G.R.A.S. Sound & Vibration

Pistonphone Types 42AA/42AA-S1 - Page 6

2. Theory

2.1 Principle

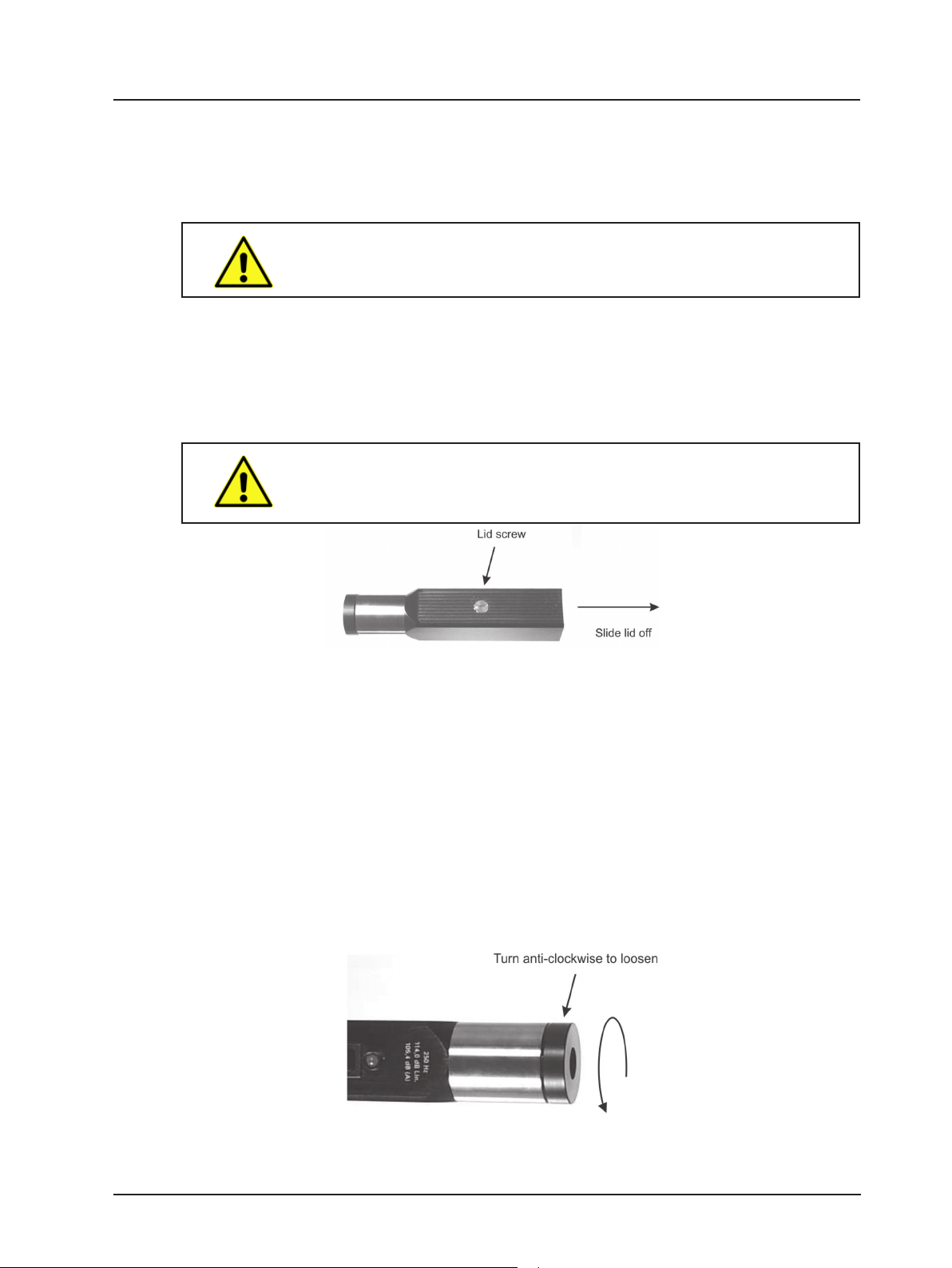

The Pistonphone works on the principle of a pair of similar opposing, reciprocating pistons

(Fig. 2.1) actuated by a precision-machined cam disc with a sinusoidal (SHM) prole. The cam

disc is mounted on the shaft of a small electric motor. The prole of the cam disc is such that the

pistons follow a sinusoidal movement at a frequency equal to four times the speed of rotation.

This results in a corresponding sinusodial variation in the effective volume of the closed coupler

and, consequently, an acoustic signal within it. The RMS pressure, P (in pascals), of this acous-

tic signal is given by:

Where :

γ is the ratio of specic heats for the gas in the coupler (for air this is 1.402 at 20 °C and

1 atm.)

P

0 is the ambient pressure in pascals (Pa)

A

p is the cross-sectional area of one piston in square metres (m

2)

S is the stroke length of the pistons in metres (m)

V is the coupler volume in cubic metres (m

3)

A

pand S are determined by the physical dimensions of the pistons and the cam disc; the ambi-

ent pressure refers, in most cases, to the barometric pressure of the atmosphere.

2.2 Volume Corrections

The volume of the coupler is dened partly by the dimensions of the coupler itself and partly the

effective load volume of the microphone. The effective load volume of the microphone is sum of

the equivalent volume and the front cavity volume. The front cavity volume of the microphone

is the volume between the microphone’s diaphragm and the protection grid plus the volume

contained in the slits of the protection grid.

The equivalent volume of the microphone is the apparent volume of the microphone behind the

diaphragm. Since the diaphragm is not perfectly stiff, it will be deected slightly by a sound pres-

sure. This slight deection of the diaphragm can be considered as equivalent to a small volume

and, as such, should be added to the sum of the grid and coupler volumes. Since the grid and

equivalent volumes can vary slightly from one type of microphone to another, the total volume of

the coupler will, accordingly, also vary slightly.

Fig. 2.1 Principle of the Pistonphone

P = γ⋅P 0⋅2 A p⋅S

V ⋅√ 2(1)