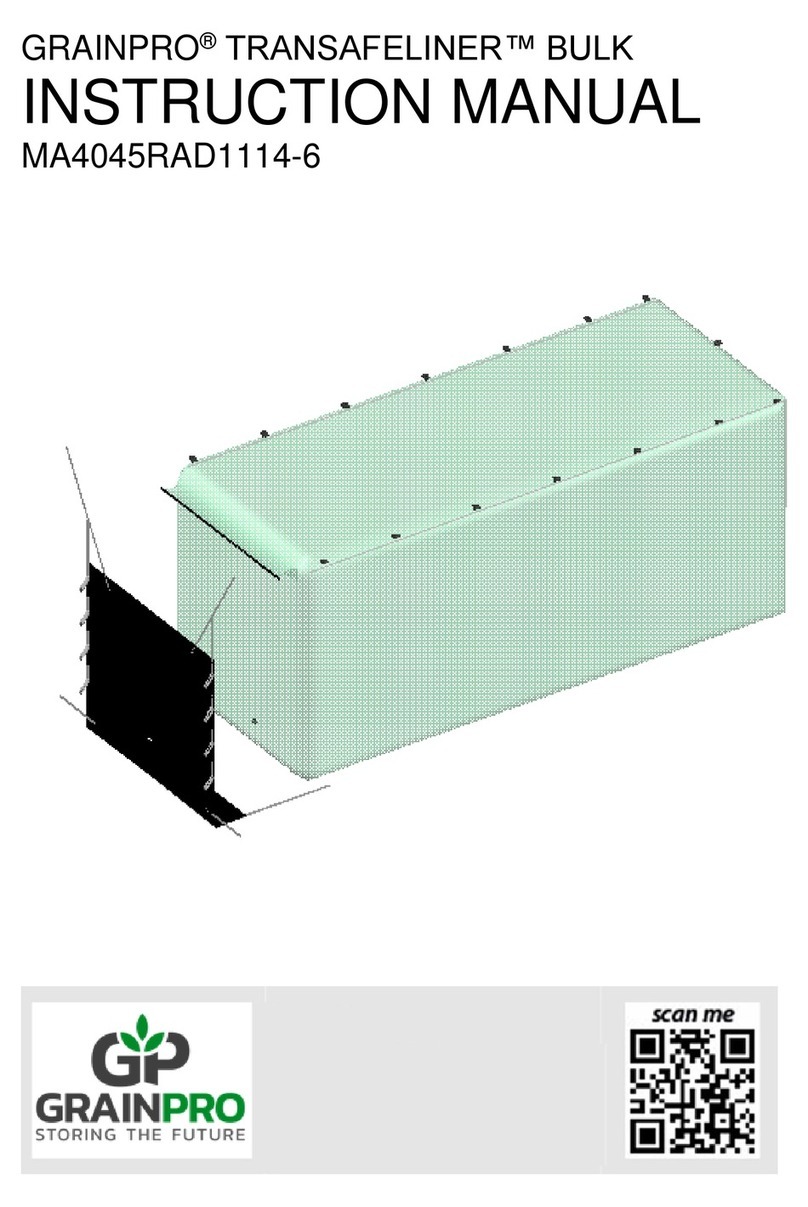

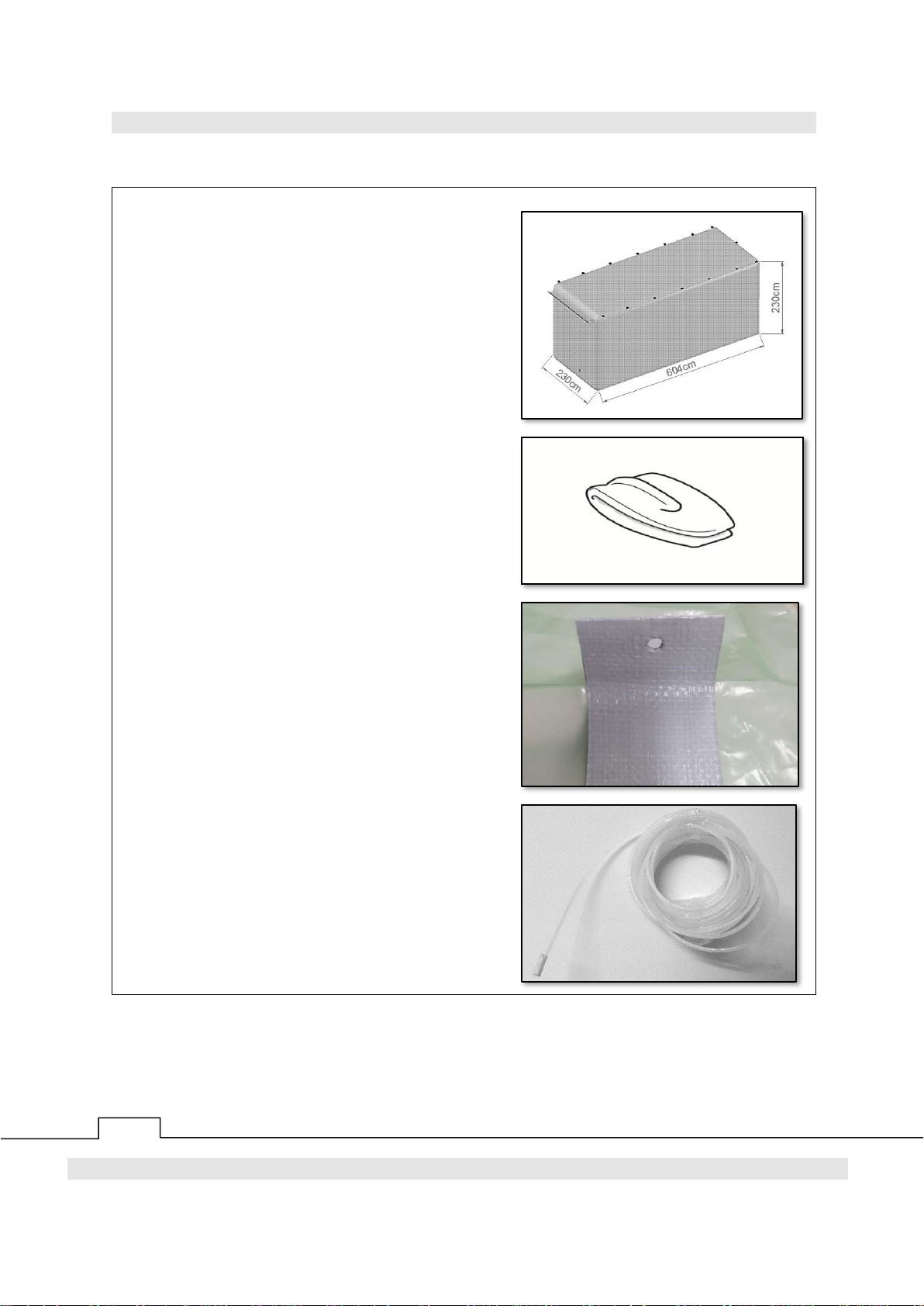

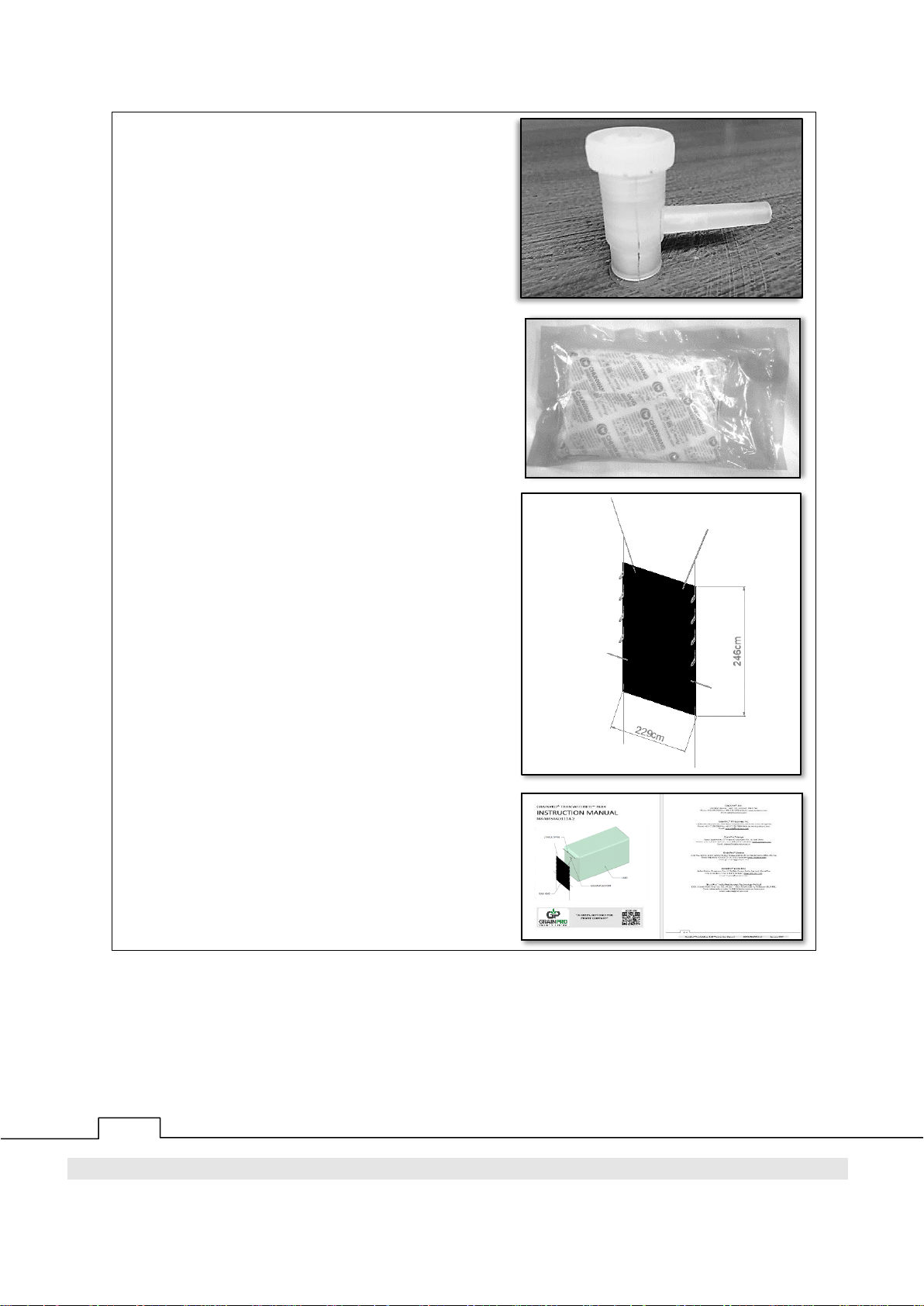

The GrainPro®TranSafelinerTM Bulk (TSL Bulk) is designed to protect dry agricultural commodities

shipped in bulk inside an ISO shipping container. It is made of Ultra Hermetic PE with barrier layer. It

has superior gas and moisture resistant properties to restrict the entry of moist ambient which reduces

risks due to condensation, mold growth, and insect infestation. As a result, the TSL Bulk preserves the

quality of dried agricultural commodities and prevents postharvest losses while in transit. It also has a

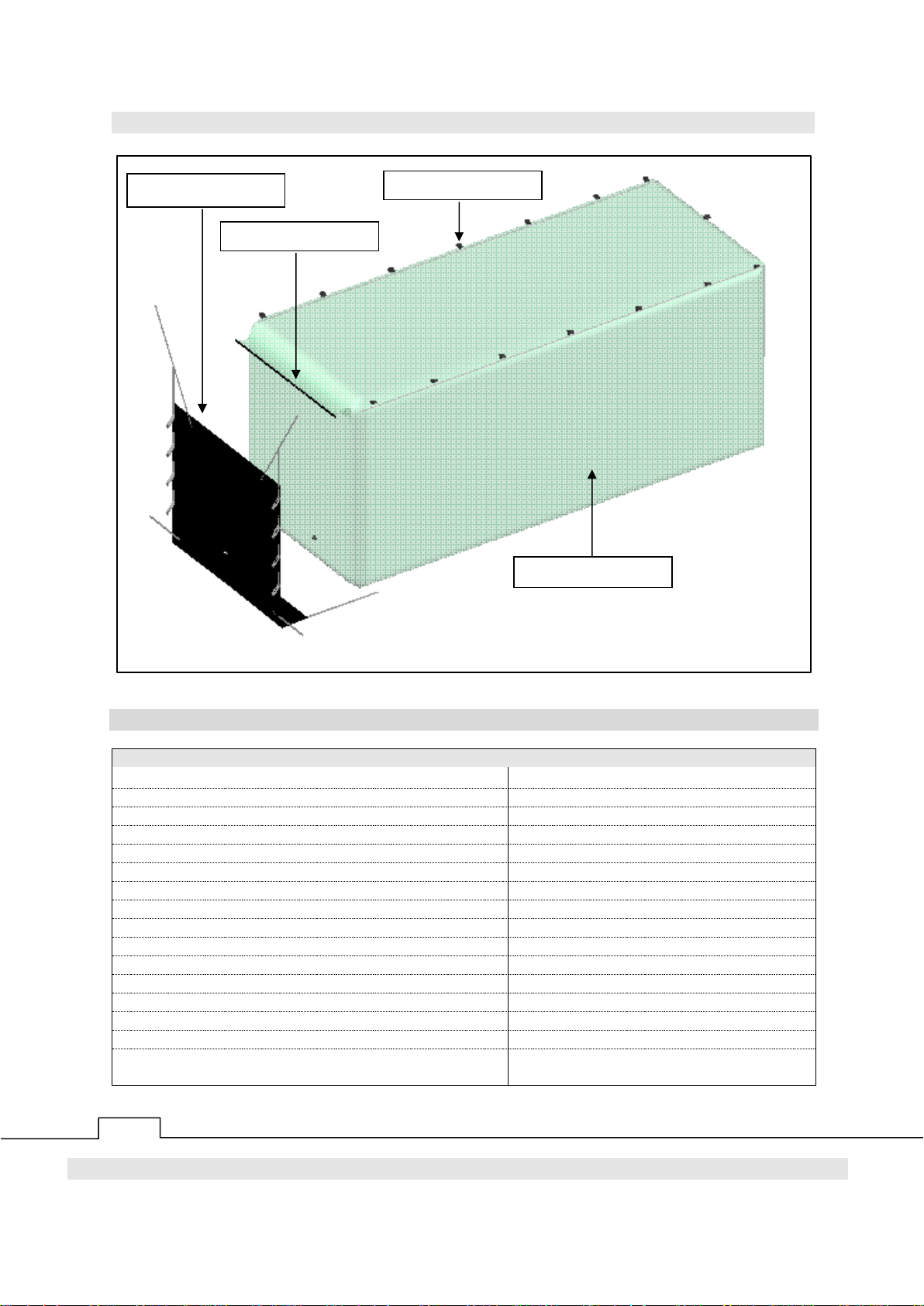

GHF inlet port for fumigation. The TSL Bulk consists of Ultra-Hermetic liner and bulkhead. Using nylon

rope and pre-installed tape, the liner can be easily hung inside the container. To support the commodity’s

lateral force, a strong woven polyethylene bulkhead is fitted into the container’s doorway using straps

and 1.5” steel tubes positioned horizontally and anchored into the groove of the container’s wall. Loading

the single trip TSL Bulk can be done using grain augers or screw conveyors (with TSL blower) which

can be fitted in the liner’s resealable loading port. Unloading of the TSL Bulk is best done by self-

discharging or by tilt-trailer where unloading can be done by slitting the bottom portion of the TSL Bulk

and tilting the shipping container.

1.1. FEATURES:

1.1.1. “Green” fumigation technology acknowledged as organic fumigation using CO2

1.1.2. Preserves quality and minimizes damage to dry agricultural commodities in transit

1.1.3. A “green” technology for the transport and organic preservation of dry agricultural commodities

(certified safe for organic grain storage)

1.1.4. Minimizes condensation, inhibits/control mold growth and infestation

1.1.5. Easy to install in a container van using nylon ropes

1.1.6. Two options in installing the bulkhead (straps or rigid bars)

1.1.7. Maximizes the volumetric capacity of shipping container

1.1.8. Reduces packaging cost vs. bagged commodities

1.1.9. Reduces labor cost.

1.1.10. Prevents grain contamination

1.2. PRODUCT GUARANTEE:

1.2.1. In accordance with the terms and conditions herewith, GrainPro, Inc. fully guarantees the quality

of this product if the product is used according to the instructions in this operator’s manual.

1.2.2. Please read and understand the manual thoroughly before using the TSL Bulk.

1.3. COMMENTS, COMPLAINTS, AND/OR CLARIFICATIONS:

1.3.1. Please contact customercare@grainpro.com,

we shall be glad to answer any of your questions.