7308717

Preparation

Grounding and Electrical Requirements

WARNING

Improper installation or alteration of the grounding

plug will result in a risk of electric shock, fire or

explosion that could cause serious injury or death.

Extension Cords

DUse only an extension cord with an undamaged,

3-prong plug.

DFor up to 25 ft (7.6 m) cord, use 3-wire, 12 AWG

(1.5 mm2) minimum.

DFor 25 to 50 ft (7.6 to 15.2 m) cords, use 3-wire,

10 AWG (2.5 mm2) minimum.

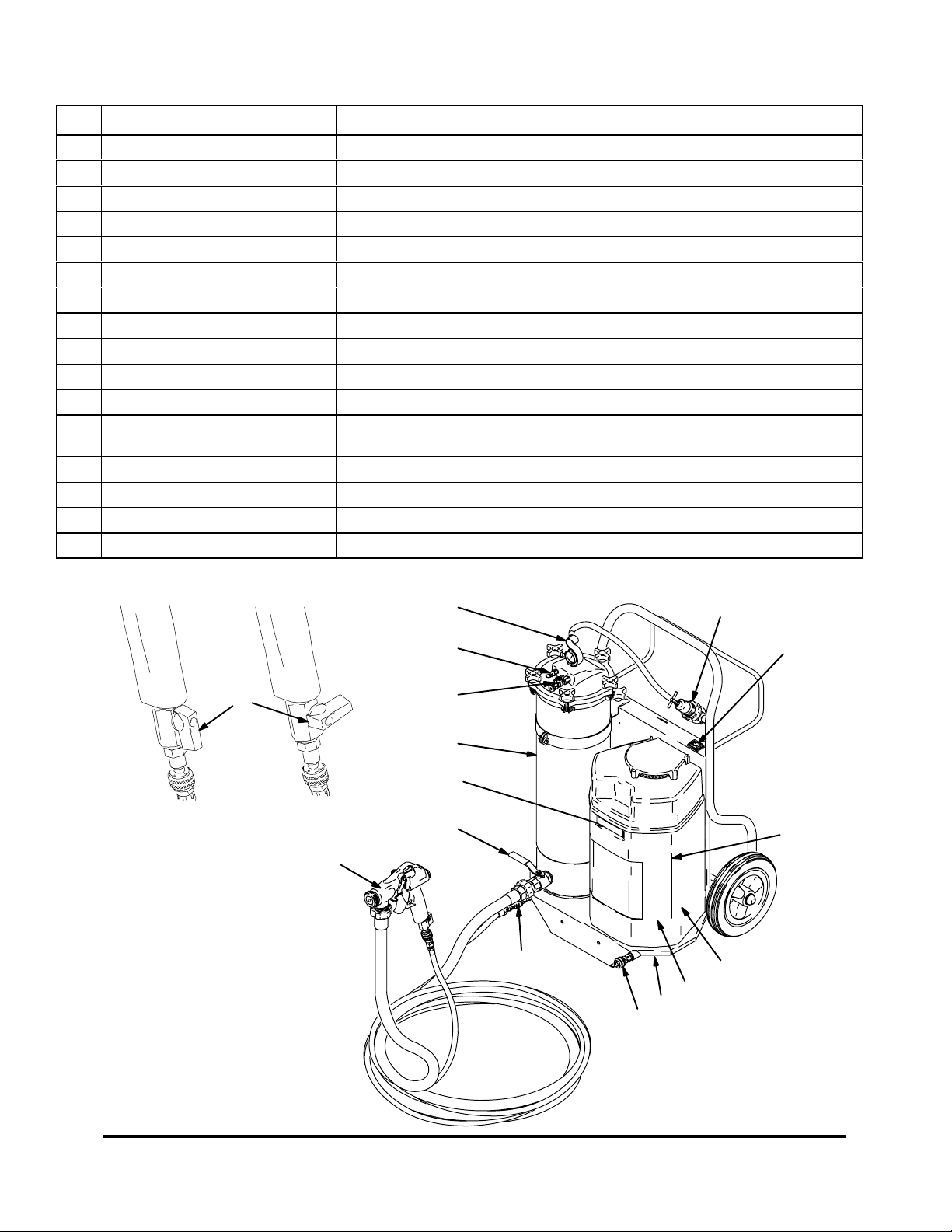

120V AC Systems

DThis equipment requires a 120V AC, 60 Hz, 15A

circuit with a grounding receptacle. See Fig. 4.

