Graco 24N468 User manual

Other Graco Controllers manuals

Graco

Graco 15J753 User manual

Graco

Graco Trabon LC-1000 User manual

Graco

Graco G Series Operation manual

Graco

Graco 238889 Operation manual

Graco

Graco ProMix 2KS Operating instructions

Graco

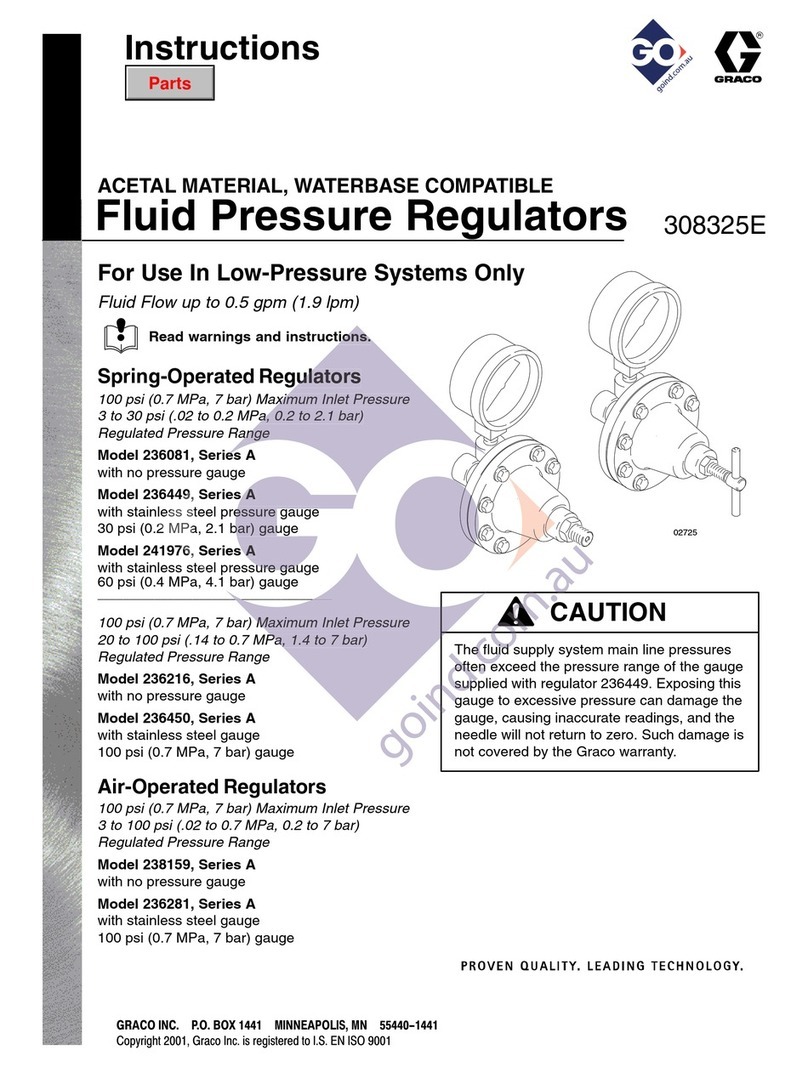

Graco Series A User manual

Graco

Graco IPH-25 Series Guide

Graco

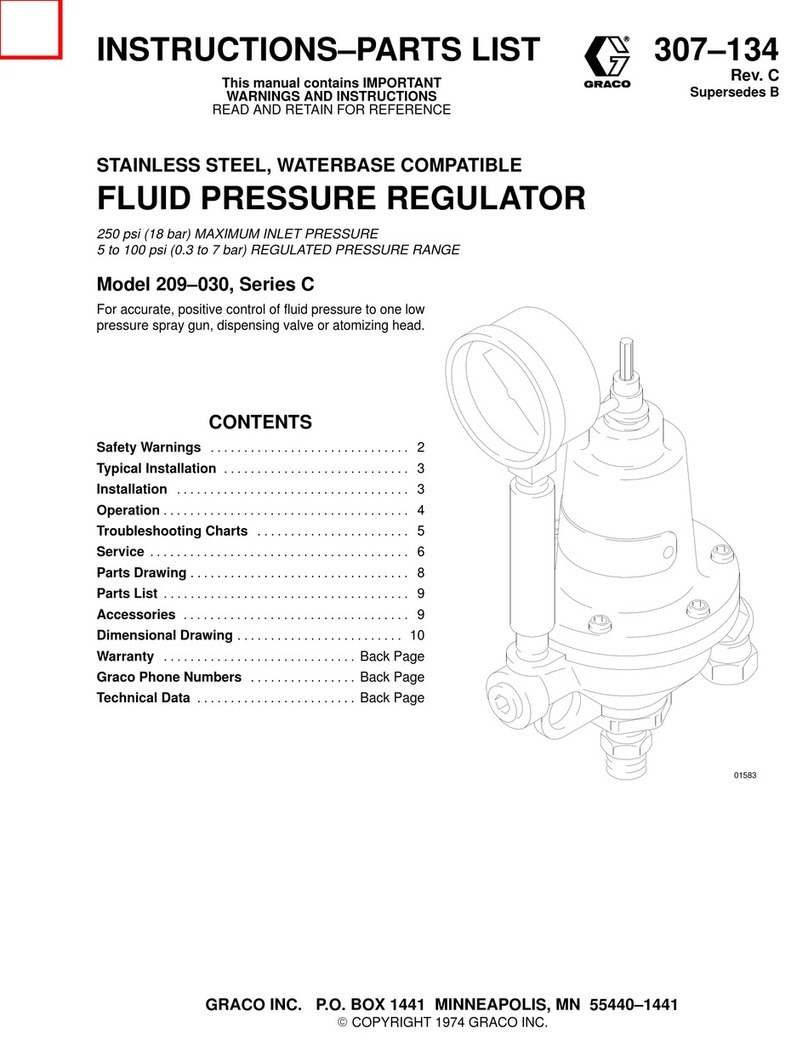

