GrainPro® TranSafeliner™ Instruction Manual (Vacuum Method) MA4081RAD1219-01

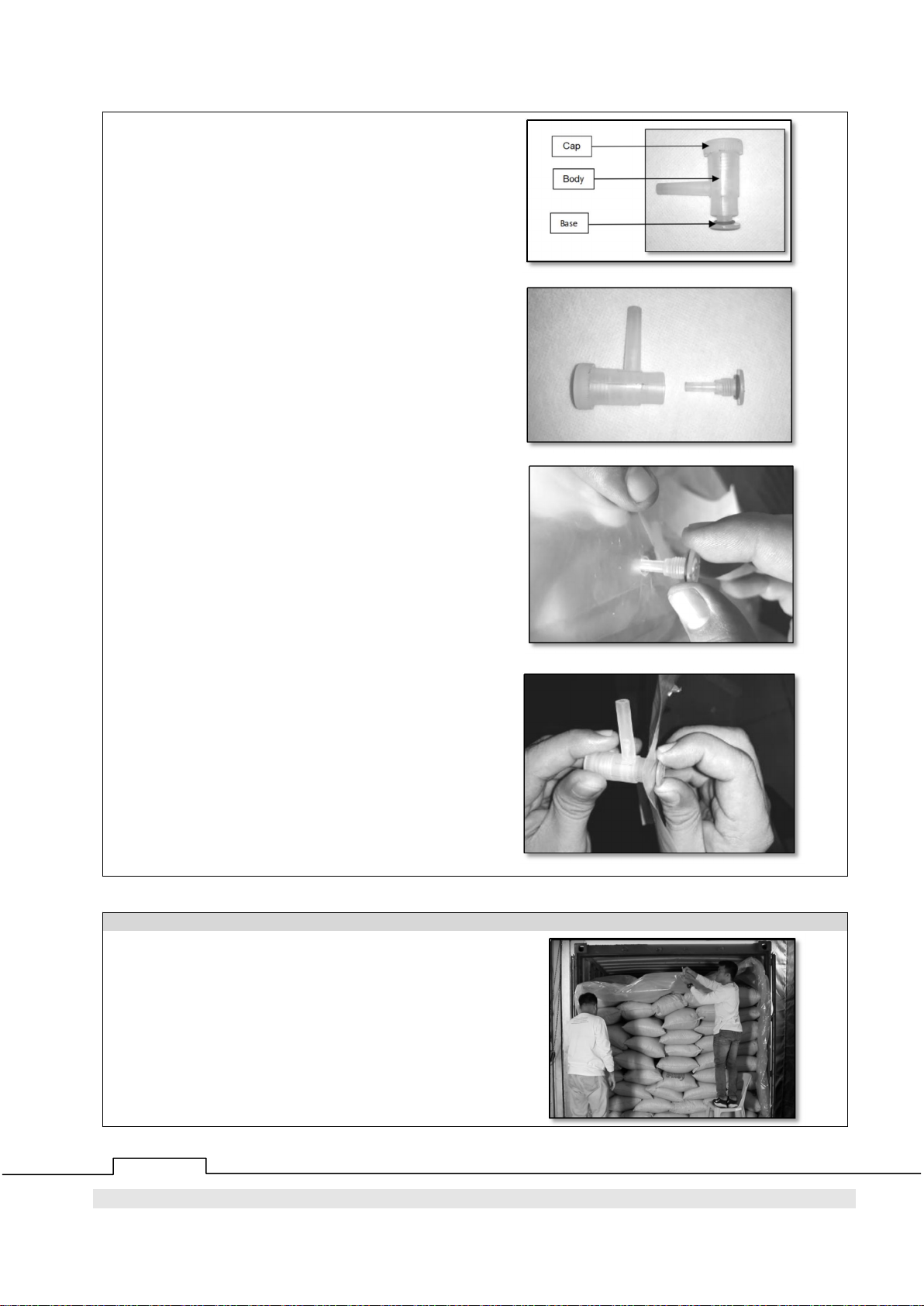

3.5.5. Twist the plastic valve cap to close after

taking the readings.

3.6. USING CARBON DIOXIDE ANALYZER FOR MONITORING (WITHOUT CO2FLUSHING) -

The GrainPro CO2analyzer uses a non-dispersive infrared radiation (NDIR) sensor for the detection of

carbon dioxide. When a sensor encounters a target gas, voltage signal is generated in proportion to the

gas concentration. This voltage signal is amplified, digitized and displayed on the instrument’s OLED

display.

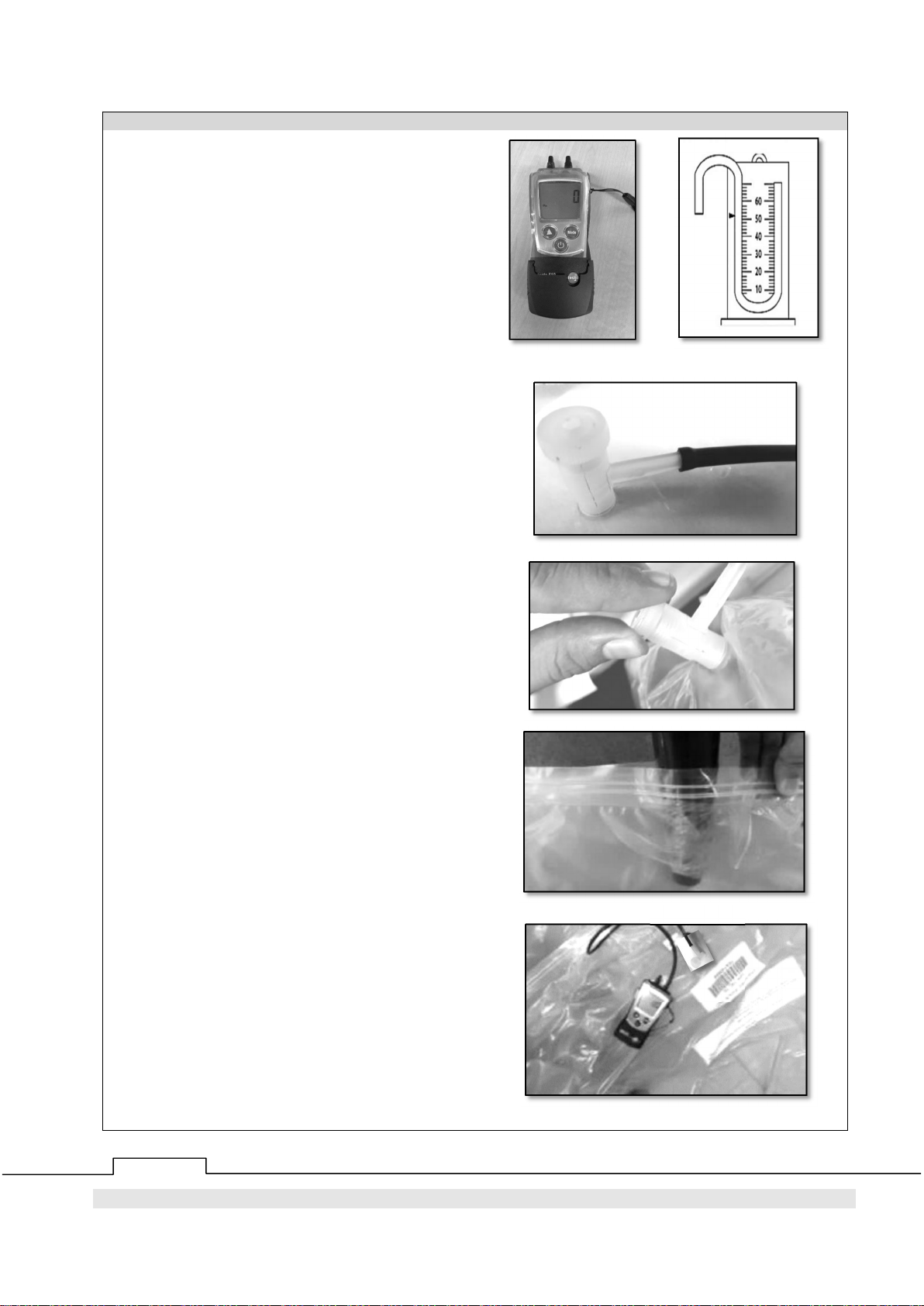

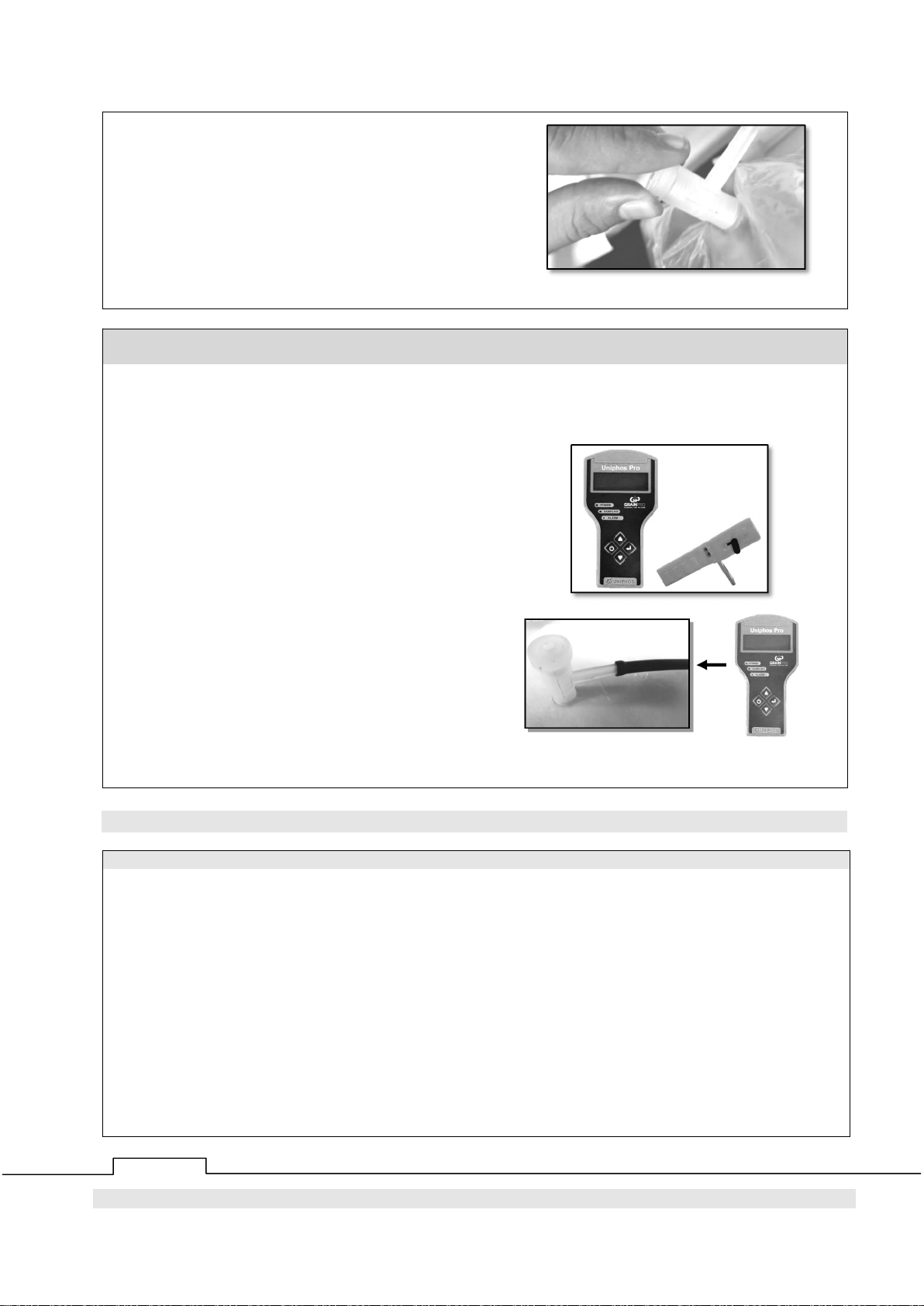

3.6.1. When taking the carbon dioxide reading,

connect the flexible adapter hose into the

plastic valve.

3.6.2. Using the analyzer, carbon dioxide level can

be checked through the plastic valve with

flexible adapter hose before unloading.

Increased carbon dioxide level indicates

absence of any source of leaks from

punctures, holes or damages. CO2level of

ambient air is 0.04%.

3.6.3. Monitoring of carbon dioxide level is recommended to ensure control of insect infestation. Details of

using CO2analyzer are discussed in the analyzer’s instruction manual.

4.1.1. Carbon dioxide does not support life. It can act as a simple asphyxiant by diluting the concentration

of oxygen in air below the levels necessary to support life. As it is heavier than air it will tend to

concentrate at lower levels.

4.1.2. Avoid breathing gas. Do not get in eyes, on skin, or on clothing. Wear leather safety gloves and

safety shoes when handling cylinders.

4.1.3. Protect cylinders from physical damage. Do not drag, roll, slide or drop. While moving cylinder,

always keep the removable valve cover in place. Never attempt to lift a cylinder by its cap; the cap is

intended solely to protect the valve. When moving cylinders, even for short distances, use a cart

(trolley, hand truck, etc.) designed to transport cylinders.

4.1.4. Never insert an object (e.g., wrench, screwdriver, and pry bar) into cap openings; doing so may

damage the valve and cause a leak. Use an adjustable strap wrench to remove over-tight or rusted

caps. Slowly open the valve. If the valve is hard to open, discontinue use and contact your supplier.

4.1.5. Close the cylinder valve after each use; keep closed even when empty.

4.1.6. Never apply flame or localized heat directly to any part of the cylinder. High temperatures may

damage the cylinder and could cause the pressure relief device to fail.