2334130L

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

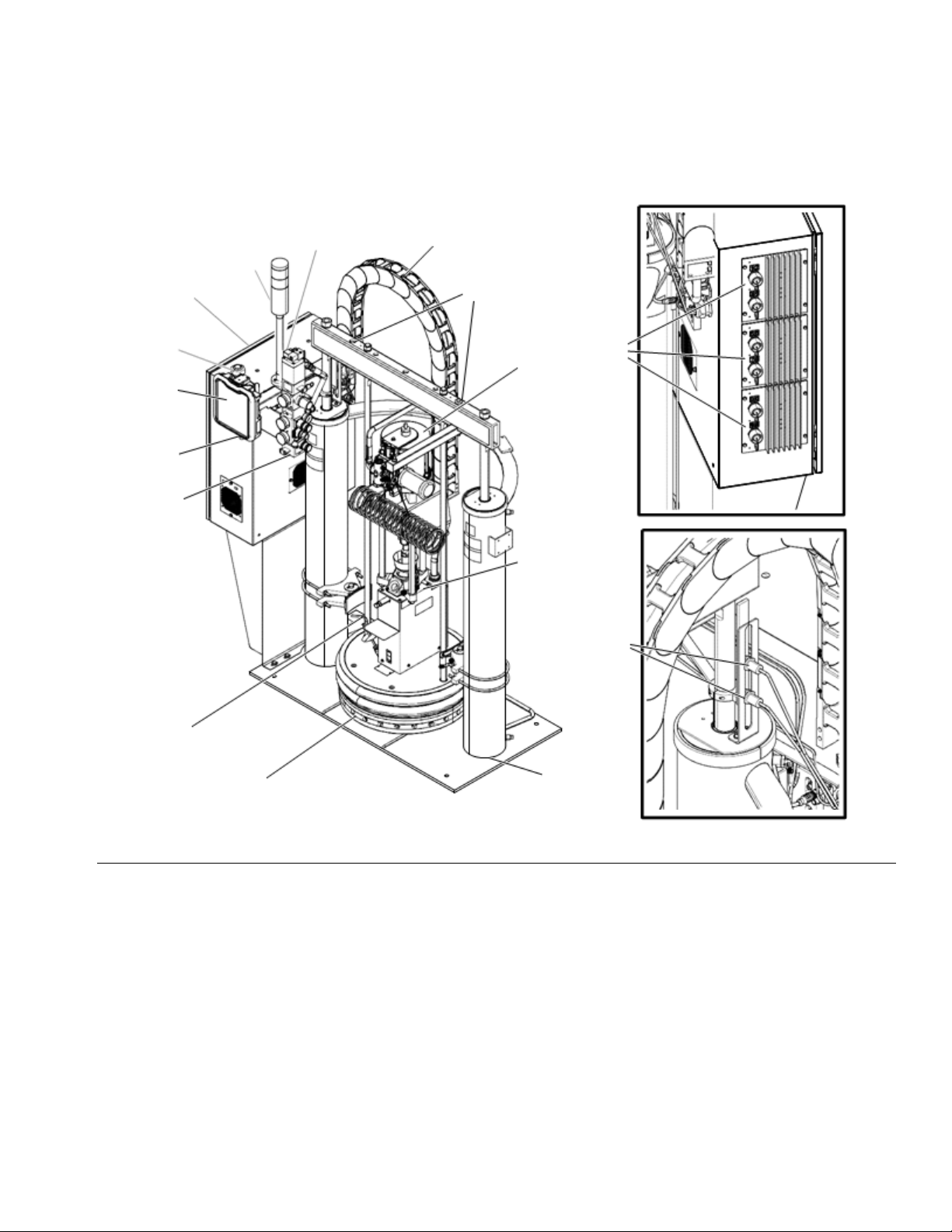

Component Identification . . . . . . . . . . . . . . . . . . . . 8

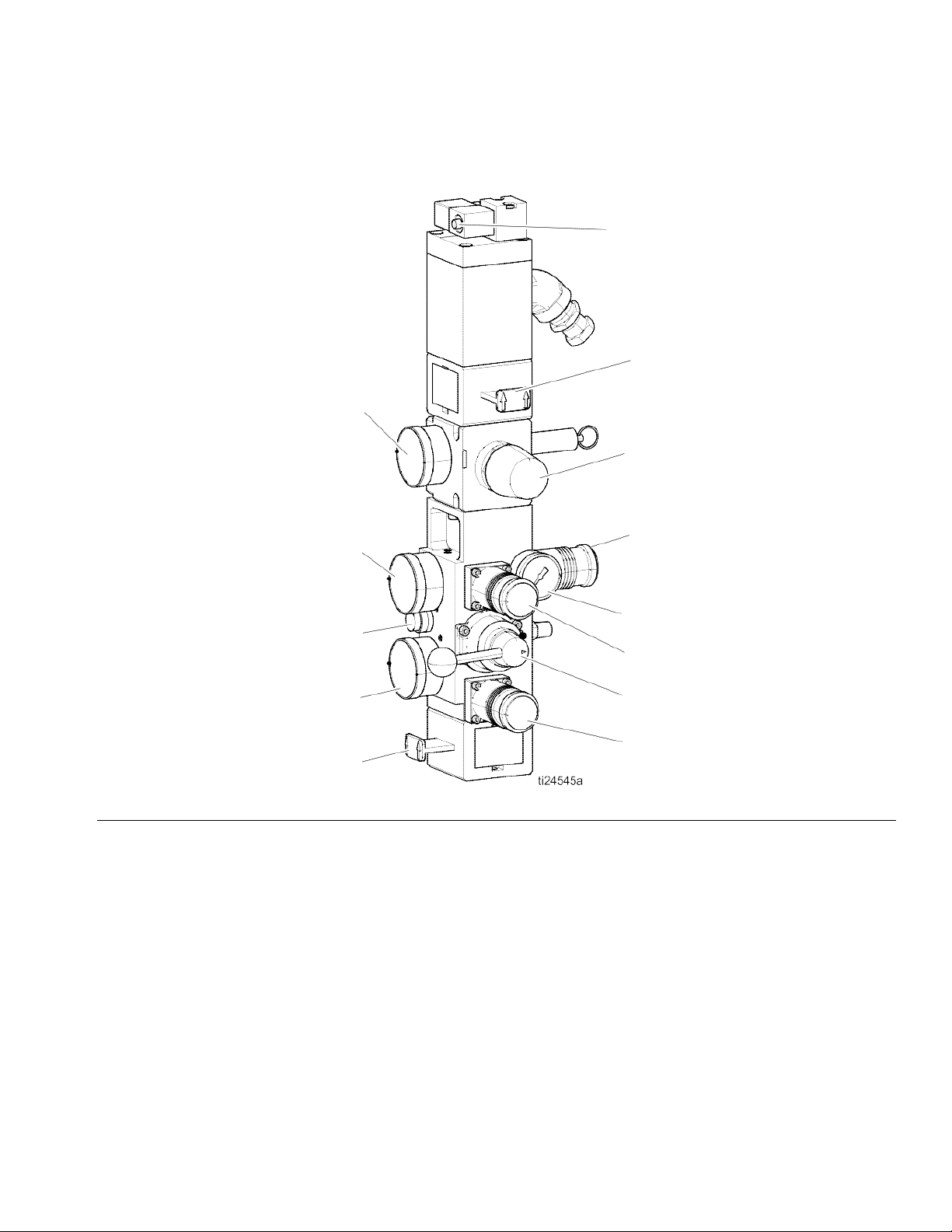