Graco Series B Operation manual

Graco

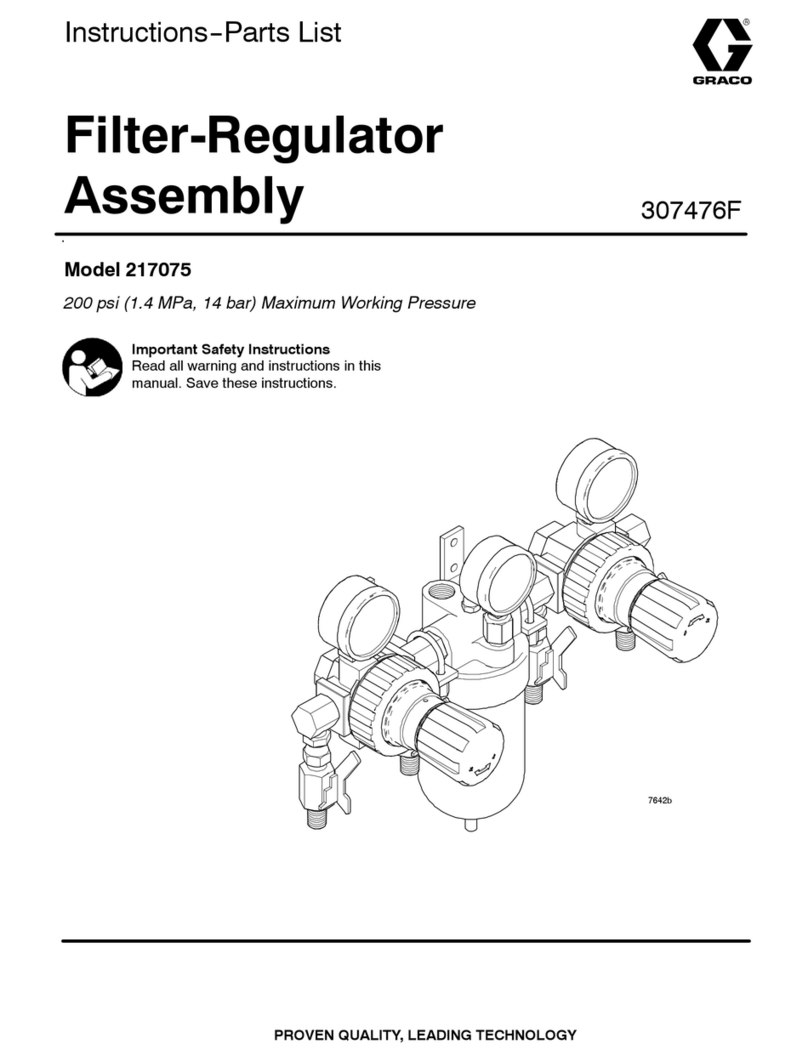

Graco 217075 Operation manual

Graco

Graco ProControl 1KS Instruction Manual

Graco

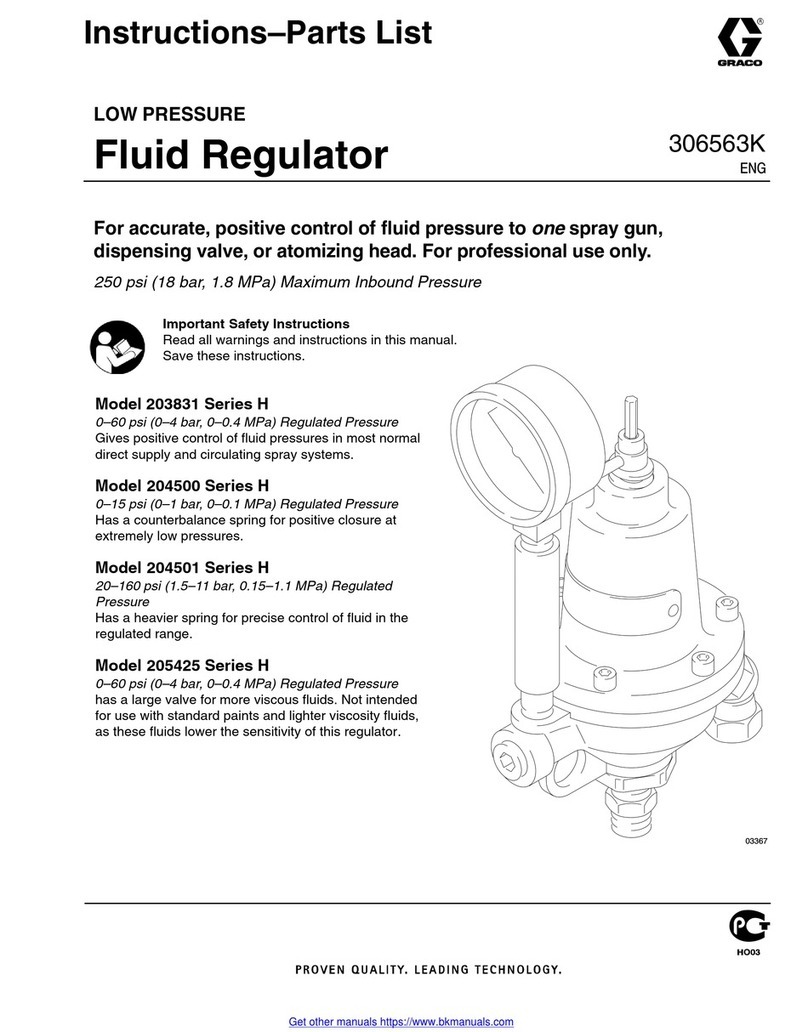

