Installation

Installation

Installation of this equipment involves potentially

hazardous procedures. Only trained and qualified

personnel who have read and who understand

the information in this manual should install this

equipment.

NOTE: To install an advanced motor, also see

Intrinsically Safe Installation Requirements for

Advanced Motors, page 12.

Fill With Oil Before Using Equipment

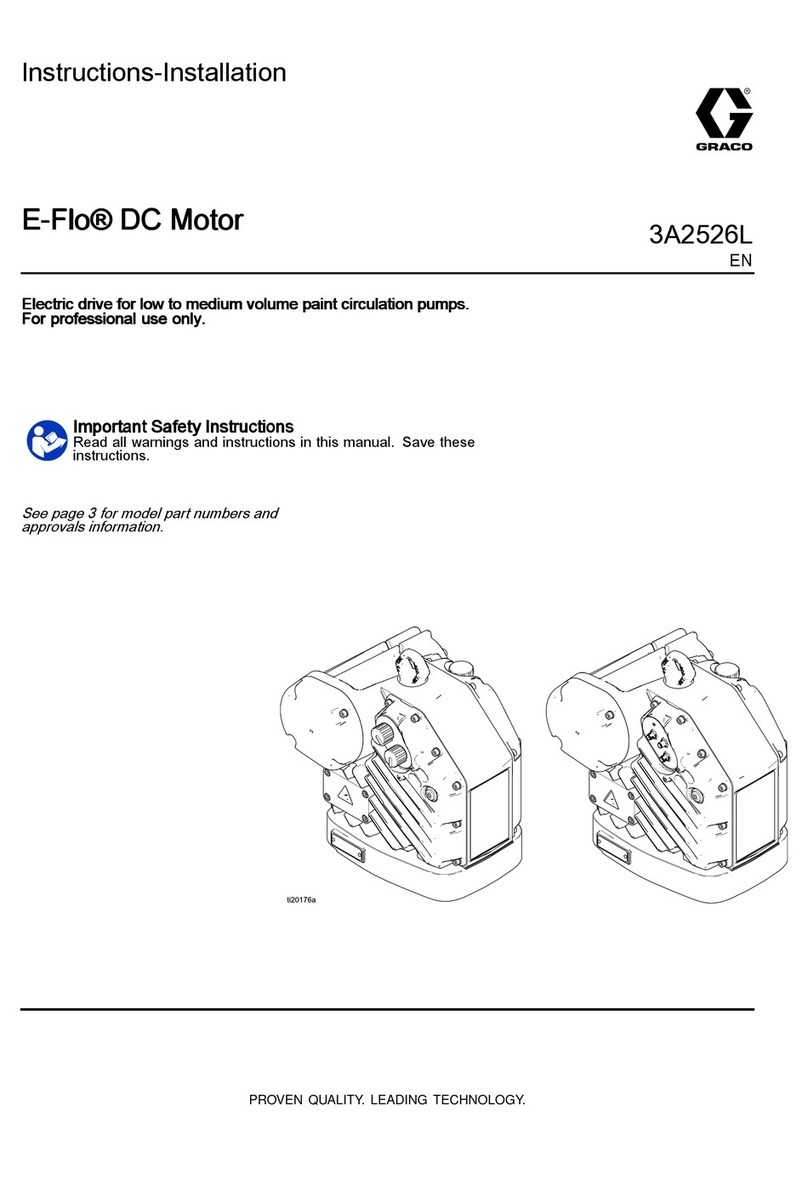

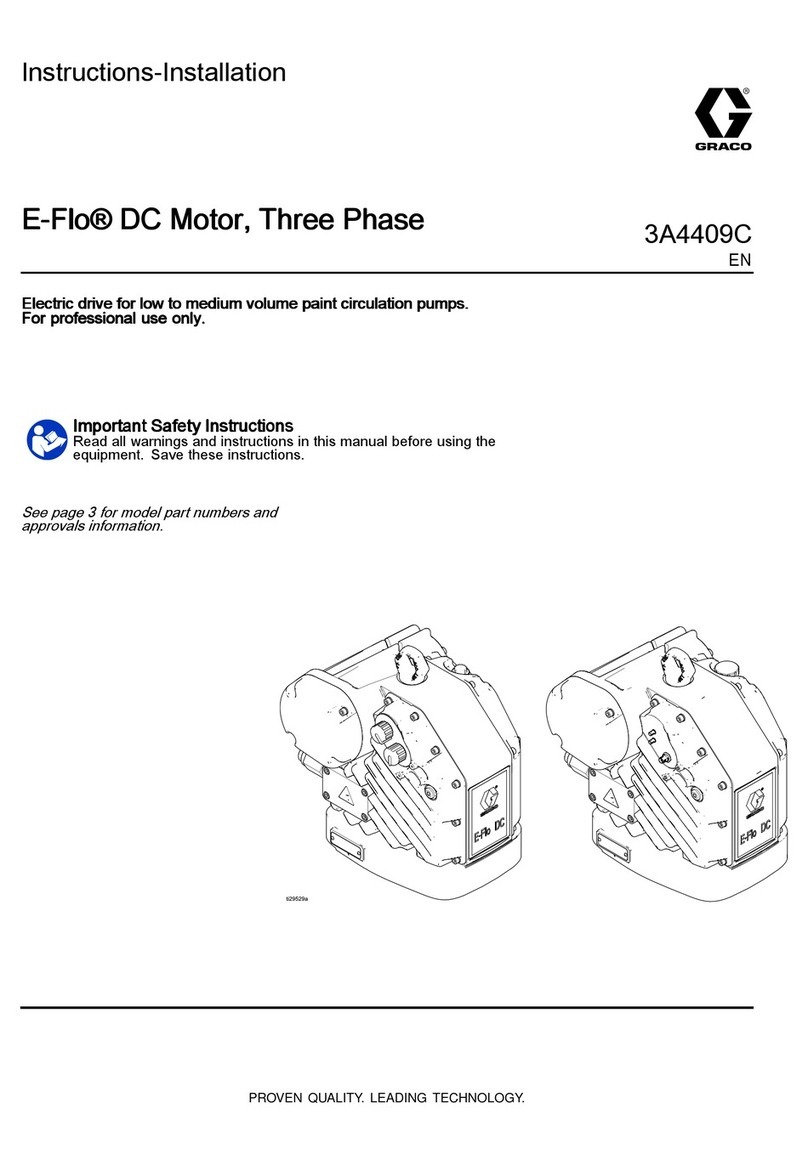

See Fig. 5. Before using the equipment, open the fill

cap (P) and add Graco Part No. 16W645 ISO 220

silicone-free synthetic gear oil. Check the oil level in

the sight glass (K). Fill until the oil level is near the

halfway point of the sight glass. The oil capacity is

approximately 1.5 quarts (1.4 liters). Do not overfill.

NOTE: Two 1 quart (0.95 liter) bottles of oil are

supplied with the equipment.

Figure 5 Sightglass and Oil Fill Cap

Power Supply Requirements

Improper wiring may cause electric shock or other

serious injury if work is not performed properly.

Have a qualified electrician perform any electrical

work. Be sure your installation complies with all

National, State and Local safety and fire codes.

See Table 1 for power supply requirements. The

system requires a dedicated circuit protected with a

circuit breaker.

Table 1 . Power Supply Specifications

Model* Voltage Phase Hz Current

EM001x 100–250

Vac

1 50/60 20 A

EM002x 200–250

Vac

1 50/60 20 A

* The last digit of the Model No. varies. See the

Models tables on pages 3–6.

Hazardous Area Cabling and Conduit

Requirements

Explosion Proof

All electrical wiring in the hazardous area must be

encased in Class I, Division I, Group D approved

explosion-proof conduit. Follow all National, State,

and Local electric codes.

A conduit seal (D) is required within 18 in. (457 mm)

of the motor for the US and Canada. See Fig. 7.

All cables must be rated at 70°C.

Flame Proof (ATEX)

Use appropriate conduit, connectors, and cable

glands rated for ATEX II 2 G. Follow all National,

State, and Local electric codes.

All cable glands and cables must be rated at 70°C.

10 3A2526D