Installation

Installation Installation

Installation

General General

GeneralInformation Information

Information

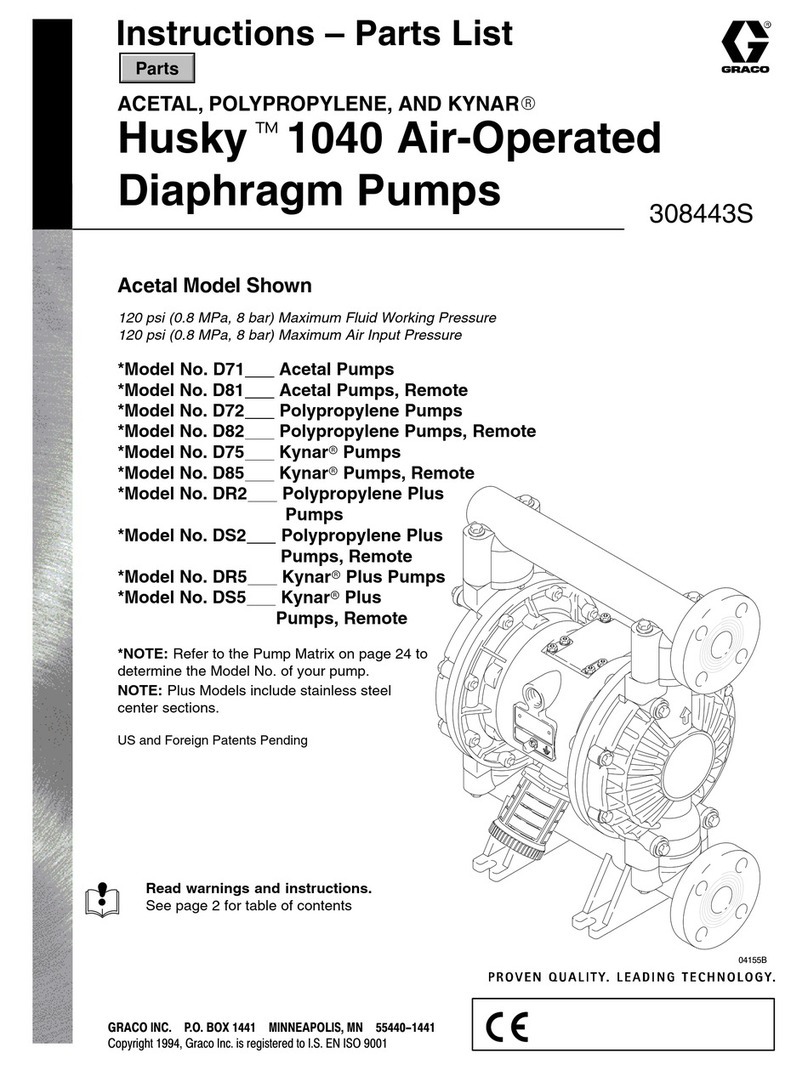

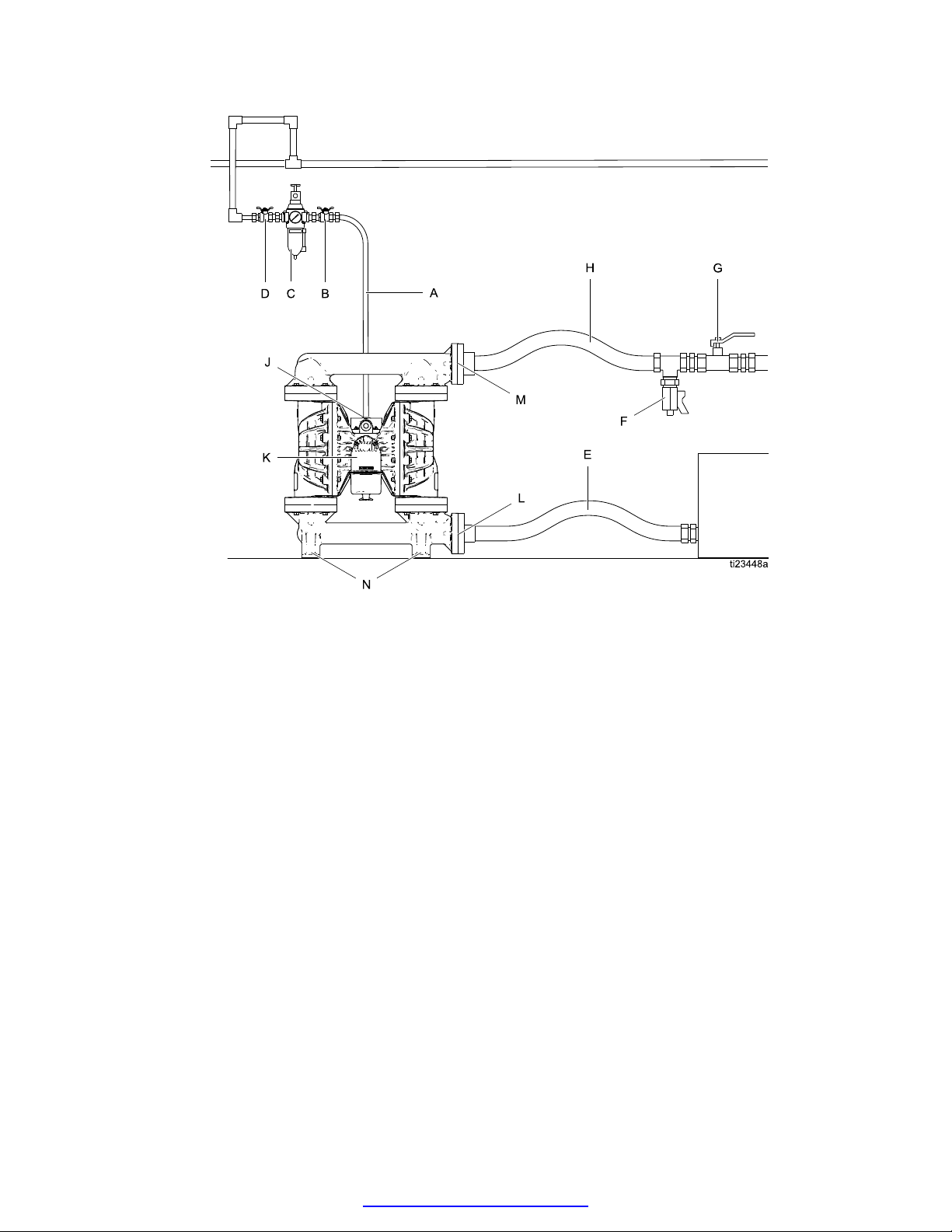

TheTypicalInstallationshownisonlyaguidefor

selectingandinstallingsystemcomponents.Contact

yourGracodistributorforassistanceinplanninga

systemtosuityourneeds.AlwaysuseGenuine

GracoPartsandaccessories.Besureallaccessories

areadequatelysizedandpressureratedtomeetthe

system’srequirements.

Referencelettersinthetext,forexample(A),referto

thecalloutsinthegures.

Variationsincolorbetweentheplasticcomponents

ofthispumparenormal.Colorvariationdoesnot

affecttheperformanceofthepump.

Tighten Tighten

TightenFasteners Fasteners

Fasteners

Beforemountingandusingthepumpforthersttime,

checkandretorqueallexternalfasteners.Follow

TorqueInstructions,page16,orseethetorque

tagonyourpump.Aftertherstdayofoperation,

retorquethefasteners.

Tips Tips

Tipsto to

toReduce Reduce

ReduceCavitation Cavitation

Cavitation

CavitationinanAODDpumpistheformationand

collapseofbubblesinthepumpedliquid.Frequent

orexcessivecavitationcancauseseriousdamage,

includingpittingandearlywearofuidchambers,

balls,andseats.Itmayresultinreducedefciencyof

thepump.Cavitationdamageandreducedefciency

bothresultinincreasedoperatingcosts.

Cavitationdependsonthevaporpressureofthe

pumpedliquid,thesystemsuctionpressure,andthe

velocitypressure.Itcanbereducedbychangingany

ofthesefactors.

1.Reducevaporpressure:Decreasethe

temperatureofthepumpedliquid.

2.Increasesuctionpressure:

a.Lowertheinstalledpositionofthepump

relativetotheliquidlevelinthesupply.

b.Reducethefrictionlengthofthesuction

