Note: For those infrequent

situations where old and new

brackets are to be used on the

same worksurface, it is

recommended to increase the

height of the old style bracket by

using a 1⁄4" spacer (part number

46.5306). This spacer is

available upon request at no

charge from KI or the installer

may use their own spacer.

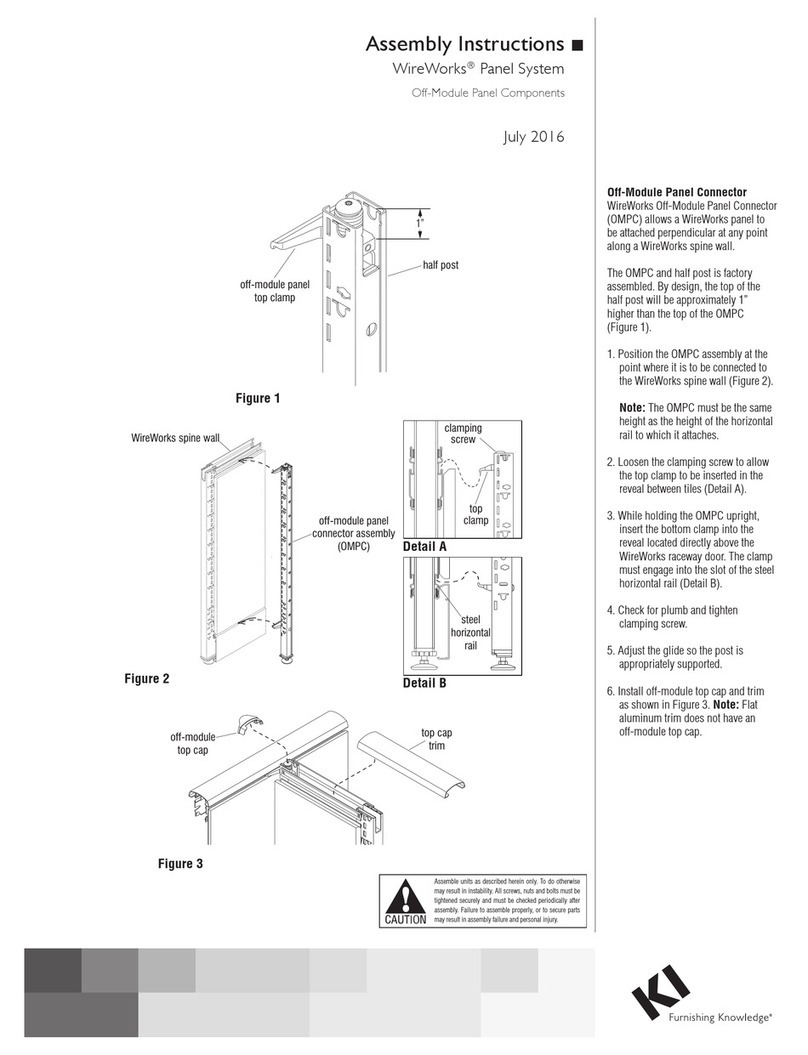

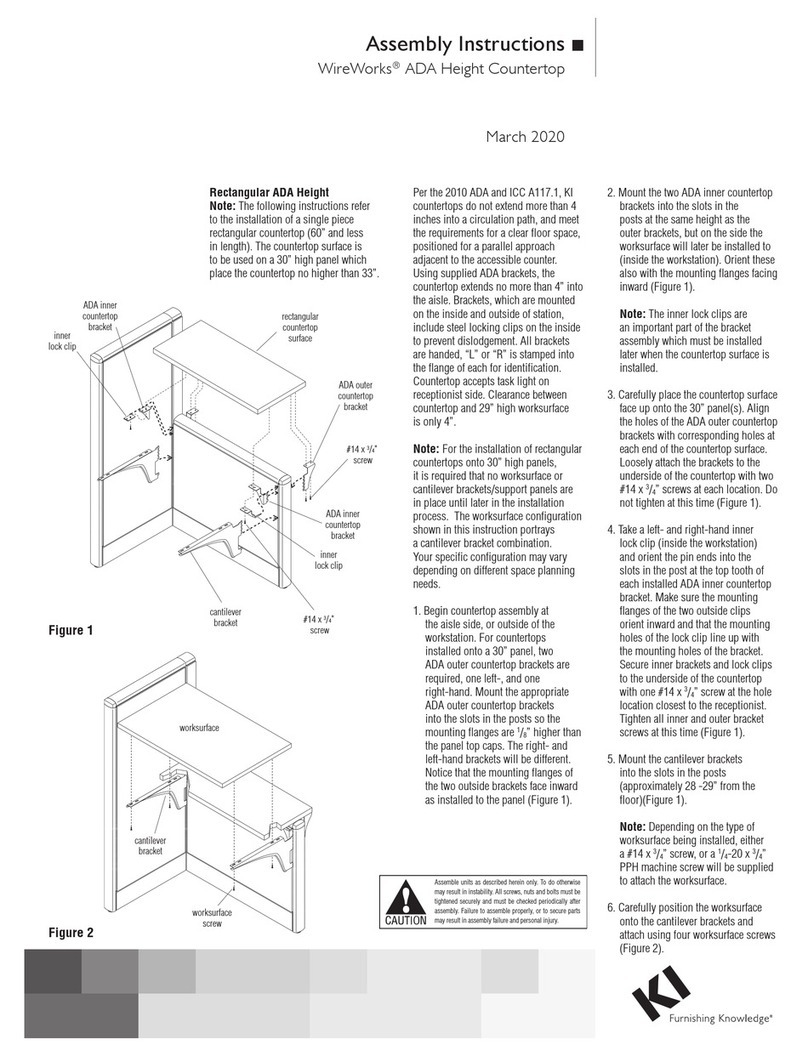

1. Determine at which height the

cantilever brackets are to be hung

on the panel (1" lower than the

desired worksurface height). The

panel trim rail groove is pre-

slotted for acceptance of bracket

teeth. Position the cantilever

brackets so the worksurface

flanges face inward. Hook the top

tooth of each bracket into the

trimrail first, and rotate the

brackets in. Press down to

engage the teeth and secure the

bracket.

Note: Worksurface support

brackets and lock clips are

provided to hold the worksurface

in place after installation.

Brackets and clips are right- or

left-handed (left shown).

2. Hook the worksurface support

bracket into the trimrail groove at

the side panel near the front edge

of the worksurface. Be sure the

bracket is hooked in at the same

height as the cantilever bracket.

3. Position the worksurface onto the

cantilever brackets so the holes

in the worksurface line up with

the slots in the brackets. Position

1⁄4" spacers (46.5306) on top of

the old style brackets, keeping