Integrated Air Controls . . . . . . . . . . . . . . . . . . . . 9

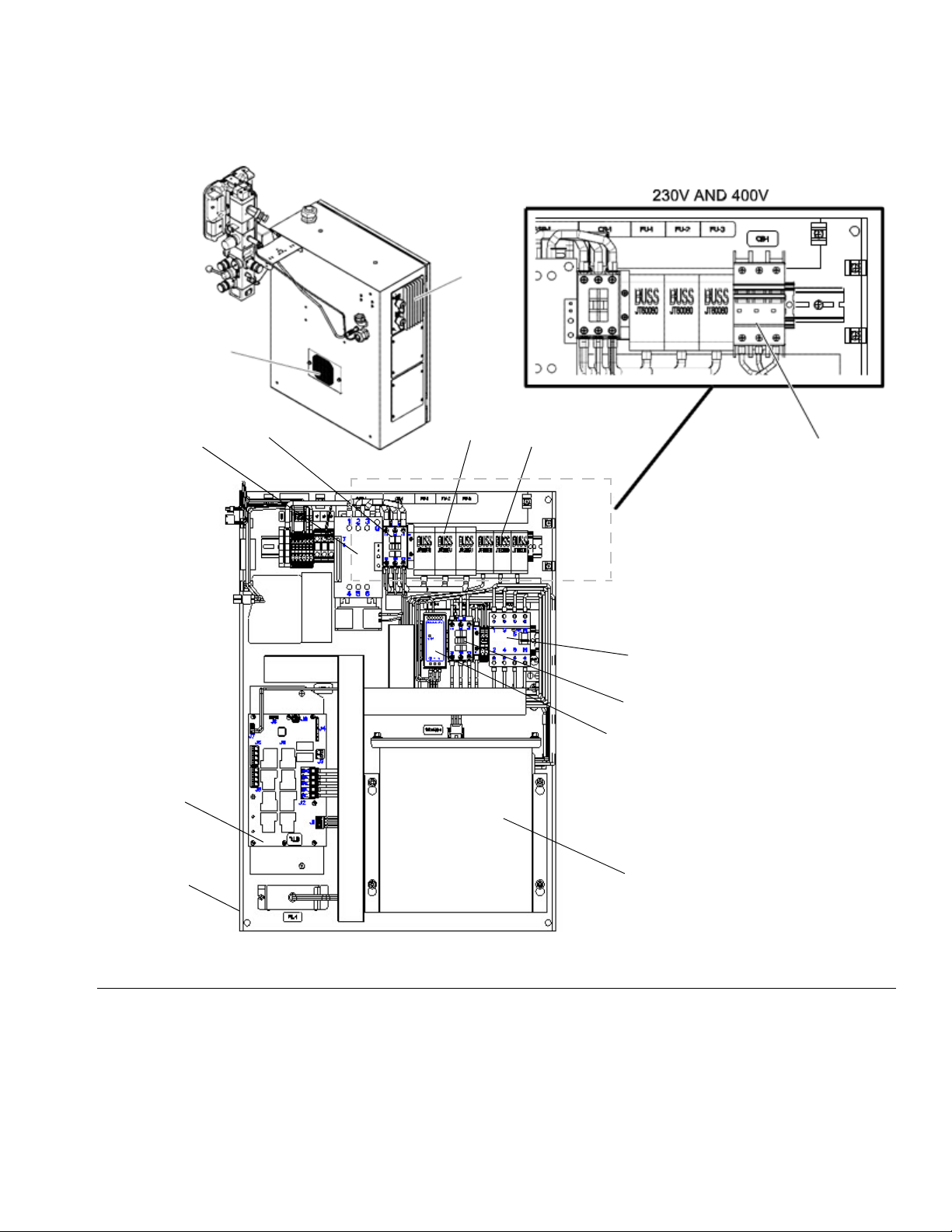

Electrical Control Enclosure . . . . . . . . . . . . . . . 10

Advanced Display Module (ADM) . . . . . . . . . . . 11

Screen Components . . . . . . . . . . . . . . . . . . . . . 13

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Air and Fluid Hoses . . . . . . . . . . . . . . . . . . . . . . 14