piping.Rememberthatttingsaddfriction

lengthtothepiping.Reducethenumberof

ttingstoreducethefrictionlength.

c.Increasethesizeofthesuctionpiping.

NOTE: NOTE:

NOTE:Besuretheinletuidpressuredoesnot

exceed25%oftheoutletworkingpressure.

3.Reduceliquidvelocity:Slowthecyclicrateof

thepump.

Pumpedliquidviscosityisalsoveryimportantbut

normallyiscontrolledbyfactorsthatareprocess

dependentandcannotbechangedtoreduce

cavitation.Viscousliquidsaremoredifculttopump

andmorepronetocavitation.

Gracorecommendstakingalltheabovefactors

intoaccountinsystemdesign.Tomaintainpump

efciency,supplyonlyenoughairpressuretothe

pumptoachievetherequiredow.

Gracodistributorscansupplysitespecic

suggestionstoimprovepumpperformanceand

reduceoperatingcosts.

Mount Mount

MountThe The

ThePump Pump

Pump

Toavoidseriousinjuryordeathfromtoxicuidor

fumes:

•Ventilatetoaremotearea.Thepump

exhaustairmaycontaincontaminants.See

AirExhaustVentilation,page11.

•Nevermoveorliftapumpunderpressure.If

dropped,theuidsectionmayrupture.Always

followthePressureReliefProcedure,page14,

beforemovingorliftingthepump.

1.Besurethemountingsurfacecansupportthe

weightofthepump,hoses,andaccessories,as

wellasthestresscausedduringoperation.

2.Forallmountings,besurethepumpissecured

withscrewsthroughthemountingfeet.

3.Makesurethesurfaceisatandthatthepump

doesn’twobble.

4.Foreaseofoperationandservice,mountthe

pumpsoairvalve,airinlet,uidinletanduid

outletportsareeasilyaccessible.

5.ProlongedexposuretoUVradiationwilldegrade

naturalpolypropylenecomponentsofthepumps.

Topreventpotentialinjuryorequipmentdamage,

donotexposepumportheplasticcomponents

todirectsunlightforprolongedperiods.

8 3A2578E