Grounding

311238ZAM 9

Motor Lubrication

Graco does not require lubrication beyond the grease

installed at the factory or through regular maintenance.

With good quality compressed air and normal ambient

conditions NXT air motors will run millions of cycles

without additional lubrication.

However, if any of the following criteria apply to your

system, you will benefit from installing a 3/4 in. air line

lubricator in the air line before the air motor or from

occasionally adding oil to an air filter cup.

• Air supply does not contain any oil.

• Air supply is very wet.

• Air supply is very dry.

• Air motor is run at low air pressure.

• Air motor is run in unusually hot or cold environ-

ments.

Areas that benefit from lubrication:

• main piston o-rings(17),

• sliding valve spool(119/108), and

• motor detent assembly (113).

Add Lubrication

The three methods for adding lubrication are described

below.

Lubricate Air Valve

Perform these steps annually, or more often depending

on your duty cycle, air pressure, and air quality. Use a

high quality lithium-based grease.

1. Remove the 10 air valve cover screws (124) and air

valve cover (112).

2. Grease all visible moving parts, especially detent

(113) and valve pistons (119).

Lubricate Air Filter Bowl

If using a motor with integrated air controls, add 50-75

ml of oil to the air filter bowl and run the motor for a few

minutes at a fast cycle rate. The oil will move through

the air valve and main piston.

Add Accessory Air Lubricator

If using an air motor with integrated air controls, add an

accessory airline lubricatorto the motor inlet. The oil

will move through the air filter.

Graco offers airline lubricators for NXT air motors.

Order 214848 (1/2 in.) for NXT 2200 and NXT 3400

air motors. Order 214849 (3/4 in.) for NXT 6500 air

motors.

If using an air motor without integrated air controls, add

a standard type filter/regulator/lubricator that is sized for

the specific air motor, such as 217073 (3/4 in.) or

217072 (1/2 in.).

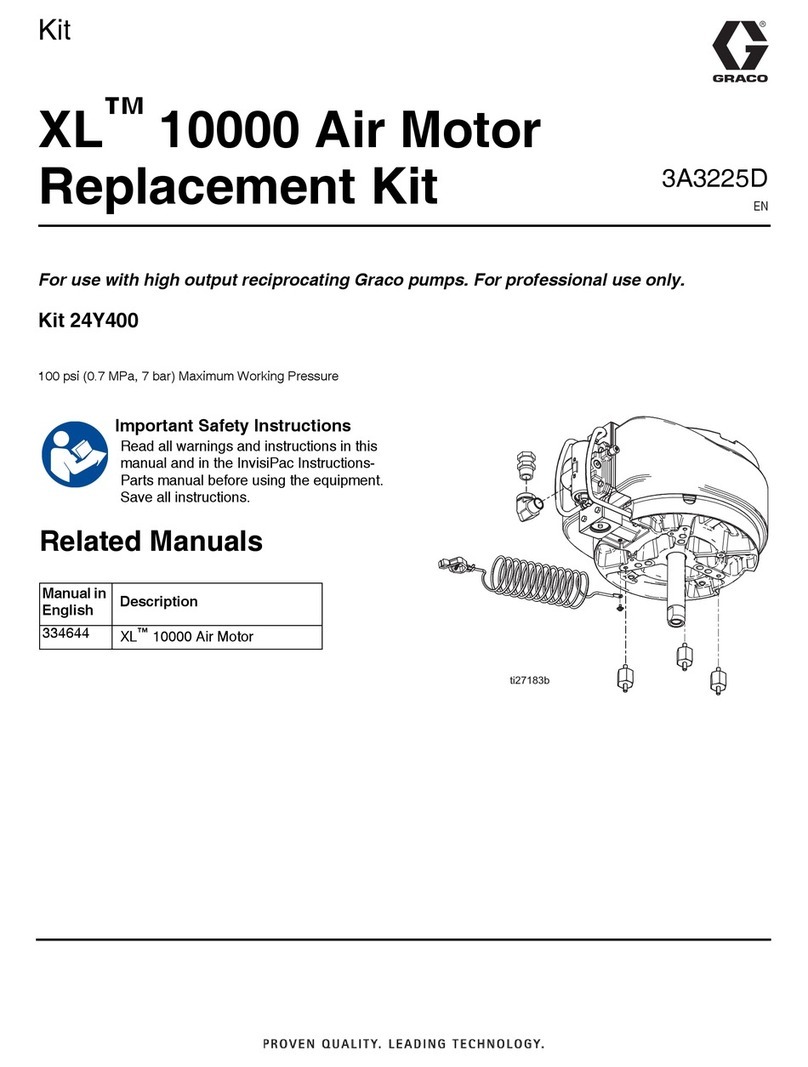

Grounding

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

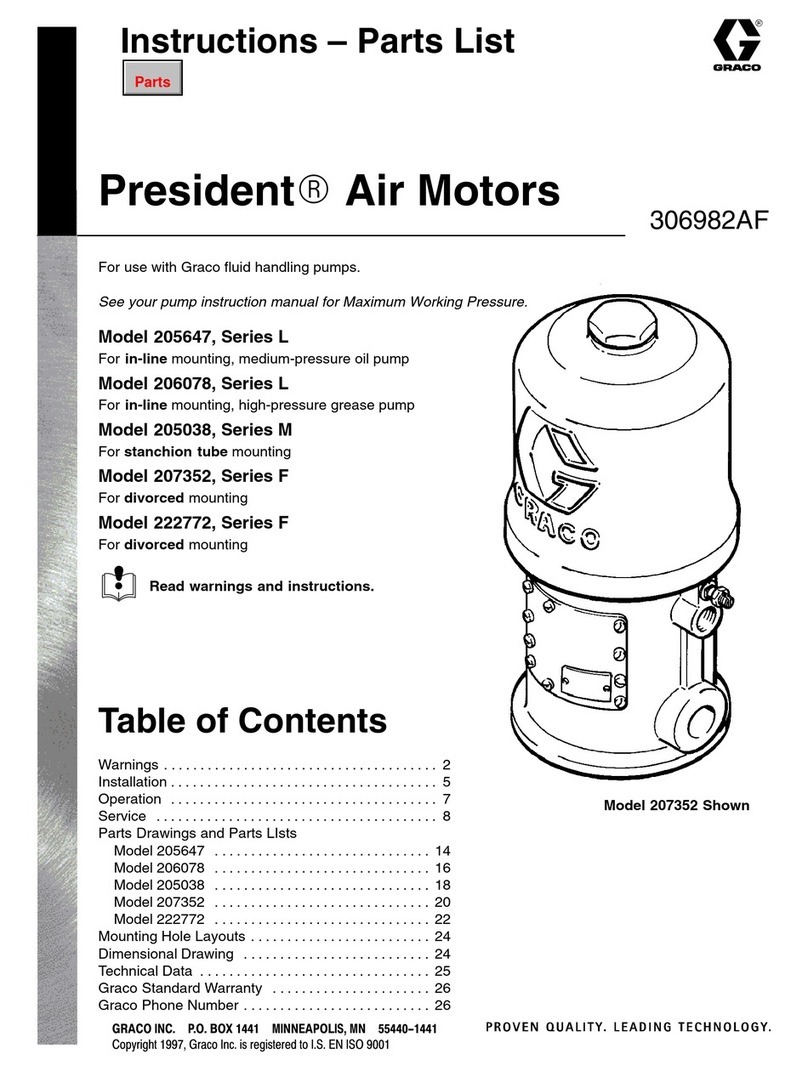

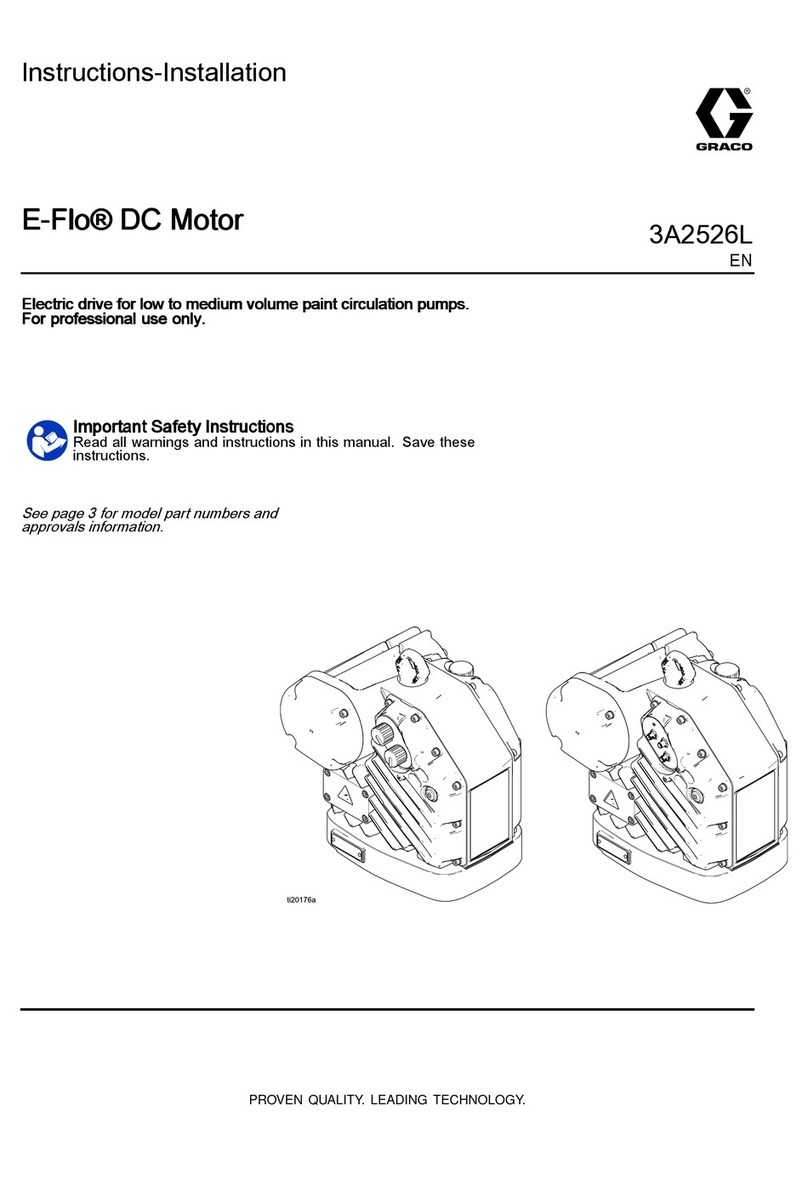

See FIG. 2. Use the ground screw (60) and lockwasher

(61) to attach Part No. 244524 Ground Wire (GW) at the

rear of the air motor. Tighten the screw securely. Con-

nect the other end of the ground wire to a true earth

ground.

It is normal for some oil to come out through the

exhaust.

Depending on air quality you may need to change

the air filter more frequently.

The equipment must be grounded to reduce the risk of

static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

FIG. 2. Ground Wire