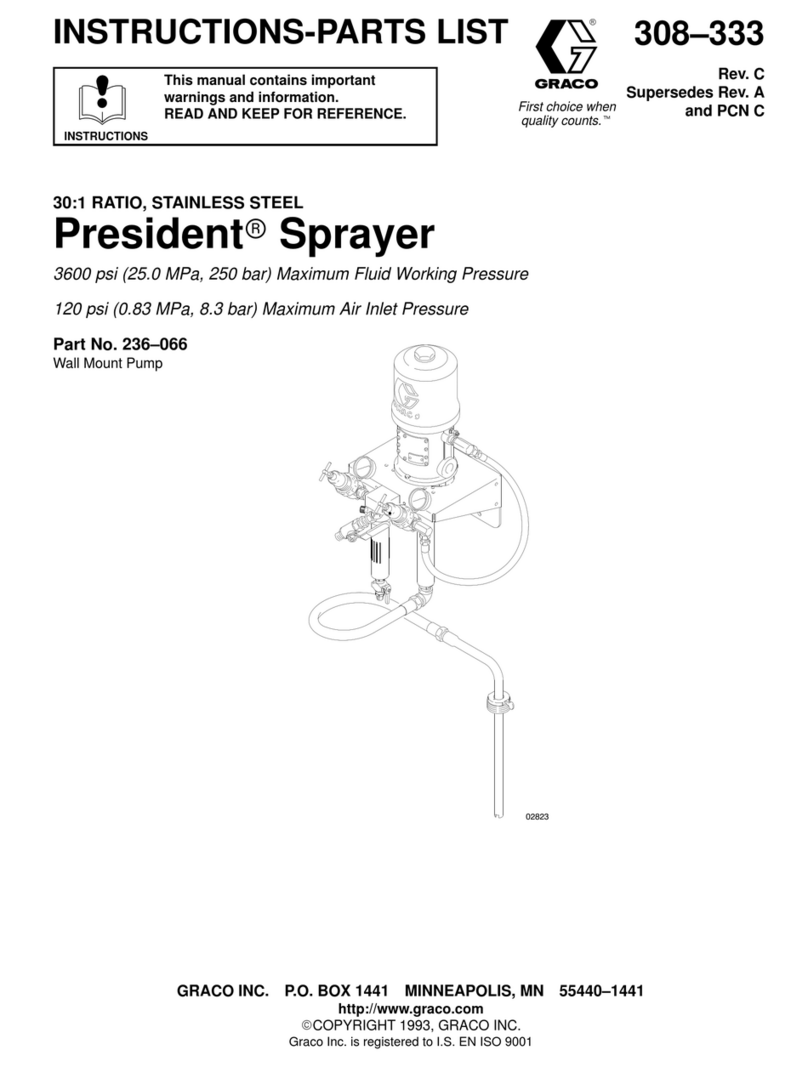

Graco 244113 User manual

Other Graco Paint Sprayer manuals

Graco

Graco 390 Hi-Boy User manual

Graco

