TABLE of CONTENTS

1. INTRODUCTION ............................................................................................................................................................1

2. MODELS...........................................................................................................................................................................2

2.1 MODELS 4200 AND 4200L ............................................................................................................................................2

2.2 MODEL 4202.................................................................................................................................................................3

2.3 MODEL 4210.................................................................................................................................................................3

3. PRIOR TO INSTALLATION.........................................................................................................................................4

3.1 ADJUSTING MODEL 4200 TO THE DESIRED RANGE........................................................................................................4

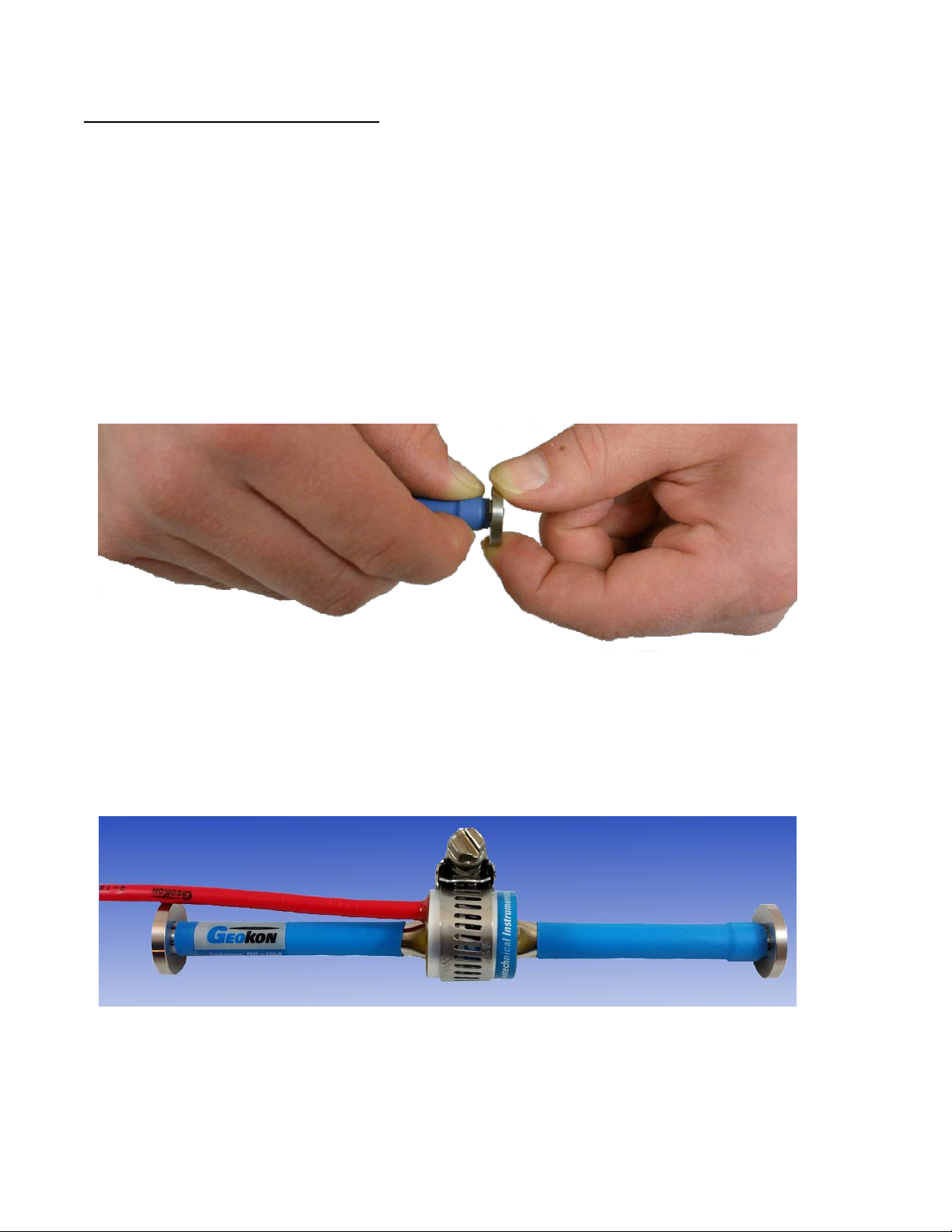

3.2 GAGE AND CABLE ASSEMBLY.......................................................................................................................................4

3.3PRELIMINARY CHECK ....................................................................................................................................................5

4. INSTALLING THE GAGES IN CONCRETE..............................................................................................................5

4.1 DIRECT ATTACHMENT TO REBAR..................................................................................................................................6

4.2 SUSPENSION METHOD...................................................................................................................................................7

4.3 ALTERNATIVE SUSPENSION METHOD............................................................................................................................8

4.4 USING PRECAST BRIQUETTES,SHOTCRETE,OR GROUTING............................................................................................8

4.5 CABLE SPLICING AND TERMINATION.............................................................................................................................9

4.6 LIGHTNING PROTECTION...............................................................................................................................................9

5. TAKING READINGS....................................................................................................................................................11

5.1 GK-404 READOUT BOX..............................................................................................................................................11

5.1.1 Operating the GK-404 .......................................................................................................................................11

5.2 GK-405 READOUT BOX..............................................................................................................................................12

5.2.1 Connecting Sensors............................................................................................................................................12

5.2.2 Operating the GK-405 .......................................................................................................................................12

5.3 GK-403 READOUT BOX (OBSOLETE MODEL) .............................................................................................................13

5.3.1 Connecting Sensors............................................................................................................................................13

5.3.2 Operating the GK-403 .......................................................................................................................................13

5.4 EMBEDMENT STRAIN GAGE READOUT POSITIONS.......................................................................................................13

5.5 MEASURING TEMPERATURES ......................................................................................................................................14

6. DATA REDUCTION......................................................................................................................................................15

6.1 READOUT BOX POSITION A.........................................................................................................................................15

6.2READOUT BOX POSITION B.........................................................................................................................................15

6.3 READOUT BOX POSITIONS D&E................................................................................................................................16

6.4 STRAIN RESOLUTION...................................................................................................................................................16

6.5 TEMPERATURE CORRECTIONS.....................................................................................................................................16

6.6 SHRINKAGE EFFECTS ..................................................................................................................................................18

6.7 CREEP EFFECTS...........................................................................................................................................................19

6.8 EFFECT OF AUTOGENOUS GROWTH.............................................................................................................................19

6.9 CONVERTING STRAIN TO LOAD...................................................................................................................................19

6.10 EFFECTIVE MODULUS ...............................................................................................................................................19

7. TROUBLESHOOTING.................................................................................................................................................20

APPENDIX A. SPECIFICATIONS..................................................................................................................................22

A.1 THERMISTOR..............................................................................................................................................................22

A.2 STRAIN GAGE.............................................................................................................................................................22

APPENDIX B. THEORY OF OPERATION ...................................................................................................................23

APPENDIX C. THERMISTOR TEMPERATURE DERIVATION..............................................................................26

APPENDIX D. HIGH TEMPERATURE THERMISTOR LINEARIZATION ...........................................................27

APPENDIX E. NO STRESS-STRAIN ENCLOSURE. ...................................................................................................28

APPENDIX F. MODEL 4200HT-T HIGH TEMPERATURE STRAIN GAGE ..........................................................29

APPENDIX G. MEASUREMENT AND CORRECTION OF TEMPERATURE EFFECTS.....................................30