Graco H Series Operation manual

Graco

Graco Pro Xpc 24Y307 User manual

Graco

Graco 115123 Datasheet

Graco

Graco SERIES F Operation manual

Graco

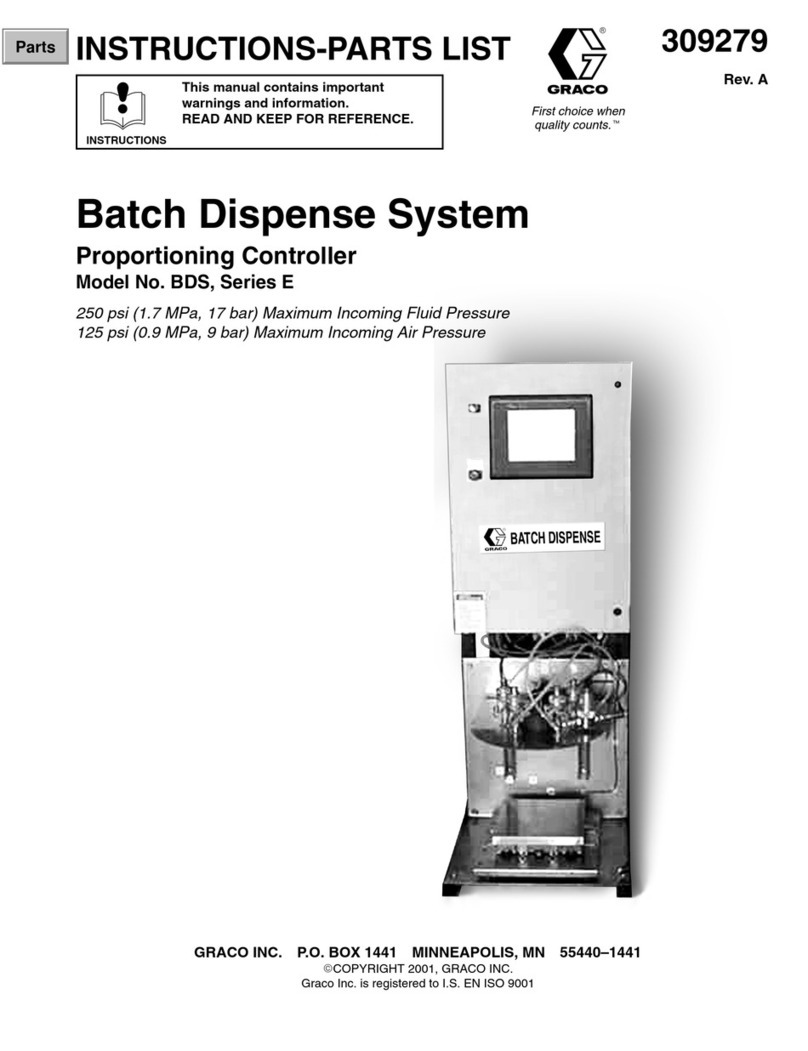

