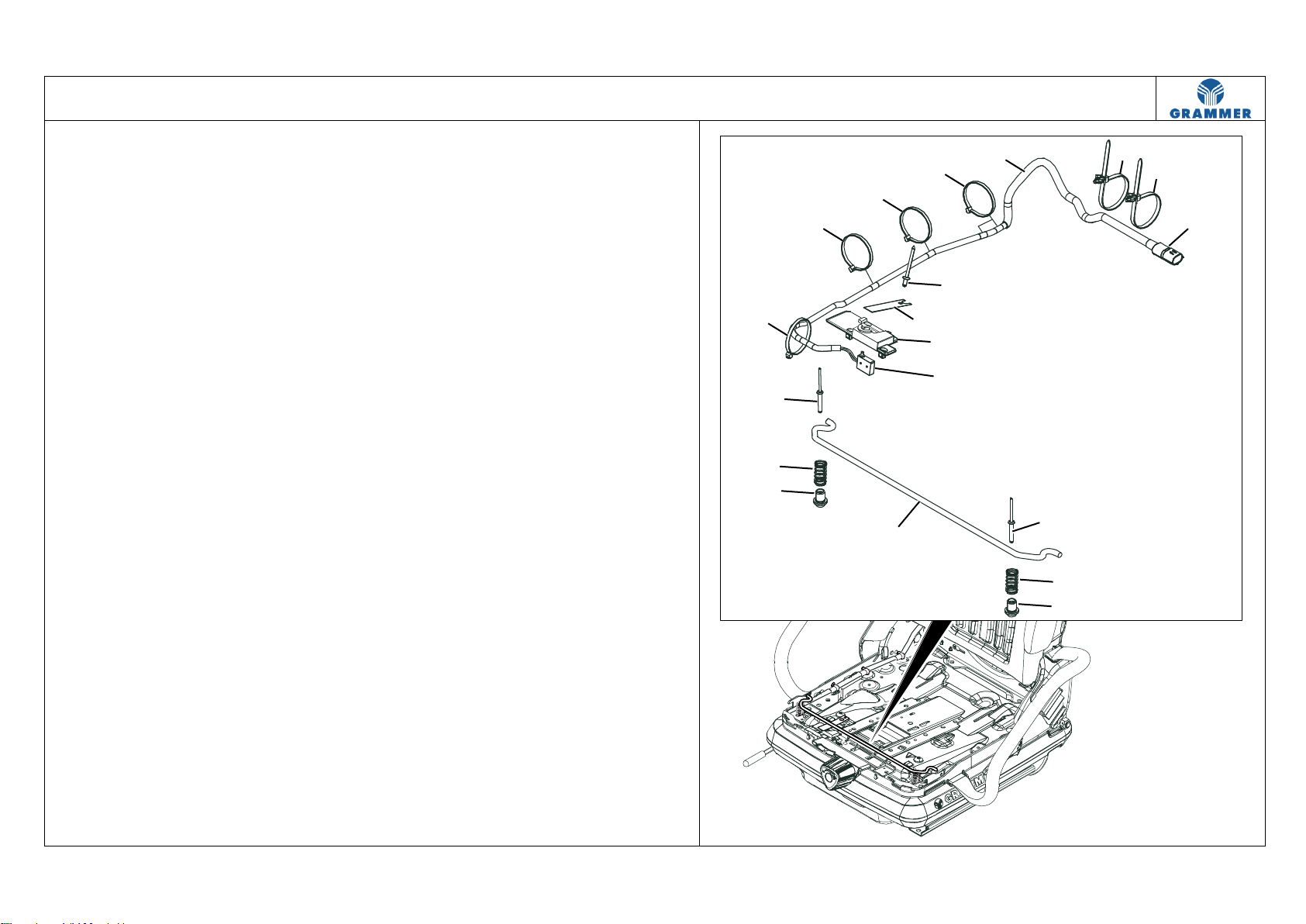

Bowden cables, cables, and hoses may only be secured by hand (therefore loose)

using cable ties in the specified locations. You must ensure that the Bowden cables,

cables and hoses are not pinched when adjusting the seat vertically and horizontally,

and that they follow the movement of the seat without causing tension.

All removed used parts must be replaced by the new parts supplied.

If no corresponding new part is included in the spare parts scope of delivery for

existing old parts, then they must be cleaned and inspected for further use.

The defective parts and wear parts must be replaced.

GRAMMER AG will reject any warranty claims if damaged or worn parts and

assemblies are not replaced by spare parts approved by GRAMMER.

Qualified personnel

The instructions represent the basis for proper and professional repair. The content of

the described work steps builds on the training status of a technician with a completed

vocational education and good knowledge of the product. This level of knowledge is

essential for performing the work described.

All information and instructions, especially the safety information in Chapter 1,

must be carefully read and followed completely, in order to prevent physical injury,

impairment of the operational safety of the seat, or damage to the seat as a result of

improper work.

It is ultimately impossible for GRAMMER AG to evaluate all situations which could

pose a risk of injury to the person involved. It is therefore absolutely necessary that

everyone performing repair work on the seat apply their expert knowledge to ensure

that their own safety is not jeopardised and that the seat is not negatively impacted

by the type of repair work selected, especially in regards to safety.

For these reasons, no liability can be assumed for such damage.

We also point out explicitly that all of the work steps described must only be carried

out in compliance with all directives and requirements of the responsible authorities

and of the health, accident and environmental protection regulations.

Right of modification and copyright

These seats are constantly being further developed. Please understand that we

must reserve the right to make changes to its form, equipment, and technology.

For these reasons, no claims can be derived from the content of this repair manual.

Reprinting, translation and reproduction, even as excerpts without our written

consent are prohibited.

GRAMMER AG PO box 14 54

D-92204 Amberg, Germany

Telephone +49 (0) 96 21 / 66-6822

www.grammer.com

Supplier and factory address:

GRAMMER AG

Köferinger Str. 9-13

D-92245 Kümmersbruck