NOTE: In speed clock operation mode CL 1 –CL 8 (see chapter 3) the input of the

lubricant feeding quantity is made in g/km (grams per kilometer of thread)

and not in g/min (grams per minute).

Calculation Example ONLY for setting CL 1 or CL 8

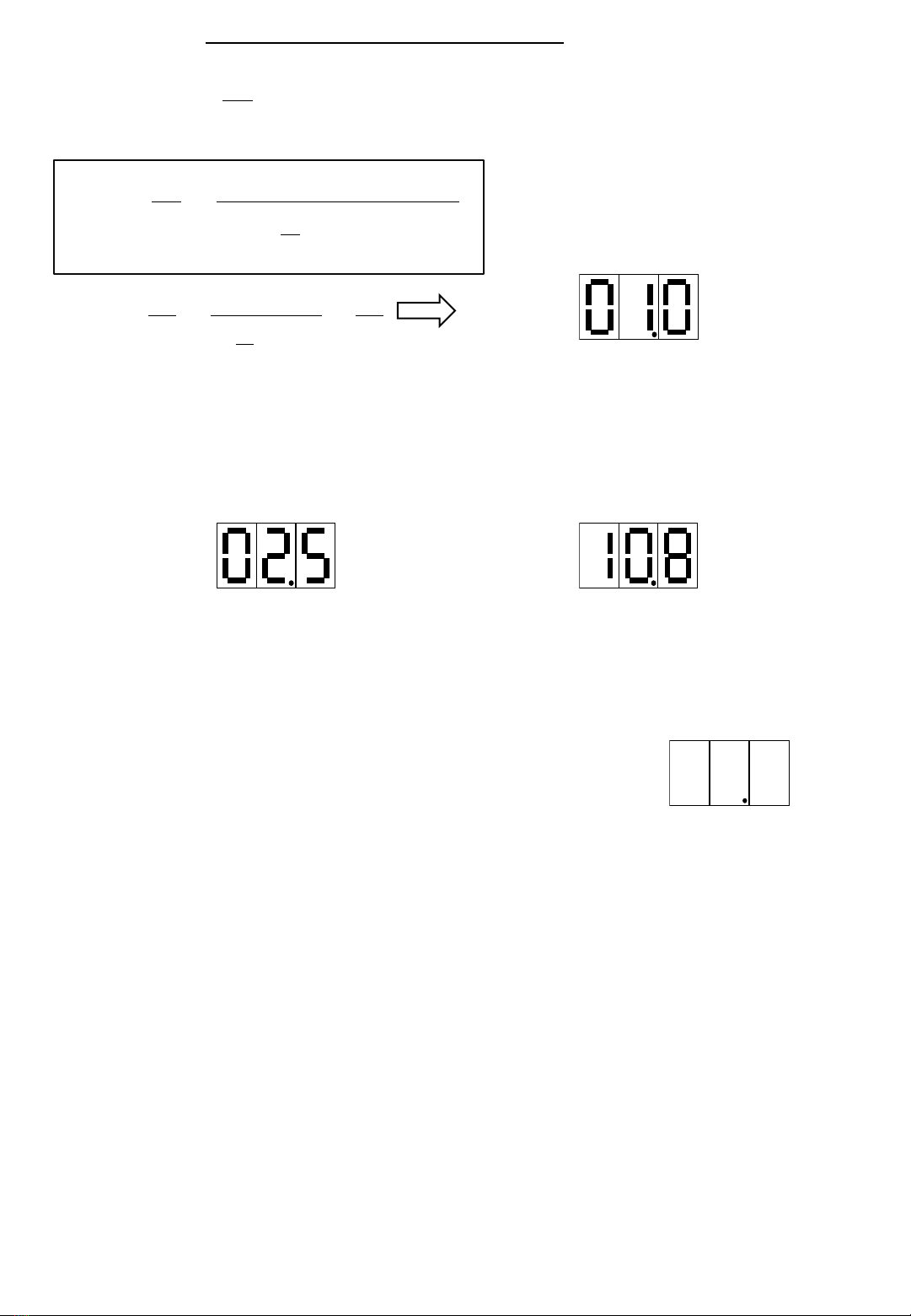

2.3 Setting of output

The output can now be adjusted using the keys 1, 2, 3. Each digit must be set separately.

With each press on the key, the corresponding number increases by 1.

Once the number 9 is passed, the unit return to zero.

%lub

1000%

activity

g

m

Nm

uptake

km

g

Setting

eff

km

g

g

m

km

g

Setting 1

%10035

1000%5.3

to set

To change for example to

press the key 1once, the key 2eight times and the key 3three times.

Thus the output of 2.5 g/min has been changed to 10.8 g/min. This setting

remains the same until the next adjustment, even if the device is disconnected in

the meantime.

2.4 Turn on/off

With the I/O key the pump can be turned off. The display indicates:

The luminous decimal point of the second digit indicates that the pump is in off mode and will

not meter even if the winding machine is working.

By another press on the I/O key the pump is changed to on mode and the display shows the

value which was indicated before. The applicator is still hot.

2.5 Applicator Temperature

The current applicator temperature can be displayed by pressing MODE key at short term. In this

mode, the display shows degree sign (°) plus the current applicator temperature in degrees Celsius.

In order to exit applicator temperature display mode, press the MODE key once more.

This mode just displays the current applicator temperature.

The applicator temperature can be changed within a range of 20 to 80 degrees Celsius by modifying

the AtP Applicator Temperature Value in the configuration menu (see chapter 3.)

The standard setting is 60 degrees Celsius.

Instruction Manual GRAF SINGLE LUB 2 / Version 4.0 –05.2020 7