Graco BDS Operation manual

Graco

Graco 24W482 User manual

Graco

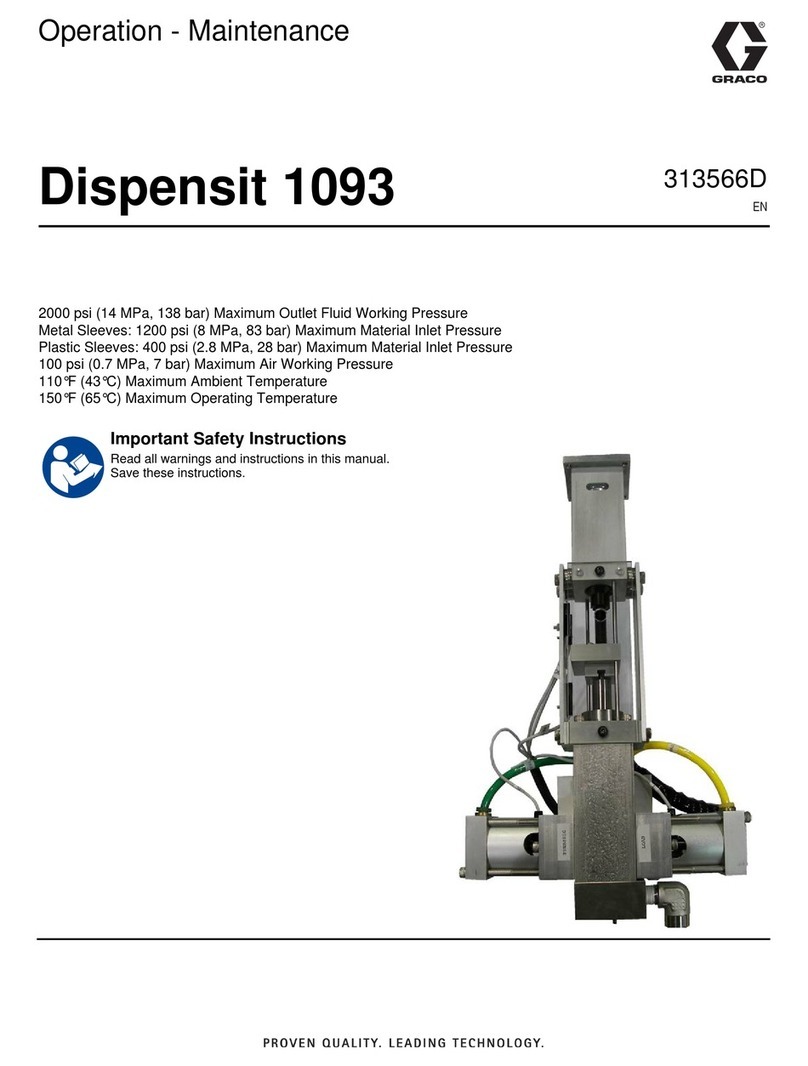

Graco 1093 Troubleshooting guide

Graco

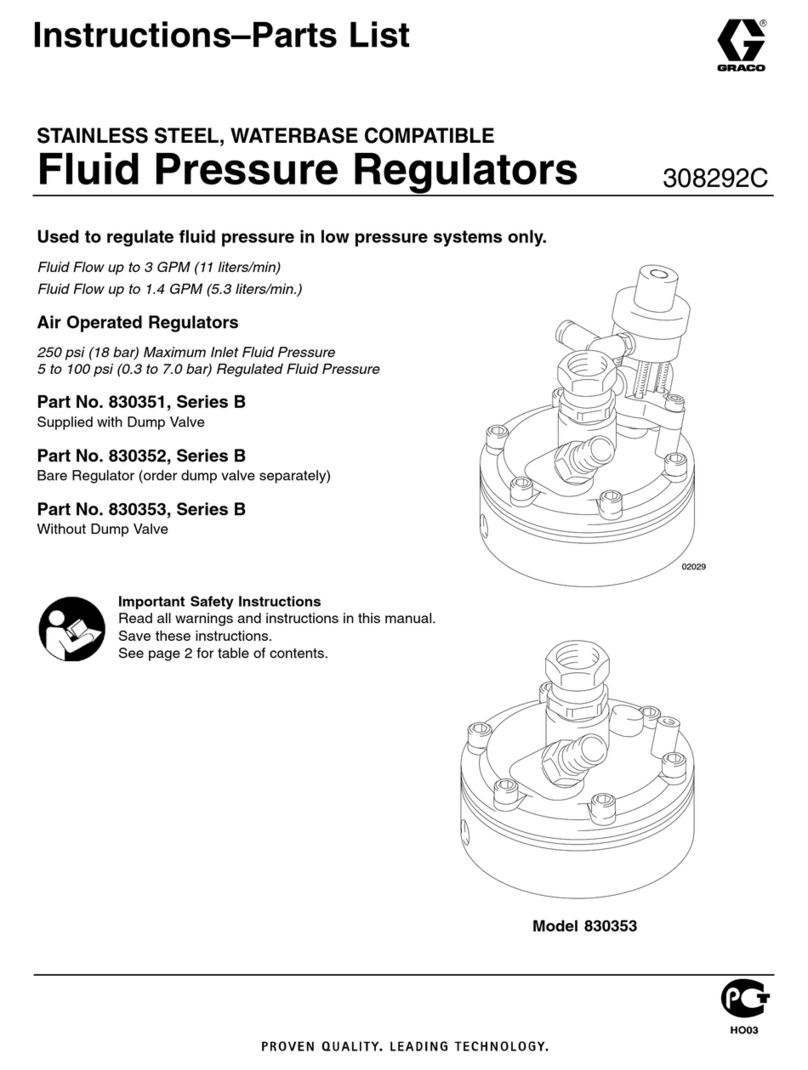