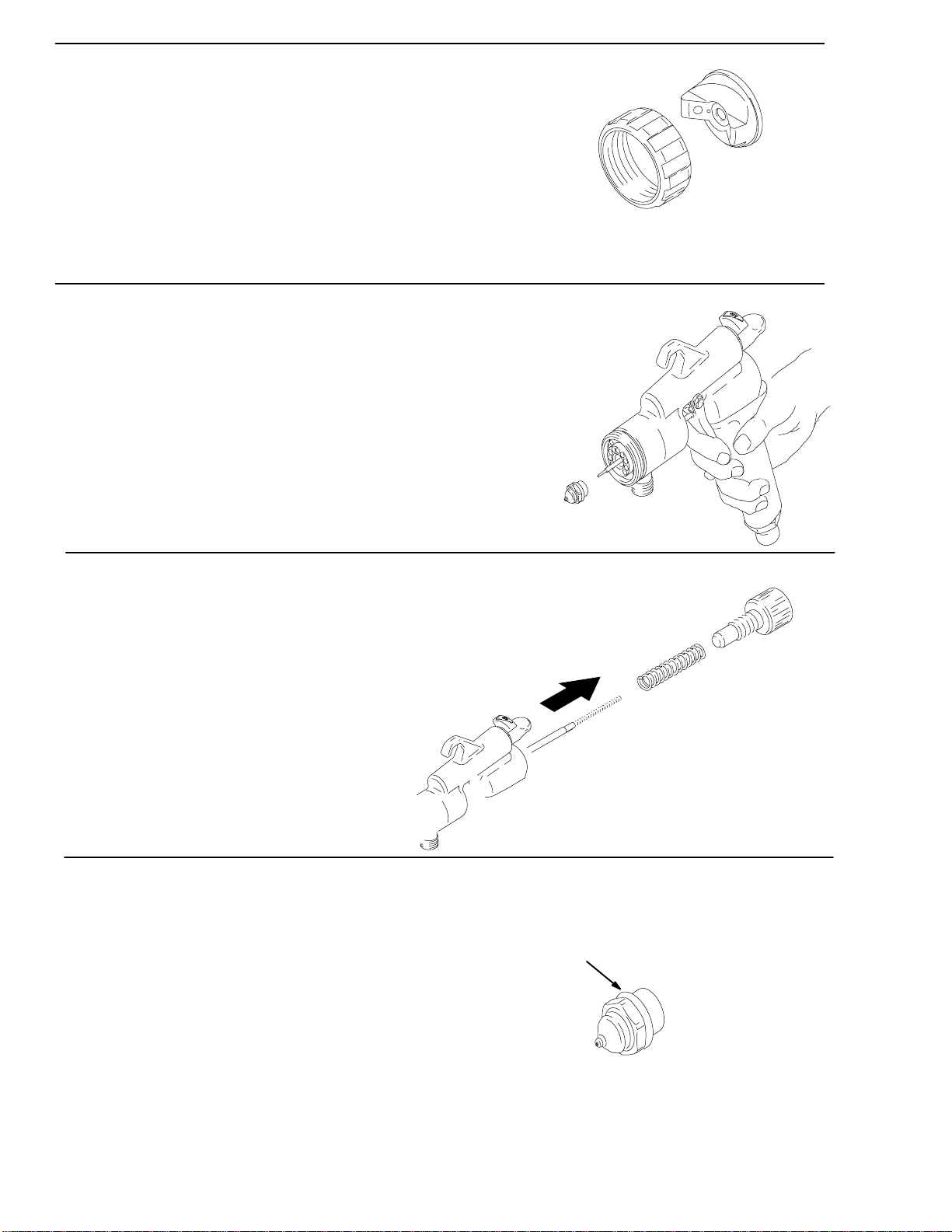

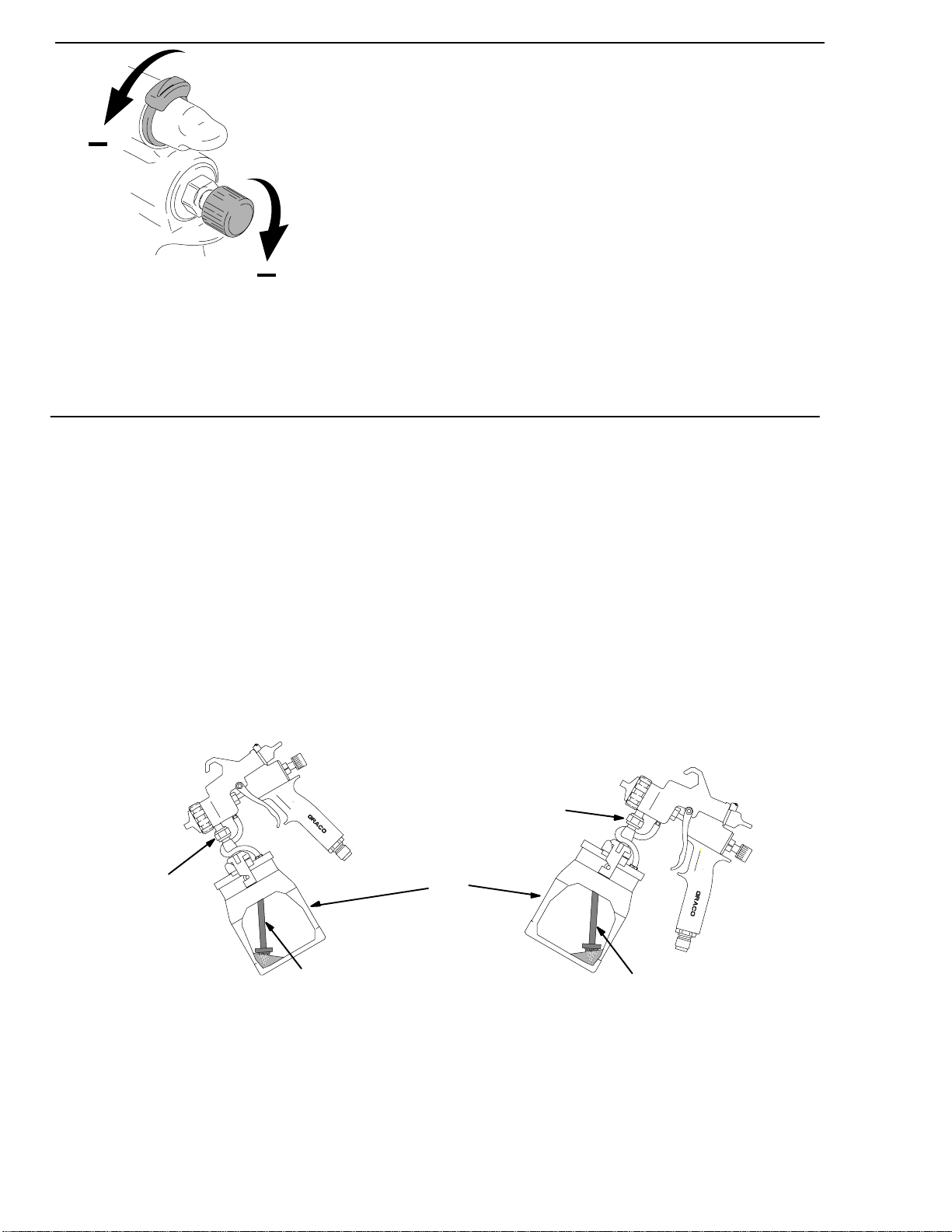

Graco AirPro 313869B User manual

Graco

Graco 3M Operation manual

Graco

Graco XP70 Parts list manual