Fig. 4

grounding prong

grounded

outlets

DDo not alter the ground prong or use an adapter.

DA maximum length of 25 ft, 12 AWG or 50 ft,

10 AWG extension cord may be used.

240V AC Systems

DThis equipment requires a 240V AC, 50 Hz, 16A

circuit with a grounding receptacle. See Fig. 5.

Fig. 5

grounded

outlet

grounding prong 9248A

DDo not alter the ground prong or use an adapter.

DA maximum length of 8 m, 1.5 mm2or 15 m,

2.5 mm2extension cord may be used.

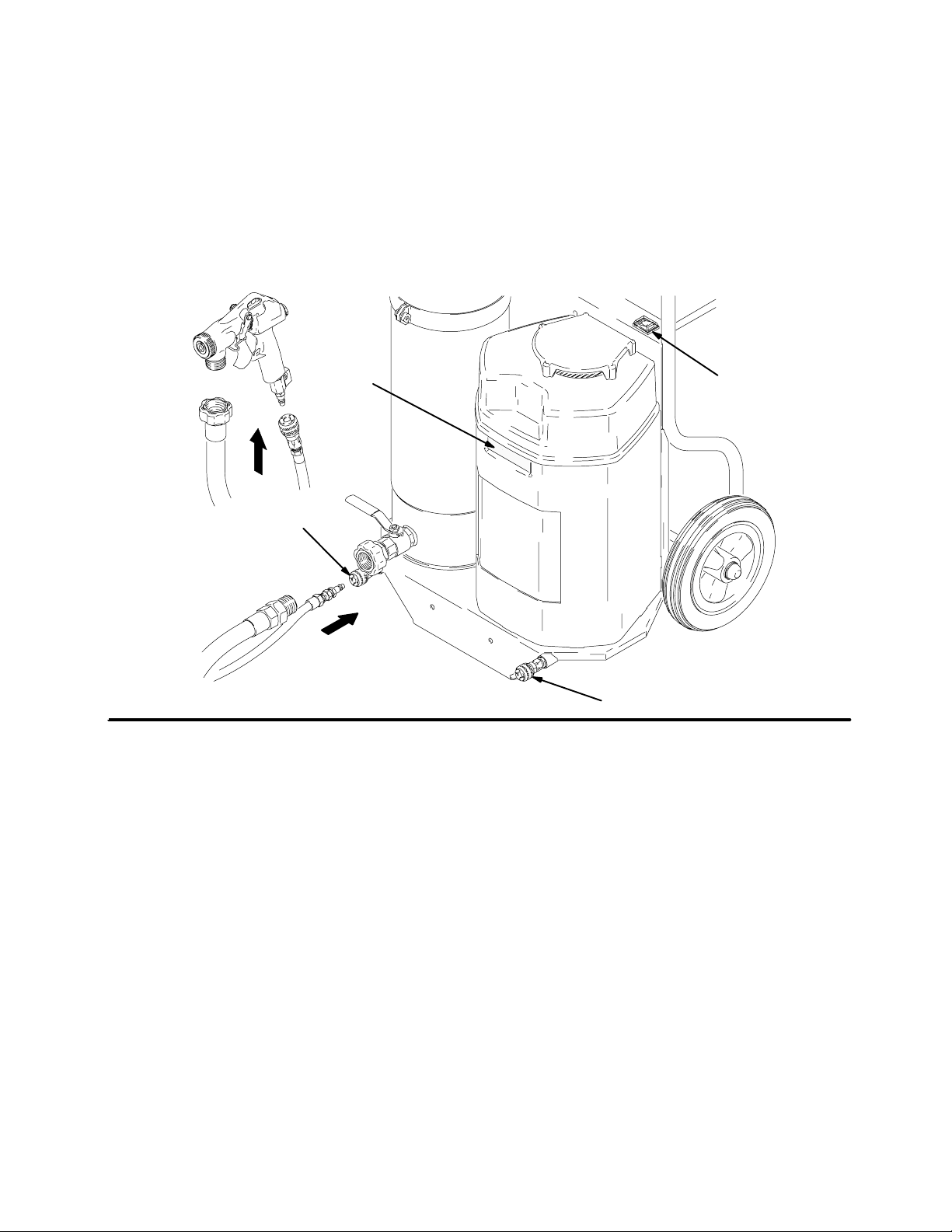

Hose Size and Lengths

The system comes with a hose set consisting of a 1 in.