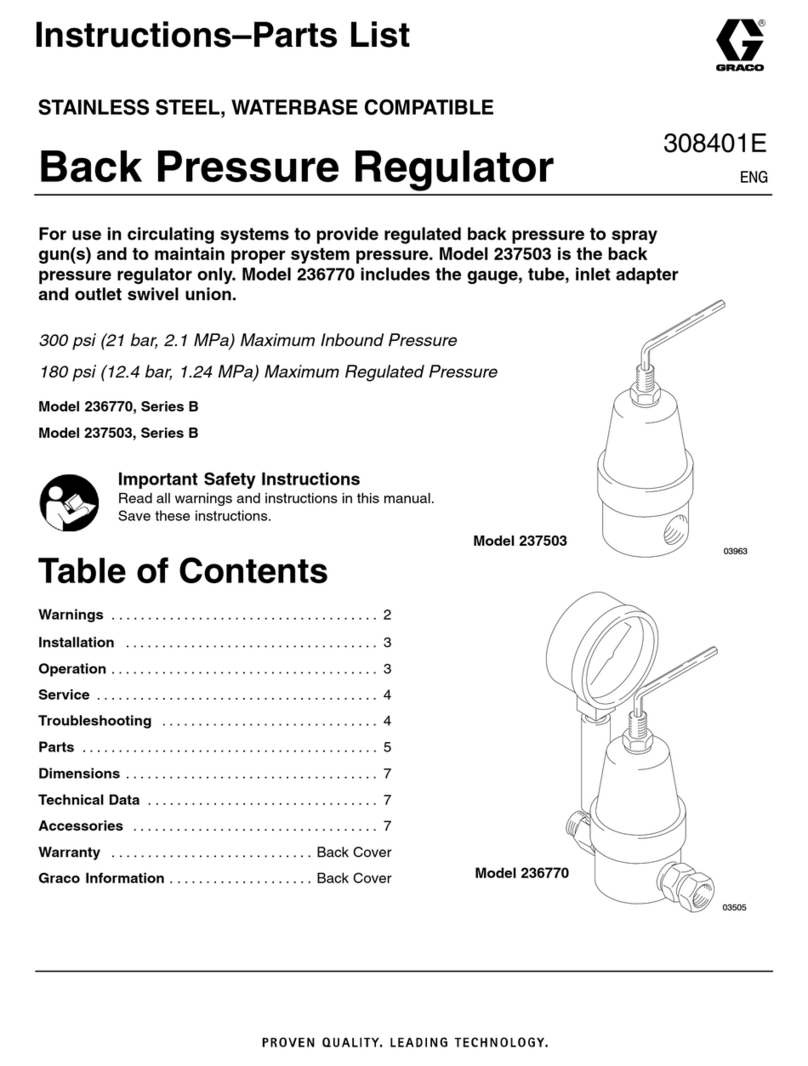

Graco Series B User manual

Graco

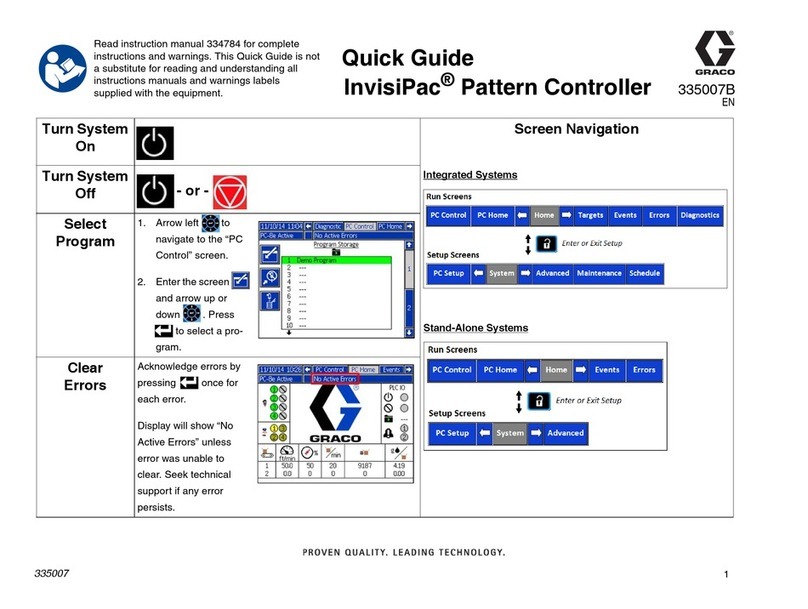

Graco InvisiPac User manual

Graco

Graco 237160 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions