GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors 12/2010

0062196

2

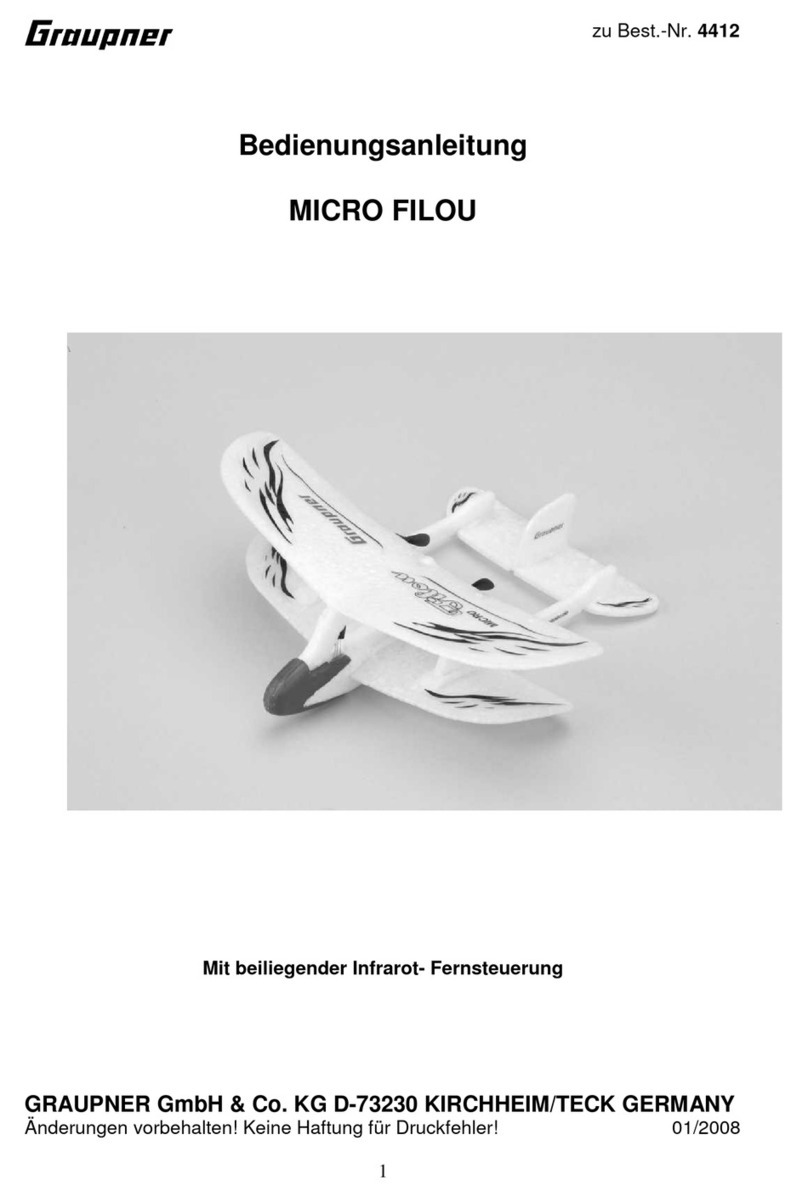

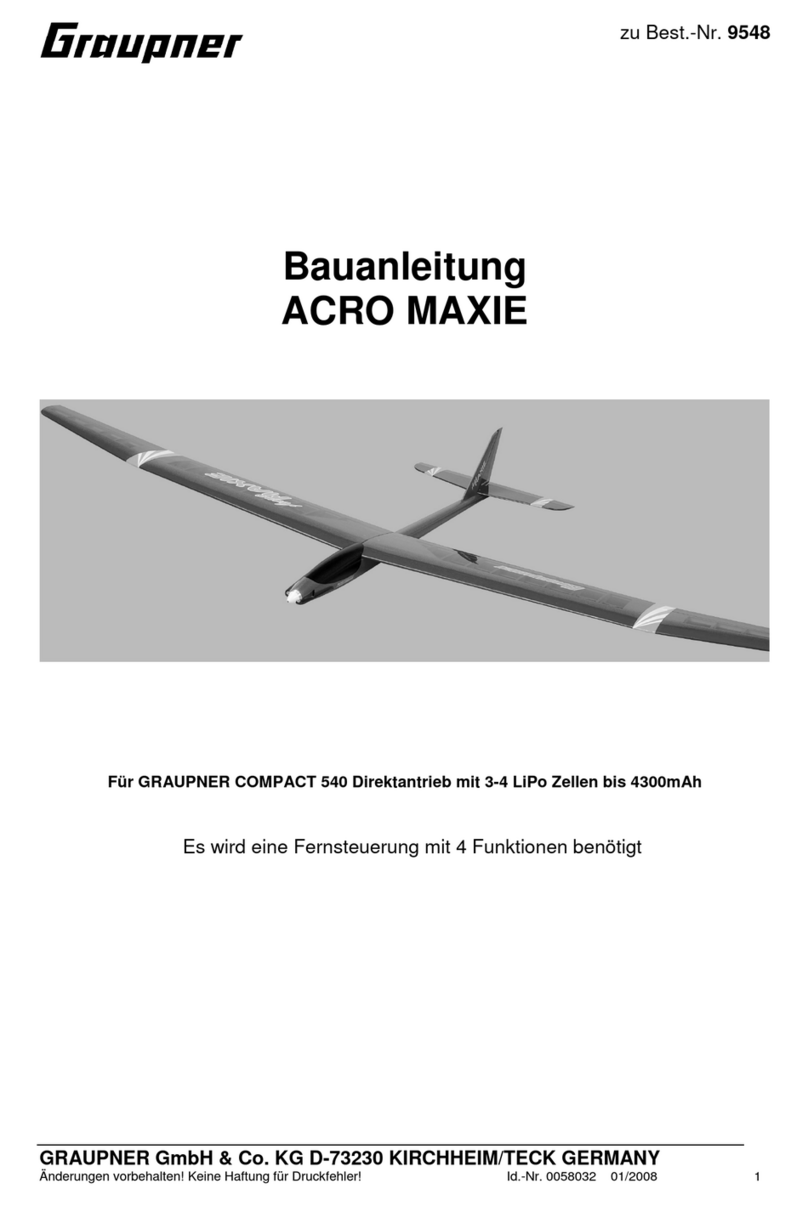

Specification

Wingspan approx. 3001 mm

Overall length approx. 1420 mm

Wing section TA-30 series, 8.3 %

Tailplane section 10%

Wing area approx. 48.2 dm²

Tailplane area approx. 4.2 dm²

Total surface area approx. 52.4 dm²

Min. all-up weight, according

to fittings, approx. 2450 g

Longitudinal dihedral approx. 1- 1.3°

Centre of Gravity approx. 84 - 88 mm aft of the wing root leading edge

Important safety notes

You have acquired a kit which can be assembled into a fully working RC model when

fitted out with suitable accessories. However, we as manufacturers have no control

over the way you build and fly your RC model aircraft, nor how you install, operate

and maintain the associated components, and for this reason we are obliged to deny

all liability for loss, damage or costs which are incurred due to the incompetent or

incorrect use and operation of our products, or which are connected with such

operation in any way. Unless otherwise prescribed by binding law, the obligation of

the GRAUPNER company to pay compensation, regardless of the legal argument

employed, is excluded. This includes personal injury, death, damage to buildings,

damage due to loss of business or turnover, interruption of business or other direct or

indirect consequent damage whose root cause was the operation of the model.

The total liability in all cases is limited to the amount of money which you actually

paid for this model.

This model aeroplane is built and flown at the sole and express responsibility of the

operator. The only way to avoid injury to persons and damage to property is to

handle and operate the model with the greatest care and consideration at all times.

During construction

When handling adhesives and solvent-based materials it is important to observe the

safety notes and instructions supplied by the manufacturer. Many glues and solvents

are capable of causing injury and damage to materials if they are not used com-

petently. Take waste glue and paint to your local model shop or toxic waste collection

centre.

Note that balsa knives, pins, etc. have sharp points and edges, and should be hand-

led carefully to avoid injury.

Take care to keep tools, adhesives and paints out of the reach of children.

A large, unobstructed working surface is a great advantage for all types of model-

making.

If you are a relative beginner and are not sure of any process, it is always best

to ask an experienced modeller for help.