ID x 25 ft (25 mm x 7.6 m) fluid hose and a 3/8 in. ID

air hose. The 1 in. hose set includes an adapter hose

between the gun and main hose. See Parts List on

page 23.

Do not use more than 75 ft (23 m) of fluid hose.

Auxiliary Air Compressor

An external air compressor may be connected

(adapter included) to the auxiliary air compressor port

(L) to supplement, or replace, the internal air

compressor of the TexSpray. This may be useful when

DAdditional air is needed to break up hard-to-spray

materials

DWhen the job site does not have the proper electric

service, but a gasoline-powered compressor is

available

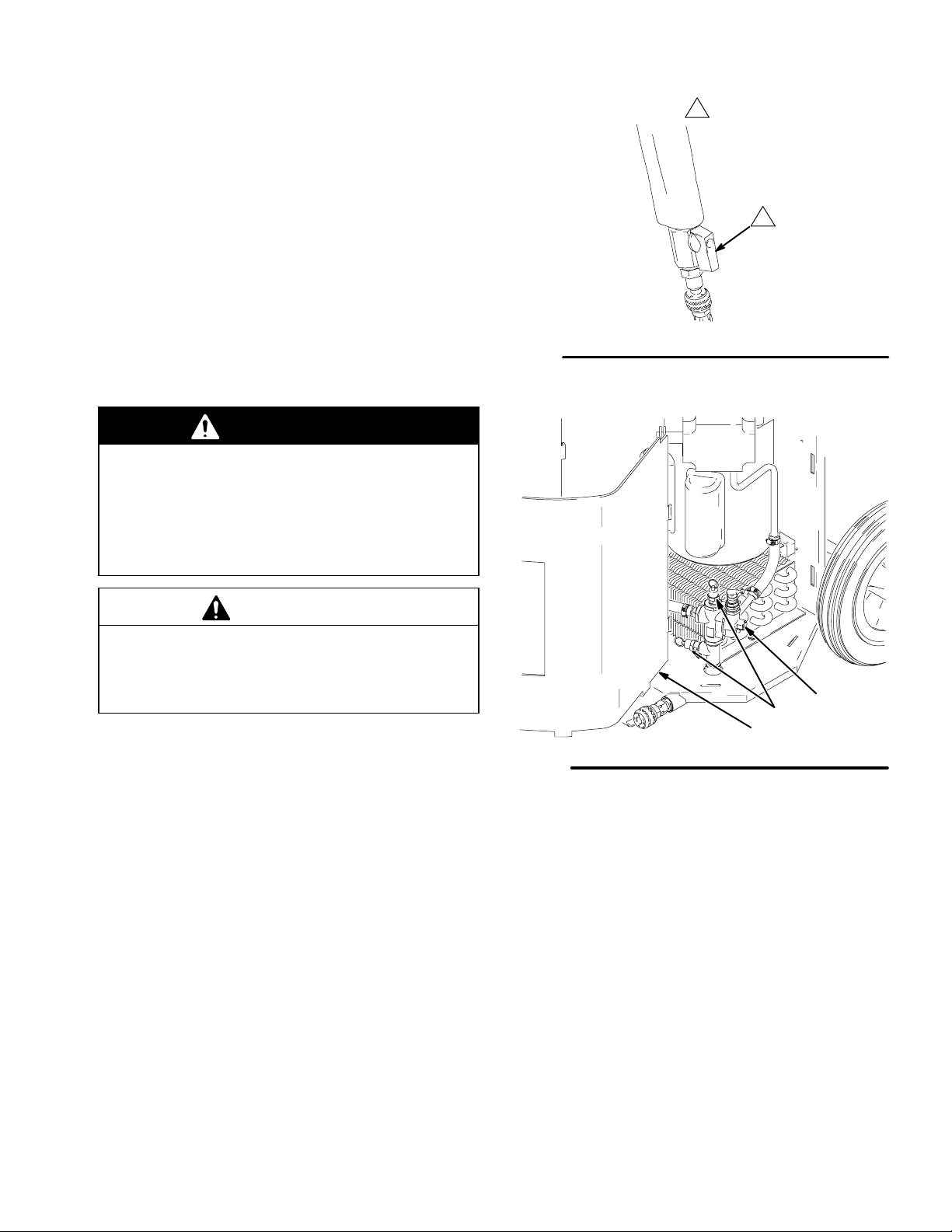

WARNING

Over pressurizing the system may cause compo-

nent rupture and resulting in serious injury.

