TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................................................... 4

2. CHECKLIST.................................................................................................................................... 5

3. COMPONENTS ............................................................................................................................. 6

4. SPECIFICATIONS........................................................................................................................... 6

5. WARNINGS………………………………………………………………………………………………………………………………7

6. RECOMMENDED MAXIMUM MOISTURE CONTENT FOR SAFE STORAGE…………………………………7

7. INSTALLATION.............................................................................................................................. 7

Site selection .......................................................................................................................... 8

Termite Control………………………………………………………………………………………………………………….8

Rodent Control………………………………………………………………………………………………………………….9

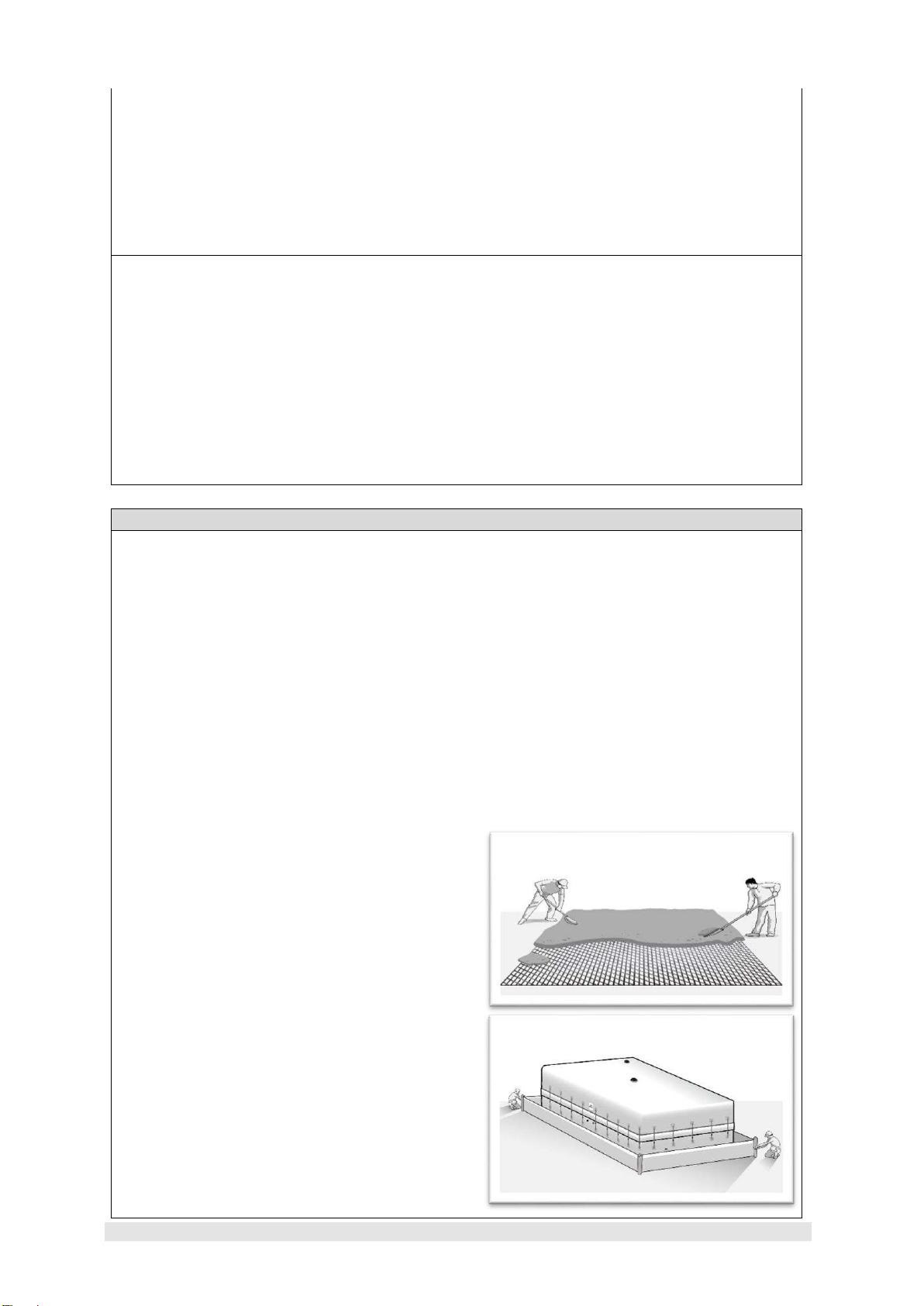

Loading ................................................................................................................................. 10

Zipping.................................................................................................................................. 11

Installation of rodent guard (RG) ......................................................................................... 12

Outdoor installation ............................................................................................................. 13

Monitoring the oxygen level ................................................................................................ 13

Dismantling........................................................................................................................... 14

8. Preventing Condensation………………………………………………………………………………………………………14

Why does condensation occur ............................................................................................. 14

Moisture content (MC) requirement for safe storage ......................................................... 14

9. Maintenance and Care………………………………………………………………………………………………………….15

Regular Examination ............................................................................................................ 15

Repairing punctures and other damages ............................................................................. 15

Recommended weekly monitoring ...................................................................................... 15

Cleaning................................................................................................................................ 16

Safekeeping .......................................................................................................................... 16

Prohibited item not allowed to ship..................................................................................... 16

Recycling............................................................................................................................... 16

10. FREQUENTLY ASKED QUESTIONS AND ANSWERS………………………………………………………………….16

11. WARRANTY CLAUSE………………………………………………………………………………………………………………18