holes aligned. Insert #14 x 3⁄4"

screws. Fasten the cantilever

brackets to the underside of the

worksurface.

4. Be sure the worksurface support

bracket is securely hanging in the

trimrail. Position the support

bracket lock clip as shown and

orient the pin end into the trimrail

groove at the top tooth of the

installed worksurface support

bracket. Make sure that the hole

in the mounting flange of the lock

clip lines up with the hole in the

bracket. Secure the lock clip and

bracket to the underside of the

worksurface with one #14 x 3⁄4"

screw.

Assembly Instructions

WireWorks®Worksurface Reconfiguration

Utilizing Old and New Cantilever Brackets

December 2004

Assemble units as described herein only. To do otherwise

may result in instability. All screws, nuts and bolts must be

tightened securely and must be checked periodically after

assembly. Failure to assemble properly, or to secure parts

may result in assembly failure and injury.

1330 Bellevue Street • P. O. Box 8100 • Green Bay, WI 54308-8100 • Tel 1-800-424-2432 • www.ki.com

© 2004 KI All Rights Reserved • Litho in USA • Code KI-61643/TM/GT/1204

support bracket

lock clip

(left shown) new cantilever bracket

old worksurface

support bracket

(left shown)

1/4” spacers

old cantilever bracket

when using old brackets here,

install 1/4” spacers . . .

. . . to level worksurface

height when using

new brackets here.

work surface