To reduce the risk of over pressurizing the system, do

not use a compressor with an output pressure greater

than 100 psi (70 kPa, 7 bar), and/or with a delivery

greater than 6.8 scfm at 90 psi (0.19 m3/min. at

60.3 kPa, 6.3 bar).

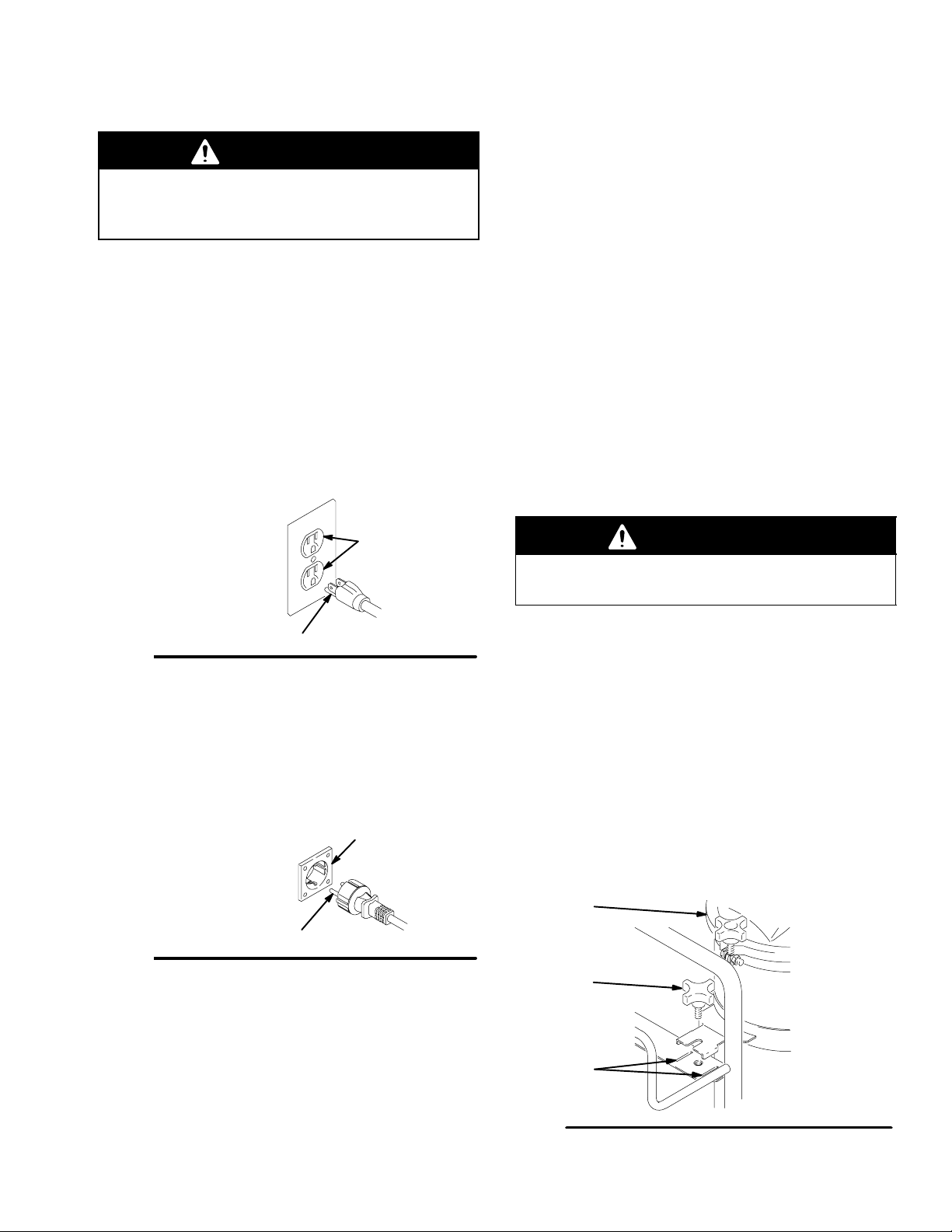

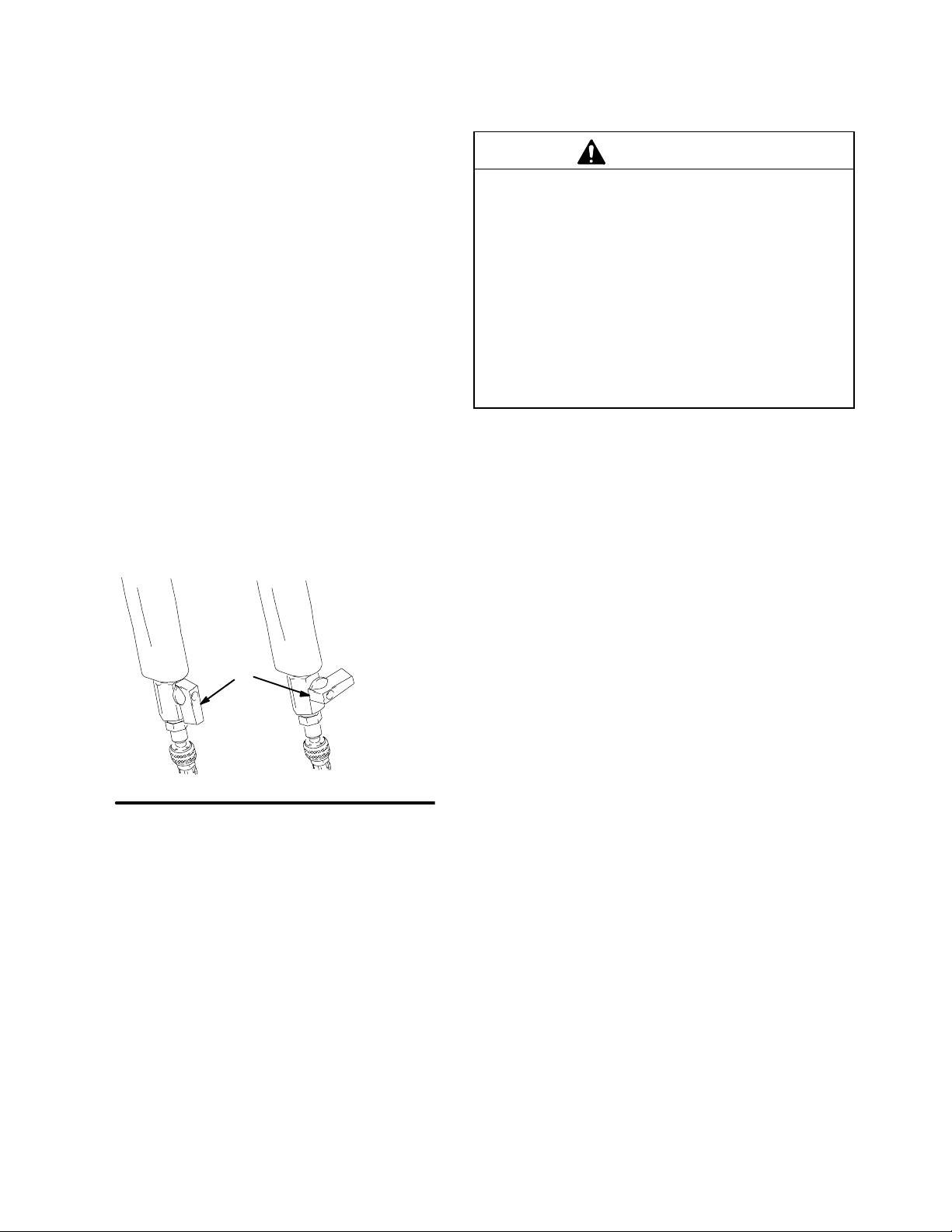

Removing and Installing the Pressure Pot

1. To remove the pressure pot (F), loosen the knob

(T) so that about 1 in. of the threads are showing.

Lift the pot off the unit. See Fig. 6.

2. To install the pressure pot, align bracket over slots

(S) and set it on the plastic base. Tighten the knob

(T). See Fig. 6.

Fig. 6

S

F

7124A

T