Graco

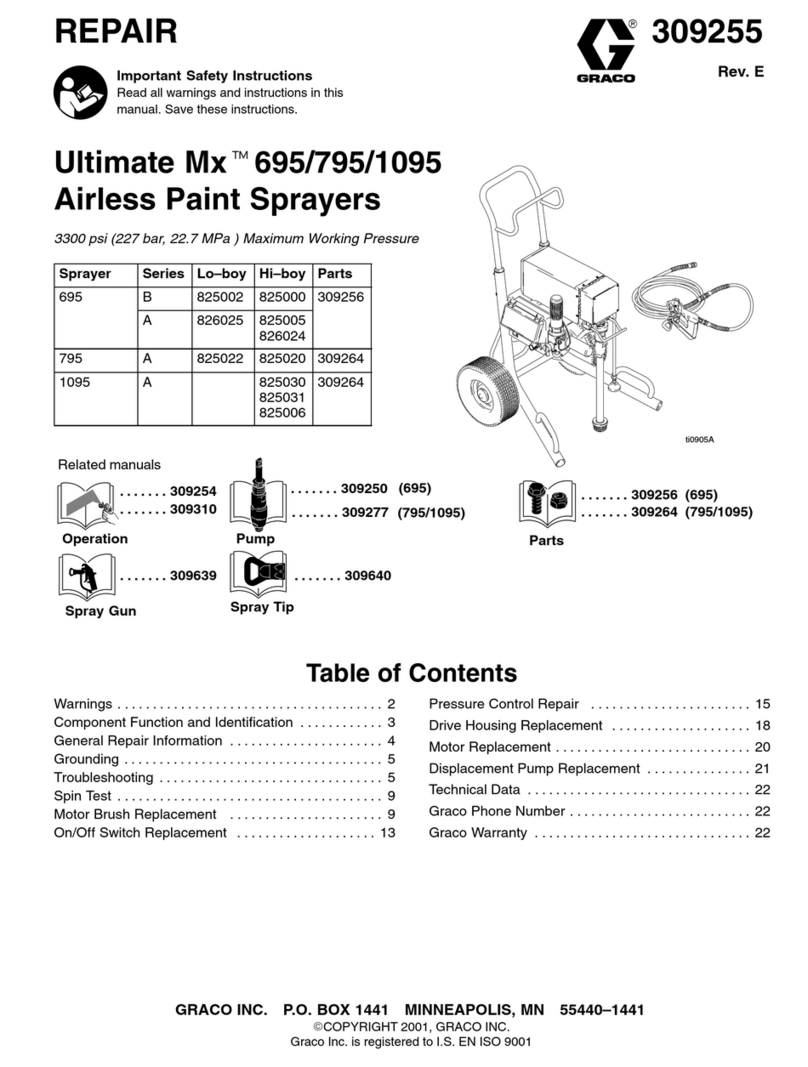

Graco Ultimate Mx II 695 User manual

Graco

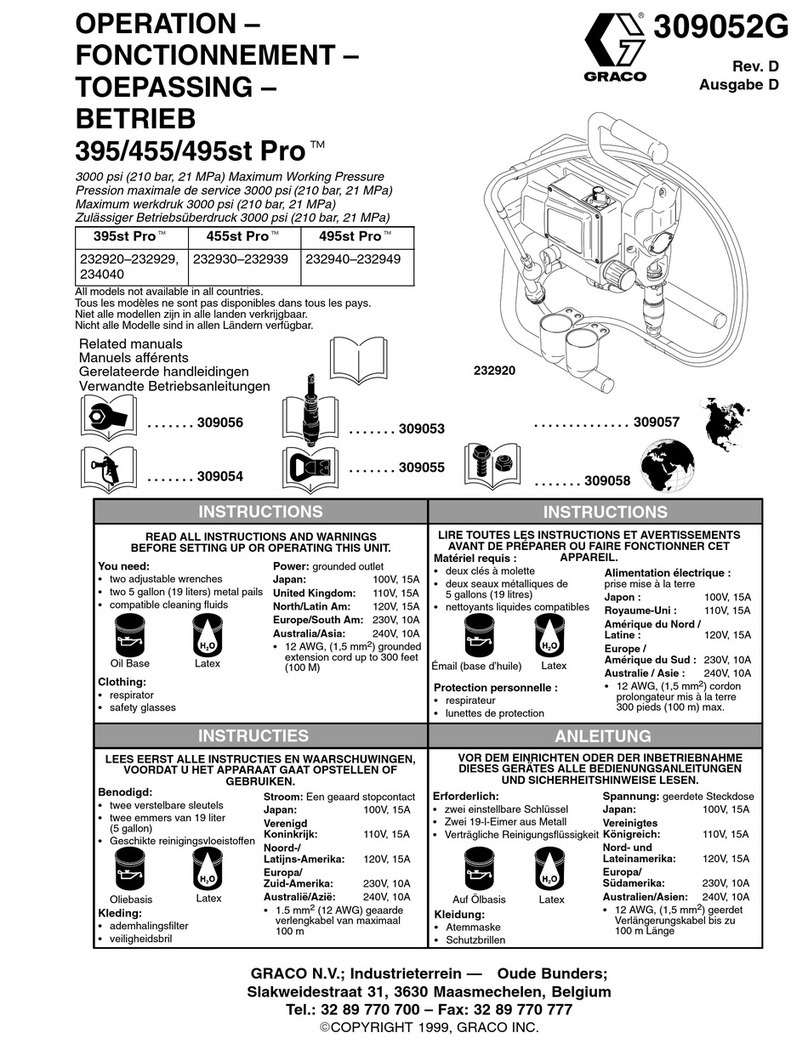

Graco 455st Pro Instruction Manual

