GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

We reserve the right to introduce modifications. No liability for printing errors. 02/2006

2

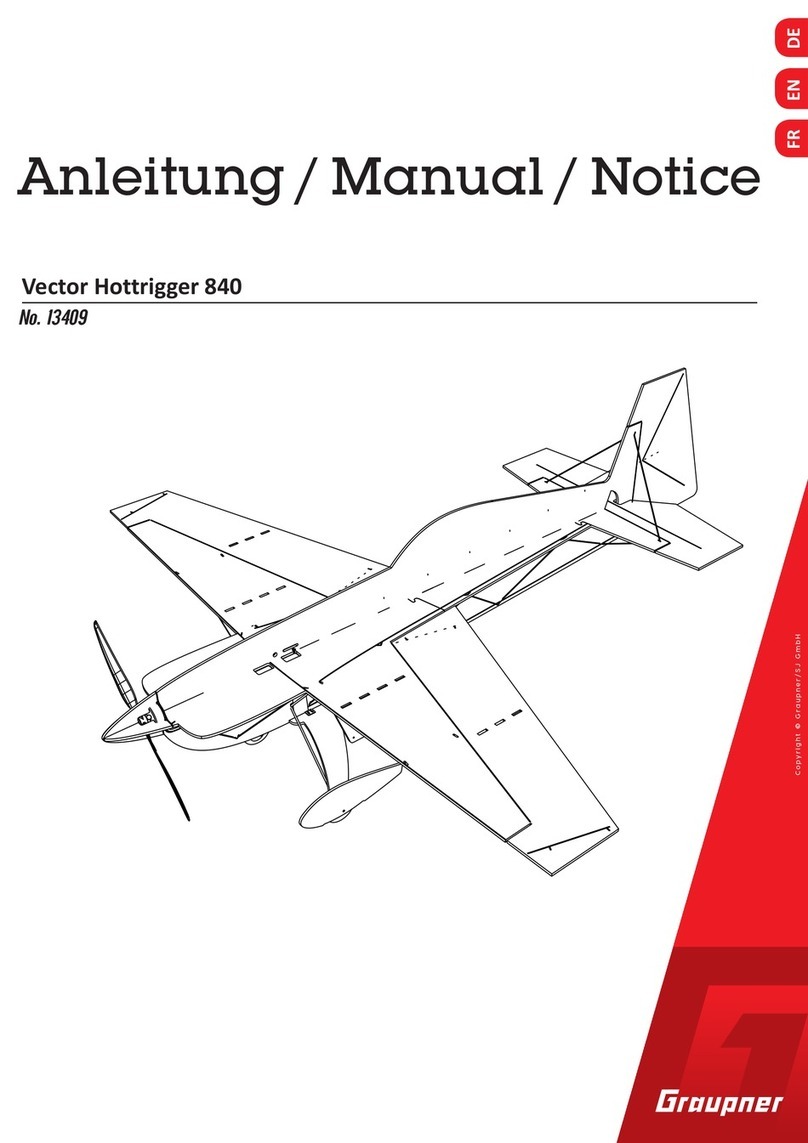

in multi-coloured iron-on film. Little work is required to complete the machine ready to fly;

this includes attaching the fin, screwing the tailplane to the fuselage, installing the motor

mount and motor, the undercarriage and the receiving system and linkages.

A four-function radio control system is sufficient to fly the model.

Caution: this model is not a toy!

If you are a beginner to this type of powered model, please ask an experienced model flyer

for help and support. If you attempt to operate the model without knowing what you are

doing, you could easily injure yourself or somebody else. Please keep your safety and

well-being in mind at all times.

Important Safety Notes

You have acquired a kit which can be assembled into a fully working RC model when fitted

out with suitable accessories. However, we as manufacturers have no control over the way

you build and operate your RC model aircraft, nor how you install, operate and maintain

the associated components, and for this reason we are obliged to deny all liability for loss,

damage or costs which are incurred due to the incorrect use of our products or due to

incompetent behaviour on the part of the user, or which are connected with such operation

in any way. Unless otherwise prescribed by binding law, the obligation of the GRAUPNER

company to pay compensation, regardless of the legal argument employed, is excluded.

This includes personal injury, death, damage to buildings, damages due to loss of

business or turnover, interruption of business or other direct or indirect consequent

damage whose root cause was the operation of the model.

The total liability in all cases and under all circumstances is limited to the amount of money

which you actually paid for the model.

This model is built and flown at the sole and express responsibility of the operator.

The only way to avoid injury to persons and damage to property is to handle and

operate the model with the greatest care and consideration at all times.

According to the new regulation of §103 Paragraph 3 of the LuftVZO (German Aviation

Approvals Office), all model aircraft - whether slow-flyer, park-flyer, glider, or model aircraft

propelled by any form of power plant - must be insured before the model is operated. If

you are not sure about this, please ask at your local model shop where the staff will be

glad to advise you.

These safety notes must be kept in a safe place. If you ever dispose of the model, be sure

to pass them on to the new owner.

Guarantee terms

The guarantee covers replacement of any parts which can be shown to exhibit

manufacturing faults or material defects within the guarantee period of 24 months from the

initial date of purchase. No other claims will be considered. Cost of transport, packing and

freight are payable by the purchaser. We accept no liability for damage in transit. When

you send the product to GRAUPNER, or to the approved Service Centre for your country,

you must include a clear and concise description of the fault together with the invoice

showing the date of purchase. The guarantee is invalid if the component or model fails due

to an accident, incompetent handling or incorrect usage.