These products have been designed, constructed and built to minimize the time which the installer must use

before and after connecting them to the remote CO2 –installation. On cabinets referred to as IC, with a built-

in controller (either Danfoss AKCC 550A or Carel MPXpro), every electrical component is already connected

to the controller and the controller is configured accordingly. All controller parameter setups have been made

in cooperation with the two controller manufacturers (Danfoss and Carel), in order to make sure that the

cabinet will run when connected. There might of cause be settings which need to be changed/adapted in

order to optimize performance according to the remote system.

A few examples:

Solid door cabinets are delivered with auniversal set pointrange +12to -25°C, whichmeans that thecabinets

can be installed as a fridge or as a freezer. The reason for this is that all solid door cabinets are delivered as

a freezer configuration, including electrical defrost heater, door frame heater etc. for maximum flexibility

during installation.

If the cabinet is to run as a refrigerator it will most likely be connected to a remote system which will run a

suction pressure no lower than -10°C (often even higher). in this case it is recommendable to raise the

minimum allowed set point to approx. +2°C. which does mean that the adjustment range will be +2 to +12°C.

If the same universal cabinet is to run as a freezer, connected to a remote freeze system, the range should

be narrowed to e.g. -10 to -22°C or similar, to suite the settings of the remote system.

The difference between controller minimum setpoint temperature and the minimum suction pressure should

never be less than 7K.

IMPORTANT!

People installing these products, should have the right skill level.

This does relate to all aspects. (physical installation as well as adapting the controller settings of the

chosen controller, in order to avoid problems or potentially dangerous situations)