Graco

Graco 231-034 Datasheet

Graco

Graco Ultimate Mx695 Setup guide

Graco

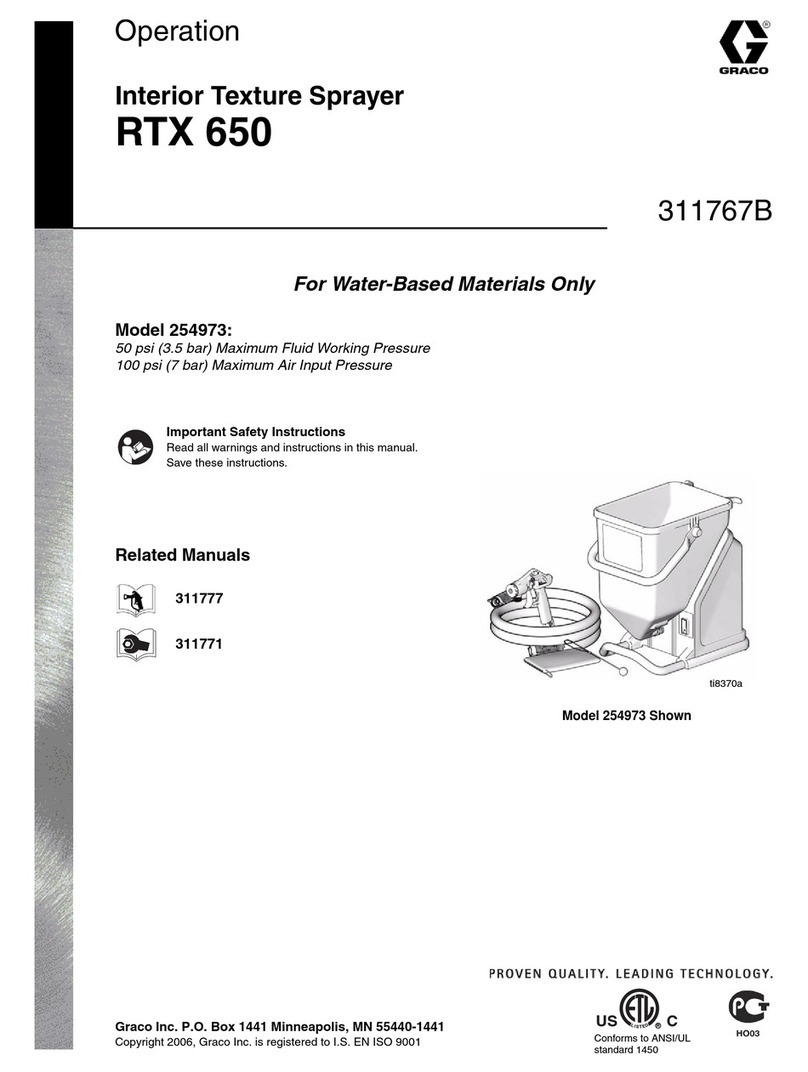

Graco 254973 User manual

Graco

