2 3A7467E

Contents

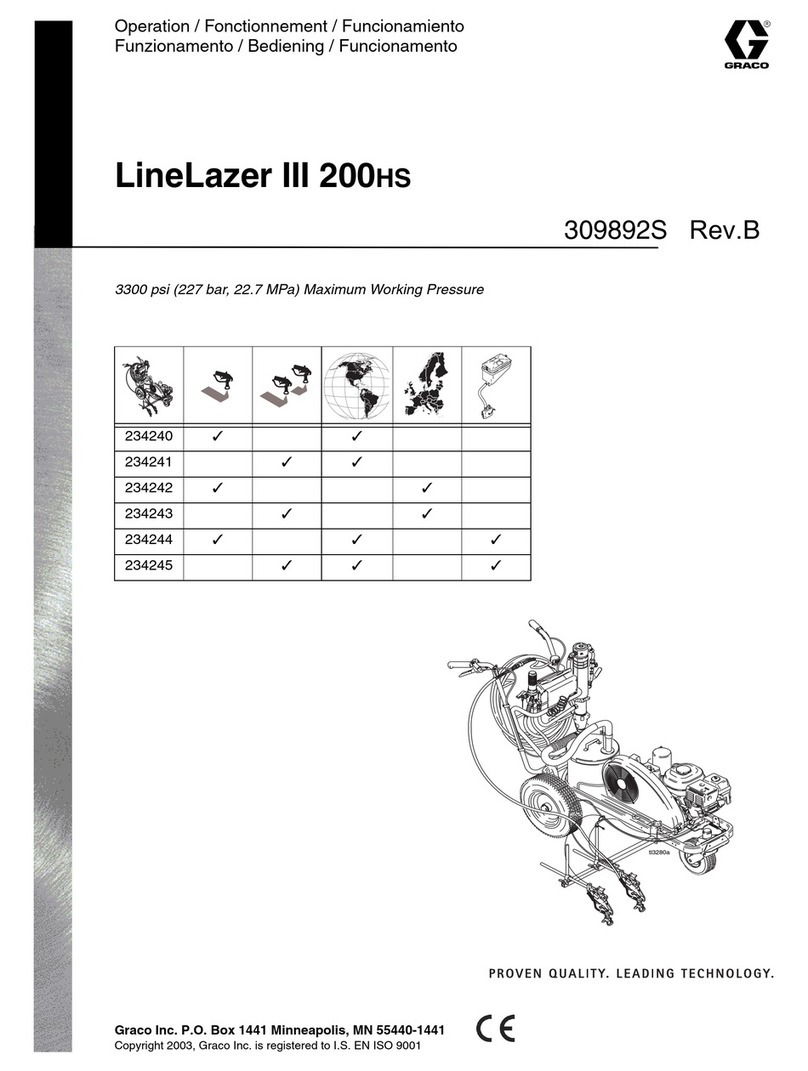

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Series Change Information . . . . . . . . . . . . . . . . . 5

Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Component Identification . . . . . . . . . . . . . . . . . . . 10

MediaTrak Controls . . . . . . . . . . . . . . . . . . . . . . 11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Grounding (ATEX systems only) . . . . . . . . . . . . 12

Lifting the System . . . . . . . . . . . . . . . . . . . . . . . 12

Blast Hose Control Selection . . . . . . . . . . . . . . 13

Blasting on Higher Surfaces . . . . . . . . . . . . . . . 13

Pinch Hose Inspection . . . . . . . . . . . . . . . . . . . 13

Connect the Blast Hose and Air Hose . . . . . . . 14

Connect the Water Supply . . . . . . . . . . . . . . . . 15

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fill the Water Tank . . . . . . . . . . . . . . . . . . . . . . 16

Fill Pot with Abrasive Media . . . . . . . . . . . . . . . 17

Pressurize the Pot . . . . . . . . . . . . . . . . . . . . . . . 18

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pressure Relief Procedure . . . . . . . . . . . . . . . . 19

Adjust Blast Pressure . . . . . . . . . . . . . . . . . . . . 20

Adjust Abrasive Media . . . . . . . . . . . . . . . . . . . 20

Refill Pot with Media . . . . . . . . . . . . . . . . . . . . . 21

Set the Abrasive Metering Value . . . . . . . . . . . 21

Optimize the Abrasive Metering Value . . . . . . . 21

General Application Guides . . . . . . . . . . . . . . . 22

Nozzle Selection Guide . . . . . . . . . . . . . . . . . . . 23

Blast Pressure vs. Air Flow Guide . . . . . . . . . . . 23

Use the Wash Feature . . . . . . . . . . . . . . . . . . . 24

Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Drain the Pot . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Winterize the Equipment . . . . . . . . . . . . . . . . . . 27

Clean the Water Tank . . . . . . . . . . . . . . . . . . . . 28

Use the Water Dose Meter . . . . . . . . . . . . . . . . 28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Replace the DataTrak Battery . . . . . . . . . . . . . . 35

Replace the DataTrak Fuse . . . . . . . . . . . . . . . . 36

Replace the Pinch Hose . . . . . . . . . . . . . . . . . . 37

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

EQs Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

EQc and EQ200T / EQ400T Models . . . . . . . . . 42

EQ200T Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 44

EQ400T Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Enclosure Box Parts . . . . . . . . . . . . . . . . . . . . . 48

Enclosure Parts . . . . . . . . . . . . . . . . . . . . . . . . . 52

Blast Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Vapor Abrasive Blast Systems and

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

50 ft (15 m) Blast Hoses with Control

Hose/Cable . . . . . . . . . . . . . . . . . . . . . . . . . 56

50 ft (15 m) Blast Hoses without Control

Hose/Cable . . . . . . . . . . . . . . . . . . . . . . . . . 56

Control Hoses/Cable with Blast Hose . . . . . . . . 56

Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

EQ200T (M58 Kaeser Compressor) . . . . . . . . . 57

EQ400T (Atlas Copco Compressor) . . . . . . . . . 57

Other Accessories . . . . . . . . . . . . . . . . . . . . . . . 57

Common Spare Parts . . . . . . . . . . . . . . . . . . . . 58

Tubing Schematic . . . . . . . . . . . . . . . . . . . . . . . . . 59

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

EQs and EQs Elite Models . . . . . . . . . . . . . . . . 60

EQc Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

EQ Trailer Models . . . . . . . . . . . . . . . . . . . . . . . 61

Trailer Kit Compressor Installation Guidelines

(279960, 279970) . . . . . . . . . . . . . . . . . . . . 62

Trailer Mounting Area Dimensions . . . . . . . . . . 62

Technical Specifications . . . . . . . . . . . . . . . . . . . . 64

EQs Elite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

EQc and EQc Elite . . . . . . . . . . . . . . . . . . . . . . . 65

EQ200T Elite . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

EQ400T Elite . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

California Proposition 65 . . . . . . . . . . . . . . . . . . 67

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 68