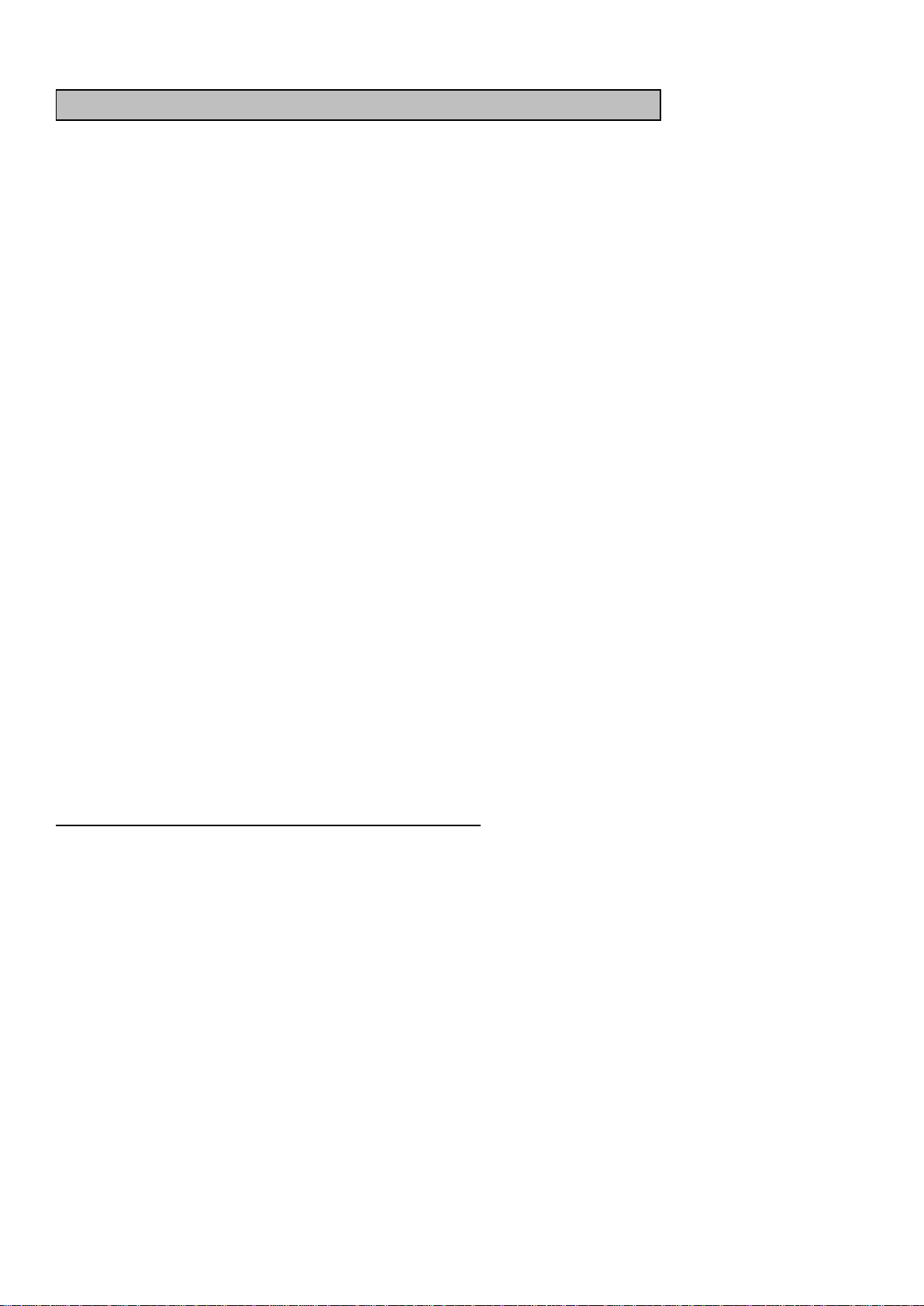

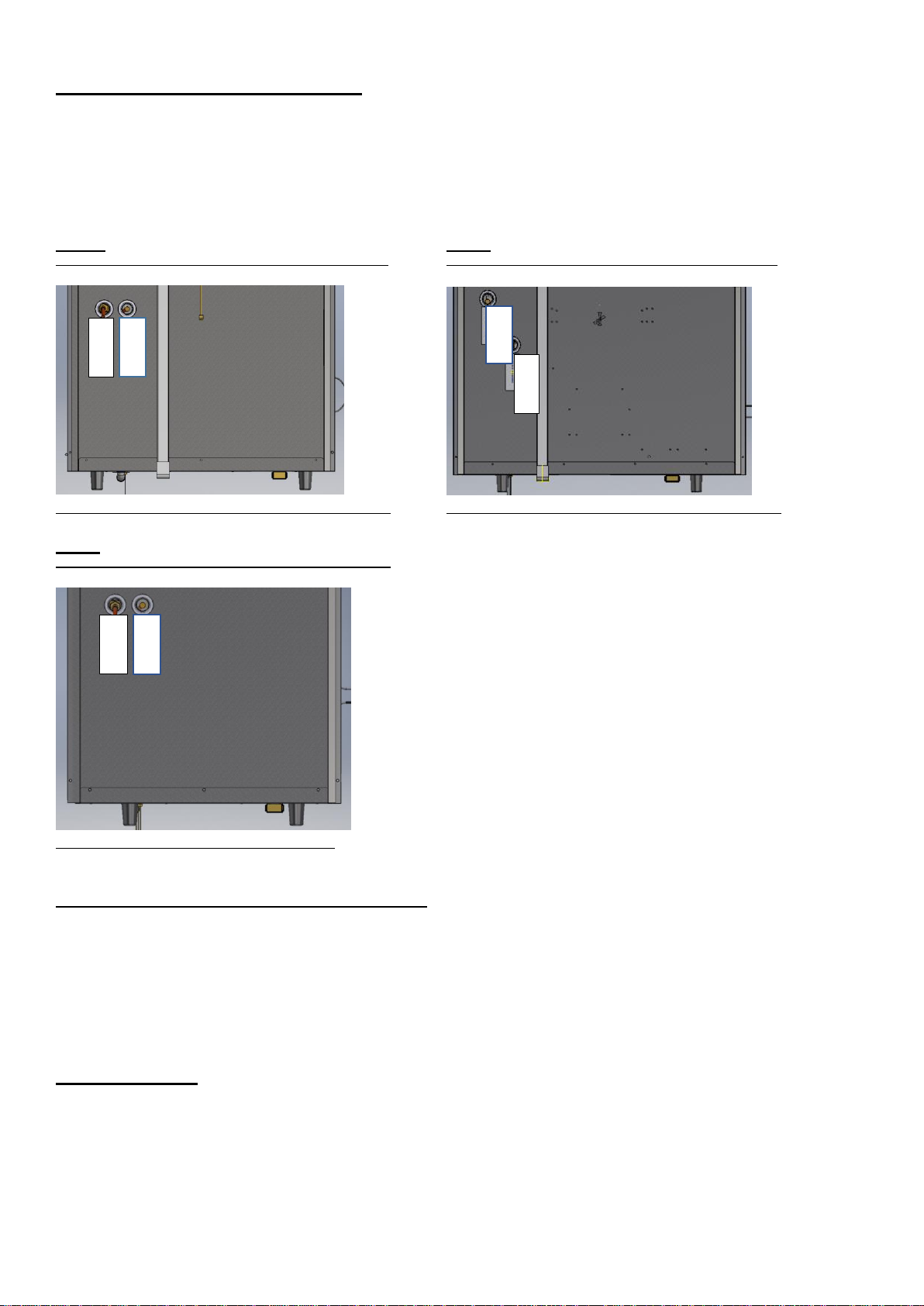

Always make sure that the cabinet is properly leveled when positioned on the installation location.

This should be done prior to connecting the pipe work to the remote CO2 system

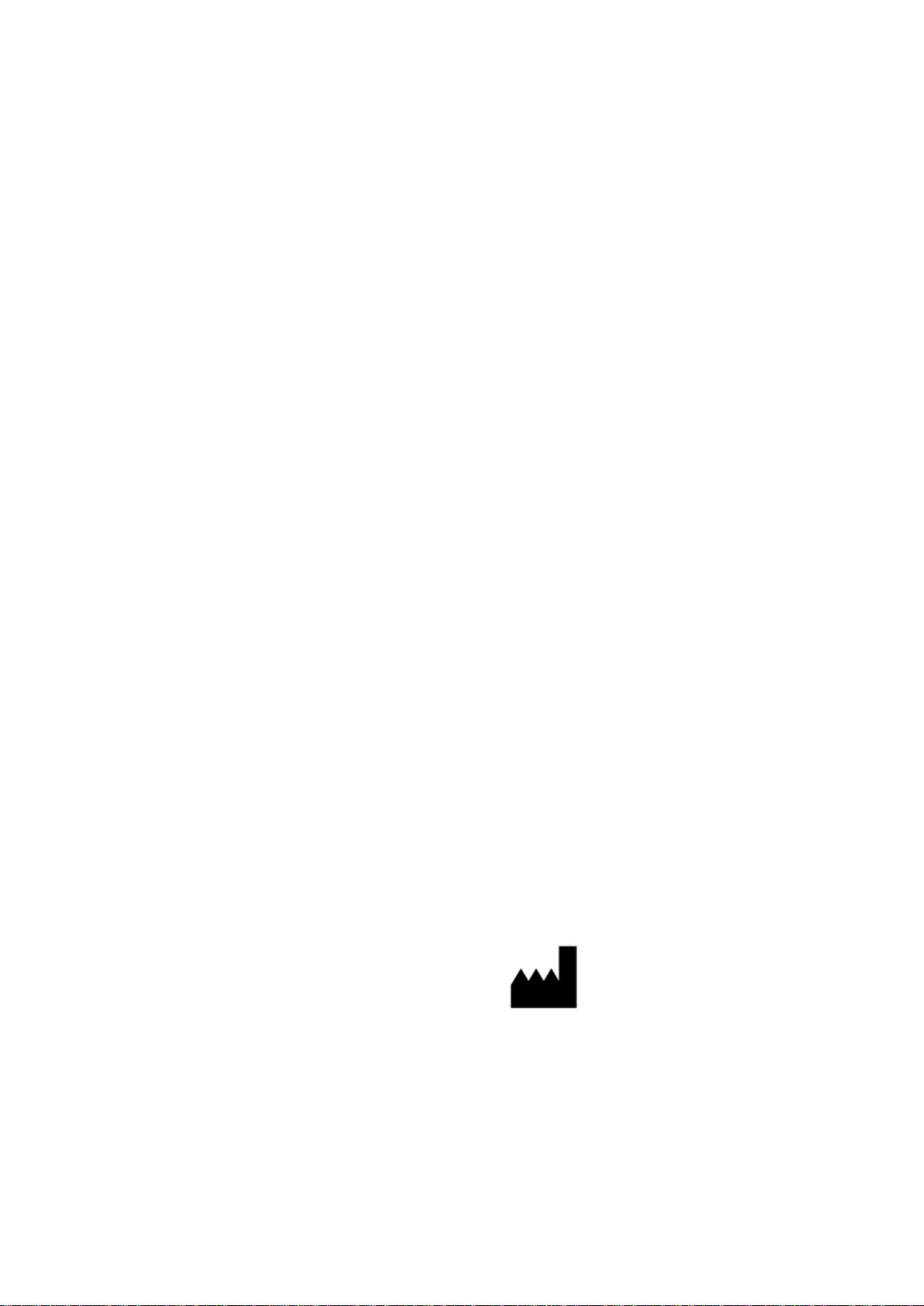

Commonly used parts on all IC upright storage cabinets:

The refrigeration system on the cabinet consists of:

•An evaporator coil (PS = 60bar)

•A Danfoss AKVP 10-1 electronic expansion valve with coil and the cobber pipes used to connect the

system.

•3 temperature sensors Danfoss PT1000 marked according to Danfoss standard - room sensor (S3)

and super-heat sensors (S2) are AKS11, Evaporator/defrost sensor (S5) is AKS12.

•A Carel suction line pressure transmitter (0-5V radiometric type (0-45 bargauge) female connection =

¼” SAE) Only connected electrically –To be fitted on the suction line by the installer.

After assembly, the system is pressure tested with 1,43 x PS (in the factory).

Recommended installation of the pressure transmitter is horizontally in the suction line (Done by the installer)

All parts are assembled and fitted on the cabinet, so that the installer does not need to access the evaporator

compartment or the controller box, during installation.

Exception: it will be necessary to open the controller box:

•in order to connect the cabinet controller to an external surveillance system. (Done by the installer)

•if e.g. drain line heater needs to be disconnected, when connection to an external drain solution.