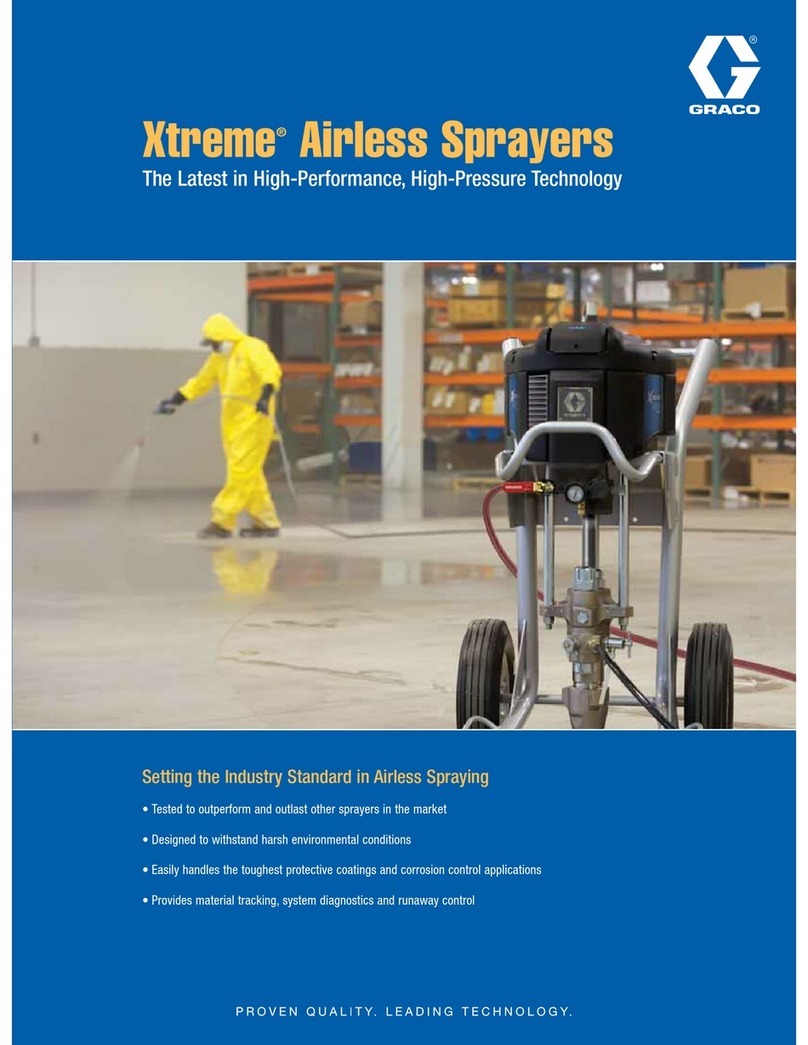

Graco Xtreme NXT User manual

Graco

Graco 24B327 User manual

Graco

Graco GM 3500 Operation manual

Graco

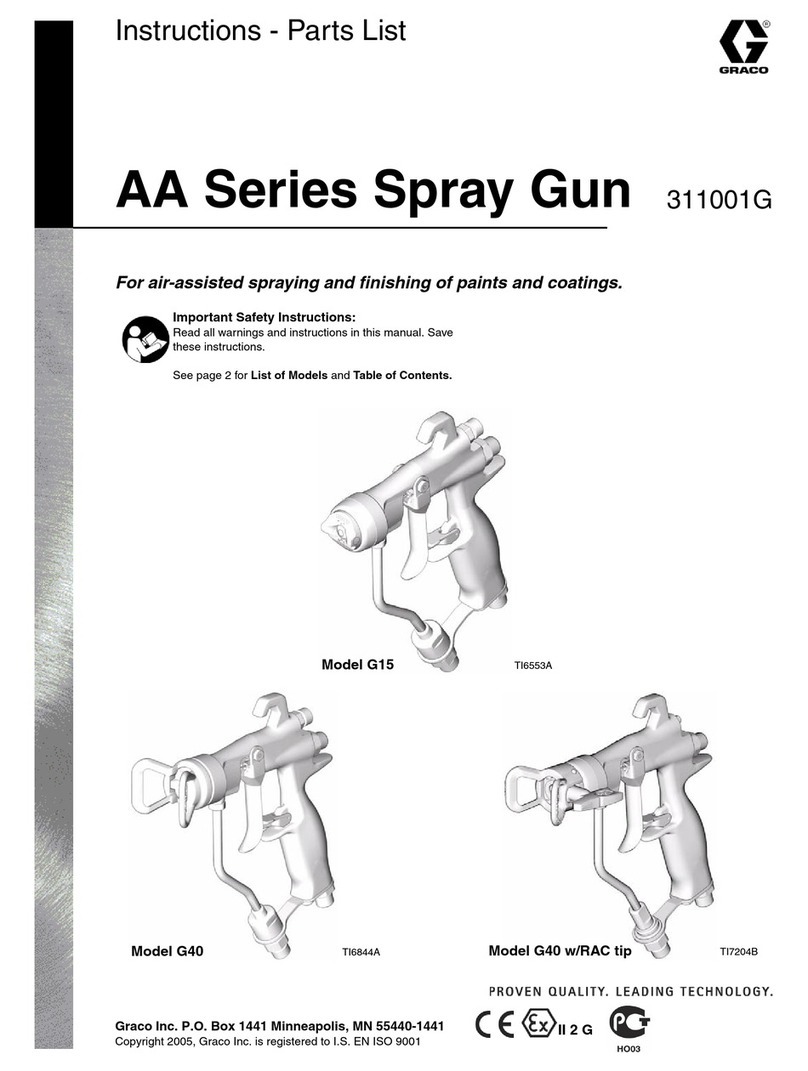

Graco 311001G Datasheet

Graco

Graco T-Max Applicator 256383 User manual

Graco

Graco REACTOR E-20 Assembly instructions

Graco

Graco LineLazer v 3900 User manual

Graco

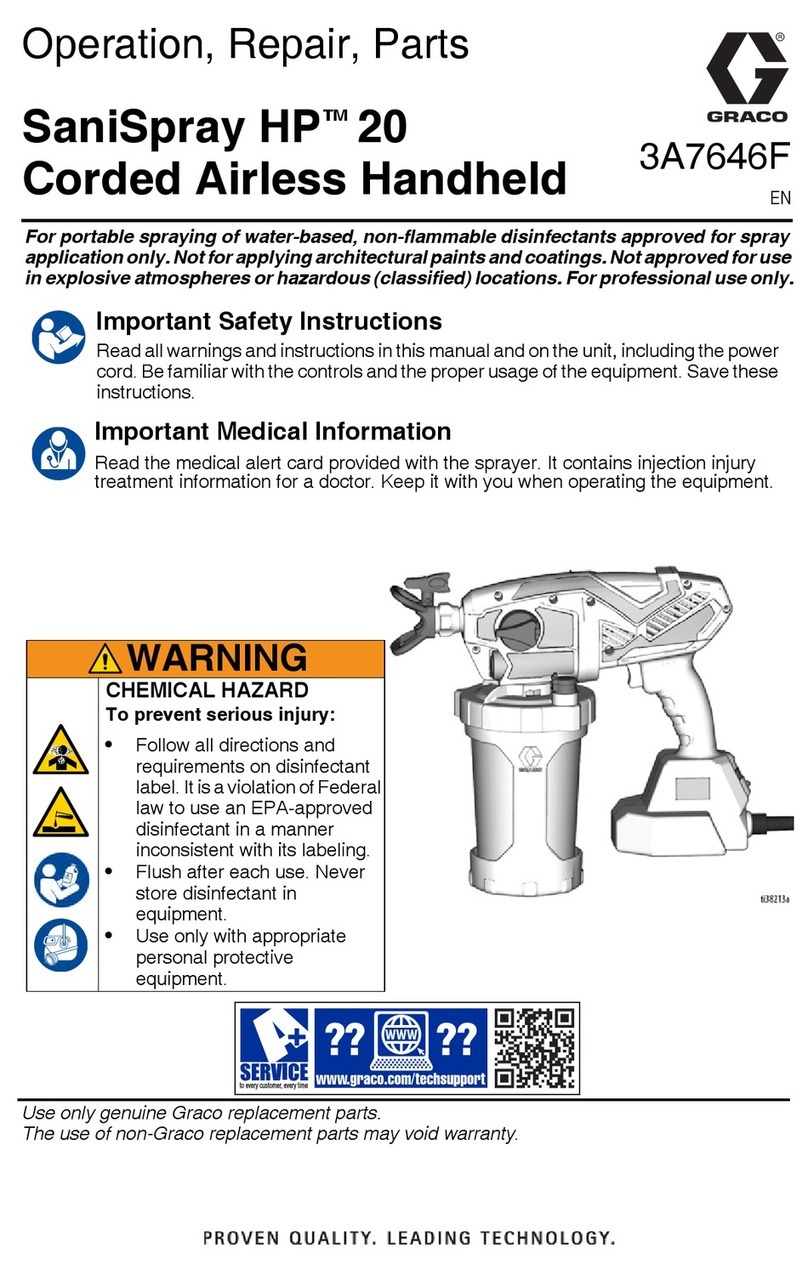

Graco SaniSpray HP 20 Use and care manual

Graco

Graco SG20 Parts list manual

Graco

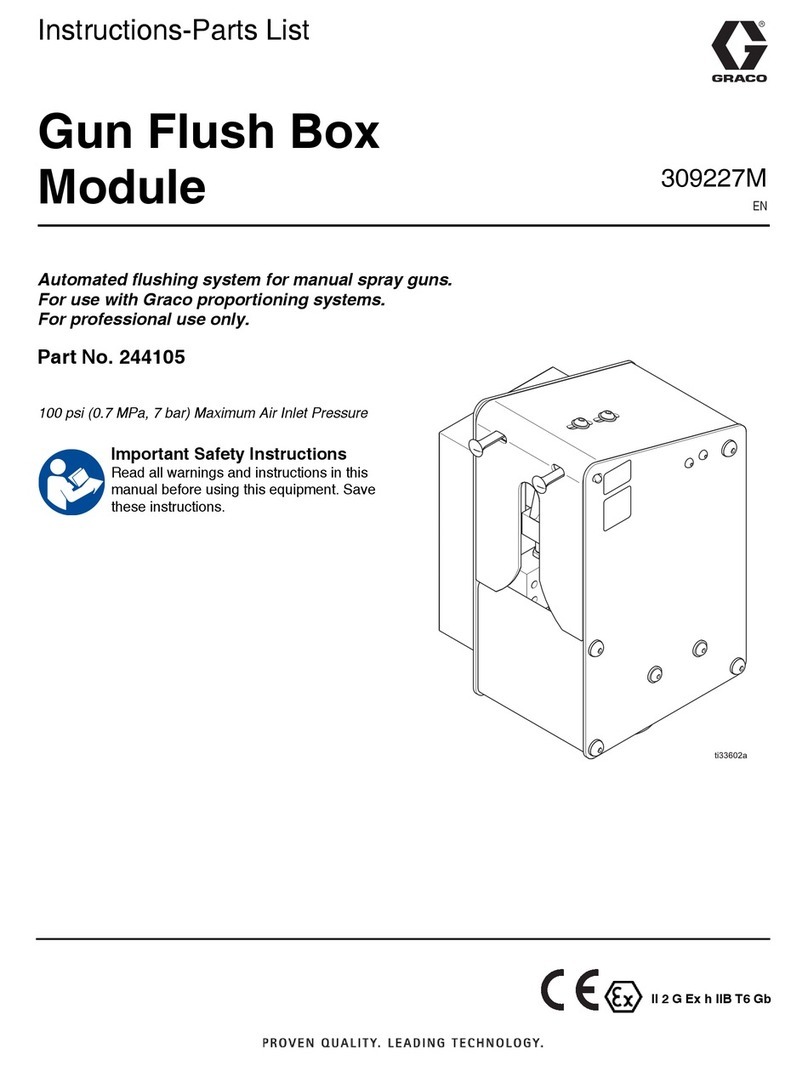

Graco Gun Flush Box Module Operation manual

Graco

Graco LineLazer V 250SPS User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual