alarm event occurs. Icon also displays on top right side of Alarm

screen (see page 40).

Brightness adjustment. Use the LEFT/RIGHT Arrow key to adjust display backlight (brighter or darker) (see page 20).

Contrast adjustment. Use the UP/DOWN Arrow key to adjust screen contrast (see page 20).

Low Level Alarm. Icon appears on display screen. Indicates the lubrication fluid level is low.

Change Icon. When icon appears on PIN setup screen, indicates changes can be made to PIN number or new PIN

number can be added.

Lock Icon. Indicates the Setup screens are password protected and require the user to provide the correct PIN number

to access this feature.

Setup mode active. When user is on the Main Setup Screen in the Setup Mode, icon displays on the upper right corner

of the display screen.

Timer mode activated. Displays on right side of screen when a Timer Setup or Run screen is displayed (pages 24, 27,

37 and 38).

Pressure mode activated. Icon displays on right side screen when a Pressure Setup or Run screen is displayed (page

25 and 37).

Pressure mode error. Icon displays on alarm screen to signal the allotted time ran out before the pressure switch was

tripped.

Cycle count mode active*. Yellow LED illuminates under Function Icon located above display screen. Icon also appears

on right side of display screen when a Cycle Setup or Run screen is displayed (page 25 and 38).

Machine count active. Displays on right side of Setup or Run screen when a Machine Count screen is displayed (page

27 and 39).

Machine count error. When icon displays on alarm screen, indicates the set number of machine counts was not

received before time expired (page 39). This would trigger an alarm event.

Cycle switch input error. Icon displays in center of Alarm screen to indicate the allotted time ran out before the

programmed number of cycle switch activations was received (see Alarm Screen, page 40).

Alarm*. Red LED illuminates under symbol located above display screen. Icon also appears on display when no valid

run values have been entered.