308944

Rev. A

First choice when

quality counts.

t

8922A

INSTRUCTIONS-PARTS LIST

INSTRUCTIONS

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

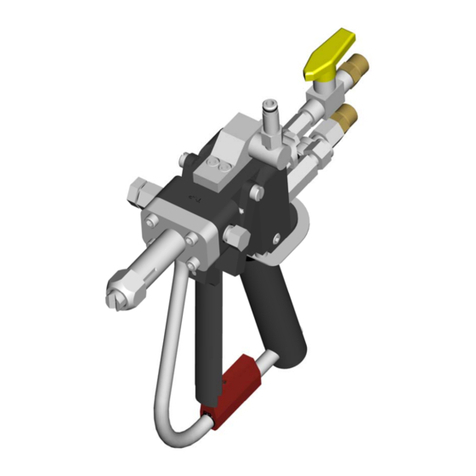

Kit, Reversible Handle

Line Lazer 3900, 5900

3300 psi (230 bar, 23 MPa ) Maximum Working Pressure

Model 240714, Series A

Related Manuals

Operation 308873. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair 308874. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you:

Dare instructed to relieve the pressure,

Dstop spraying,

Dcheck or service any of the system equipment,

Dor install or clean the spray tip.

Pressure Relief Procedure

1. Lock gun trigger safety.

2. Turn engine ON/OFF switch to OFF.

3. Move pressure control switch to OFF and turn

pressure control knob fully counterclockwise.

4. Unlock trigger safety. Hold metal part of gun firmly

to side of grounded metal pail, and trigger gun to

relieve pressure.

5. Lock gun trigger safety.

6. Open pressure drain valve. Leave valve open until

ready to spray again.

7. Disconnect spark plug cable.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above,

VERY SLOWLY

loosen tip guard retaining nut or hose end coupling to

relieve pressure gradually, then loosen completely.

Now clear tip or hose.

