Contents

Related Manuals ................................................ 3

Models............................................................... 3

Approved System Components ........................... 3

arnings ........................................................... 4

Introduction........................................................ 6

Controller Features and Options.......................... 6

Installation Options ............................................. 6

Interlocks..................................................... 7

No Integration.............................................. 9

Basic Integration.......................................... 10

PLC Integration............................................ 11

Pre-Installation Steps.......................................... 12

Ventilate the Spray Booth.............................12

Install the Pro Xpc Auto Spray Gun ............... 12

Interlock aterborne Isolation

Enclosure....................................... 12

Mount the Controller ........................................... 13

Location ...................................................... 13

Mounting ..................................................... 13

Grounding ................................................... 14

Controller Connections........................................ 15

Overview..................................................... 15

Connections ................................................ 16

Discrete I/O........................................................ 18

Isolation ...................................................... 18

I/O Grounding.............................................. 18

REMOTE Input Operation............................. 18

REMOTE Output Operation.......................... 18

Signals........................................................ 19

Analog Inputs .............................................. 23

Analog Outputs............................................ 23

Digital Inputs................................................ 24

Digital Outputs............................................. 24

Timing Diagrams.......................................... 24

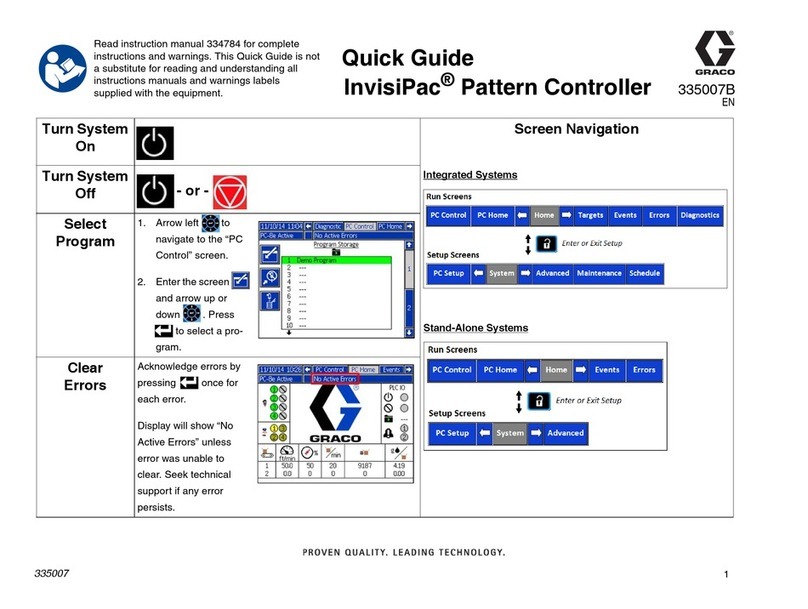

Controller Display and Features........................... 30

Screen Areas............................................... 30

Icons........................................................... 30

Input Keys and Switches .............................. 31

Additional Features ...................................... 31

Setup................................................................. 33

Setup Screen 0............................................ 35

Setup Screen 1............................................ 35

Setup Screen 2............................................ 36

Setup Screen 3............................................ 36

Setup Screen 4............................................ 37

Setup Screen 5............................................ 37

Setup Screen 6............................................ 37

Setup Screen 7............................................ 37

Setup Screen 8............................................ 38

Setup Screen 9............................................ 38

Setup Screen 10.......................................... 39

Setup Screen 11.......................................... 39

Operation........................................................... 40

System Start-up........................................... 40

Run Screen 1 ..............................................40

Run Screen 2 ..............................................41

Run Screen 3 ..............................................42

Arc Detection............................................... 43

Screen Map........................................................ 45

Error Code Troubleshooting ................................ 48

Repair................................................................ 51

Main Circuit Board or Keypad Membrane

Removal ........................................ 51

Power Board Removal ................................. 53

Software Update.......................................... 54

Parts.................................................................. 55

Dimensions........................................................ 56

Technical Data ................................................... 59

Graco Standard arranty.................................... 60

2333266D