Heat Control Zone . . . . . . . . . . . . . . . . . . . . . . . 14

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Unpack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Location Requirements . . . . . . . . . . . . . . . . . . . 15

Install System . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Install Hydraulic Power Supply . . . . . . . . . . . . . 15

Mechanical Setup . . . . . . . . . . . . . . . . . . . . . . . 16

Install Heated Hose . . . . . . . . . . . . . . . . . . . . . . 17

Connect Multiple Devices . . . . . . . . . . . . . . . . . 18

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . 19

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connect Secondary System . . . . . . . . . . . . . . . 20

Check Sensor Resistance . . . . . . . . . . . . . . . . . 21

Check Heater Resistance . . . . . . . . . . . . . . . . . 22

Select ADM Settings . . . . . . . . . . . . . . . . . . . . . 23

Connect PLC (Hard Wired Interface Version) . . 25

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Purge System . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Load Material . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Heat Up System . . . . . . . . . . . . . . . . . . . . . . . . 30

Prime Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Prime System . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Setback Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Pressure Relief Procedure . . . . . . . . . . . . . . . . 34

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Change Drums . . . . . . . . . . . . . . . . . . . . . . . . . 36

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Light Tower (Optional) . . . . . . . . . . . . . . . . . . . 37

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ram Troubleshooting . . . . . . . . . . . . . . . . . . . . 44

Heated Pump Troubleshooting . . . . . . . . . . . . . 45

Air Motor Troubleshooting . . . . . . . . . . . . . . . . . 45

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Replace Wipers . . . . . . . . . . . . . . . . . . . . . . . . . 46

Replace Platen RTD . . . . . . . . . . . . . . . . . . . . . 46

Separate the Air Motor and Pump . . . . . . . . . . . 47

Remove Platen . . . . . . . . . . . . . . . . . . . . . . . . . 50

Replace Heater Band and Pump RTD . . . . . . . 50

Replace MZLP Fuse . . . . . . . . . . . . . . . . . . . . . 51

Replace MZLP . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Replace MZLP Daughter Card . . . . . . . . . . . . . 53

Replace AWB . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Replace Power Supply . . . . . . . . . . . . . . . . . . . 54

Replace Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Replace Transformer . . . . . . . . . . . . . . . . . . . . . 56

Update Software . . . . . . . . . . . . . . . . . . . . . . . . 58

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . 59

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Accessories and Kits . . . . . . . . . . . . . . . . . . . . . . . 89

Wiper Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Applicators and Dispense Valves . . . . . . . . . . . 89

CGM Installation Kit, 25C994 . . . . . . . . . . . . . . 89

Flow Control and Manifolds . . . . . . . . . . . . . . . . 89

Accessory Extension Cables . . . . . . . . . . . . . . . 90

Light Tower Kit, 24W589 . . . . . . . . . . . . . . . . . . 90

Heated Hoses and Fittings . . . . . . . . . . . . . . . . 91

8 Channel Upgrade Kit, 24V755 . . . . . . . . . . . . 93

12 Channel Upgrade Kit, 24V756 . . . . . . . . . . . 95

Appendix A - ADM . . . . . . . . . . . . . . . . . . . . . . . . . 98

General Operation . . . . . . . . . . . . . . . . . . . . . . . 98

ADM Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Screen Navigation . . . . . . . . . . . . . . . . . . . . . . . 98

Enable, Disable Heating System . . . . . . . . . . . . 98

Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Operation Screens . . . . . . . . . . . . . . . . . . . . . . 100

Setup Screens . . . . . . . . . . . . . . . . . . . . . . . . . 102

Appendix B - USB Data . . . . . . . . . . . . . . . . . . . . 107

Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Access Files . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Upload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

USB Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

System Settings File . . . . . . . . . . . . . . . . . . . . 108

System Language File . . . . . . . . . . . . . . . . . . . 109

Create Custom Language Strings . . . . . . . . . . 109

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Technical Specifications . . . . . . . . . . . . . . . . . . . 111

Graco Standard Warranty . . . . . . . . . . . . . . . . . . 112