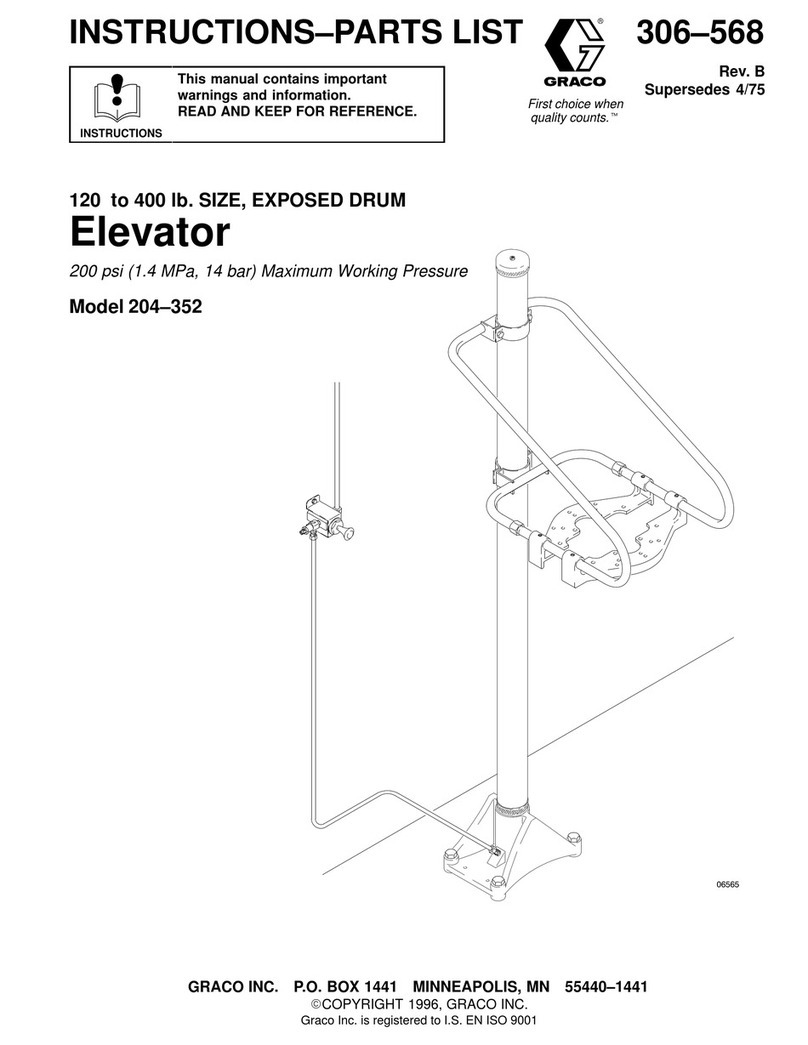

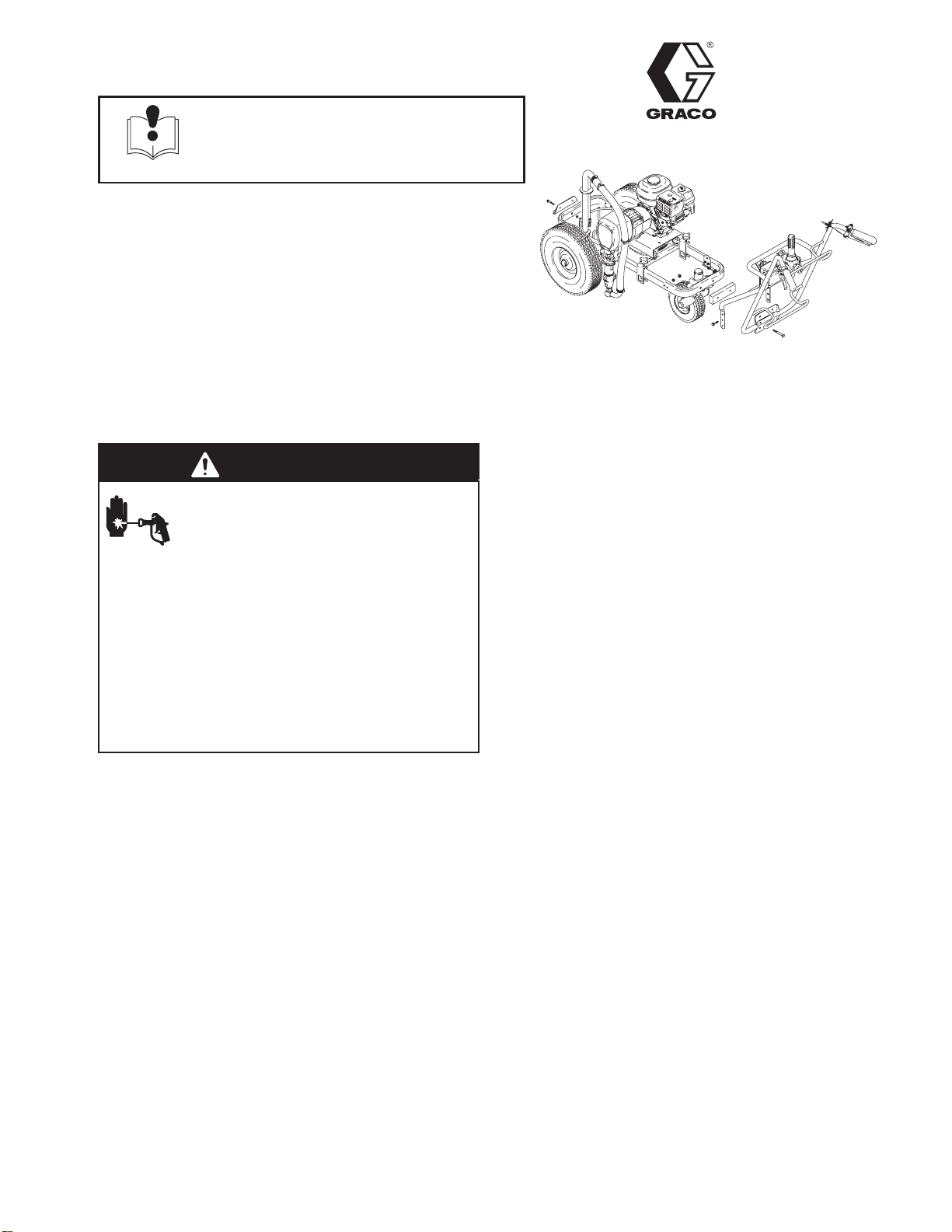

Remove Cables, Hoses, Wir-

ing, and Handle Assembly

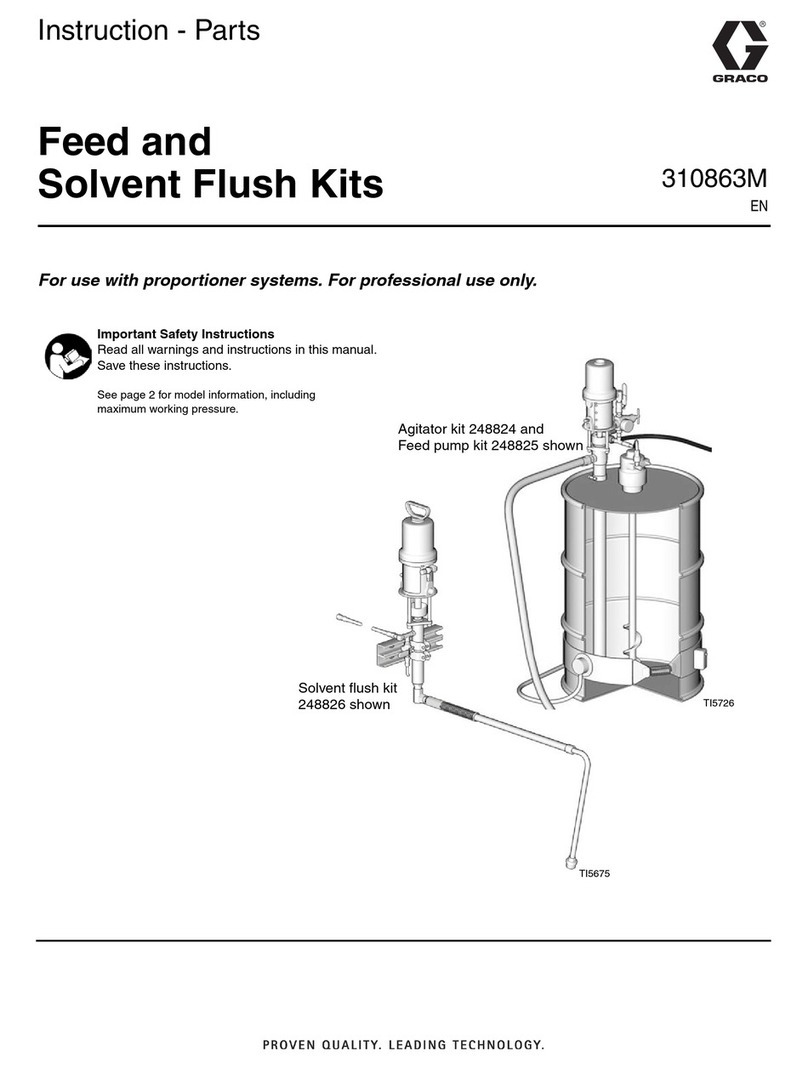

Fig. 1. Remove cables, hoses, wiring, and handle from

LineLazer cart as outlined in the following steps.

8. Unfasten paint gun cable (58) from linestriper

trigger (19). Remove spring clips (130) to free

cable from linestriper handle (24). Move cable and

clips aside for reassembly later.

9. Unfasten swivel wheel cable (102) from actuator

lever (101). Remove spring clips (130) to free

cable from linestriper handle (24). Move cable and

clips aside for reassembly later.

10. Separate gun hose (17) from coupled hose (11).

Move gun hose aside for rerouting during reas-

sembly.

11. Unfasten coupled hose (25) from pressure

control (2). Move aside for rerouting later.

12. Disconnect power cable (62) from pressure

control (2). Move aside for rerouting later.

13. Remove mounting bracket (103), brake rod (105),

attaching hardware: two flange screws (54) and

two lock nuts (55).

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 1999, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001