3

DC Inverter Multi VRF System II

Service Manual

PRODUCT

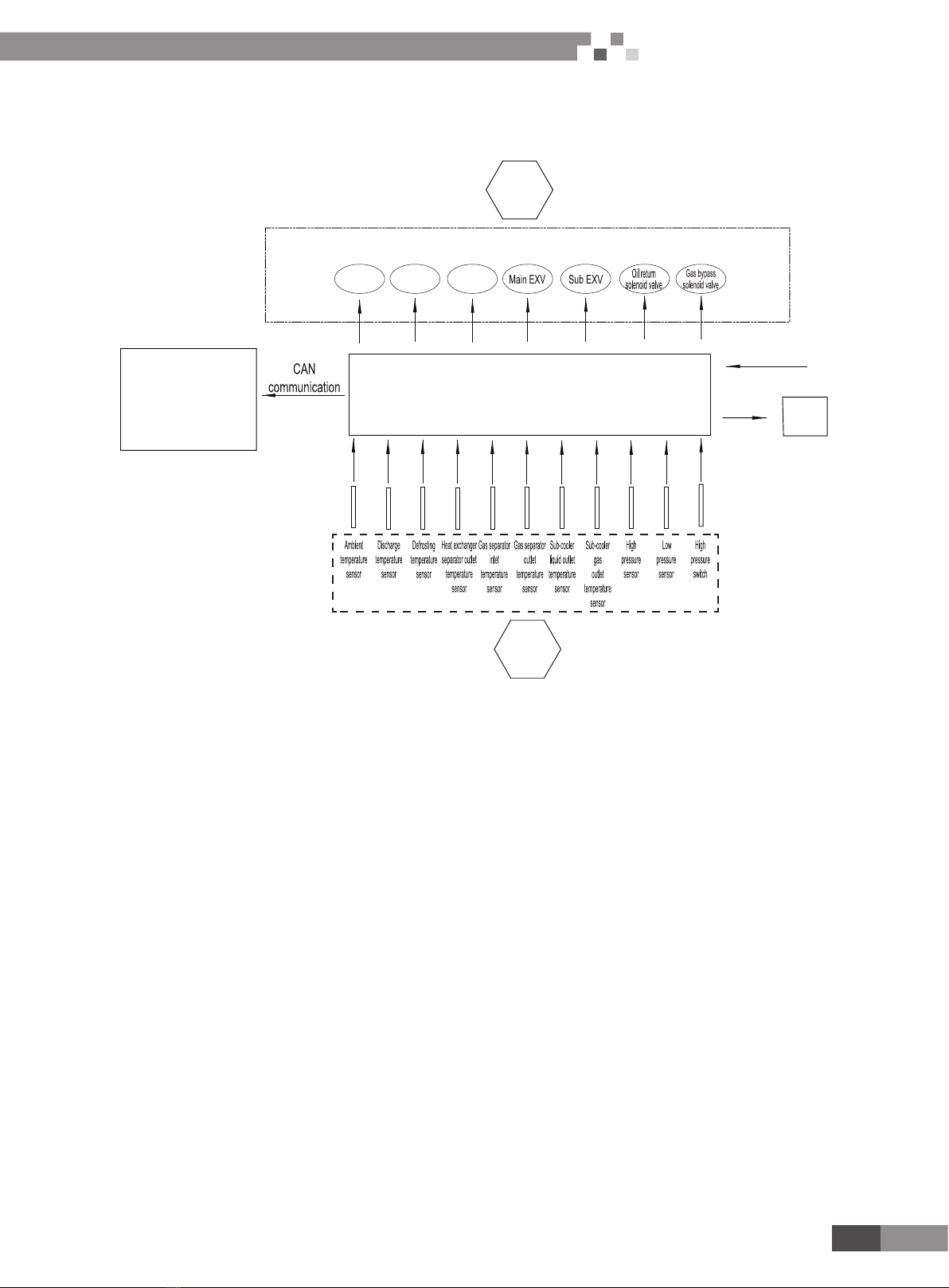

Due to the latest communication method—CAN Bus Communication, system’s anti-interference capability is stronger and the control

on indoor units is more accurate, with higher reliability. Specialized shield wire is no more needed and ordinary communication wire can be

applied in the construction, which has increased the installation exibility.

(3) Long connection pipe

The maximum length of connection pipe is 300m (in total) and the farthest connection pipe between indoor and outdoor units can be

120m’s long, which has extended the installation condition and reduced the limit of installation distance.

(4) Wide operation range

Units can operate reliably in a wide temperature range (cooling: -5~48oC, heating: -20~27oC).

(5) Fine sound quality

Through a series of optimized measures, system has reduced the throttle noise and oil return noise of indoor units, gas bypass noise,

etc. so that units are more comfortable regarding sound quality.

(6) Intelligent PID capacity regulation

With the independently developed PID capacity regulation technology, units are able to control the indoor ambient temperature more

quickly and reduce the uctuation of room temperature.

(7) Complete protection

Units are equipped with a series of protection to accurately identify errors and protect the units, which has ensured reliable and safe

operation.

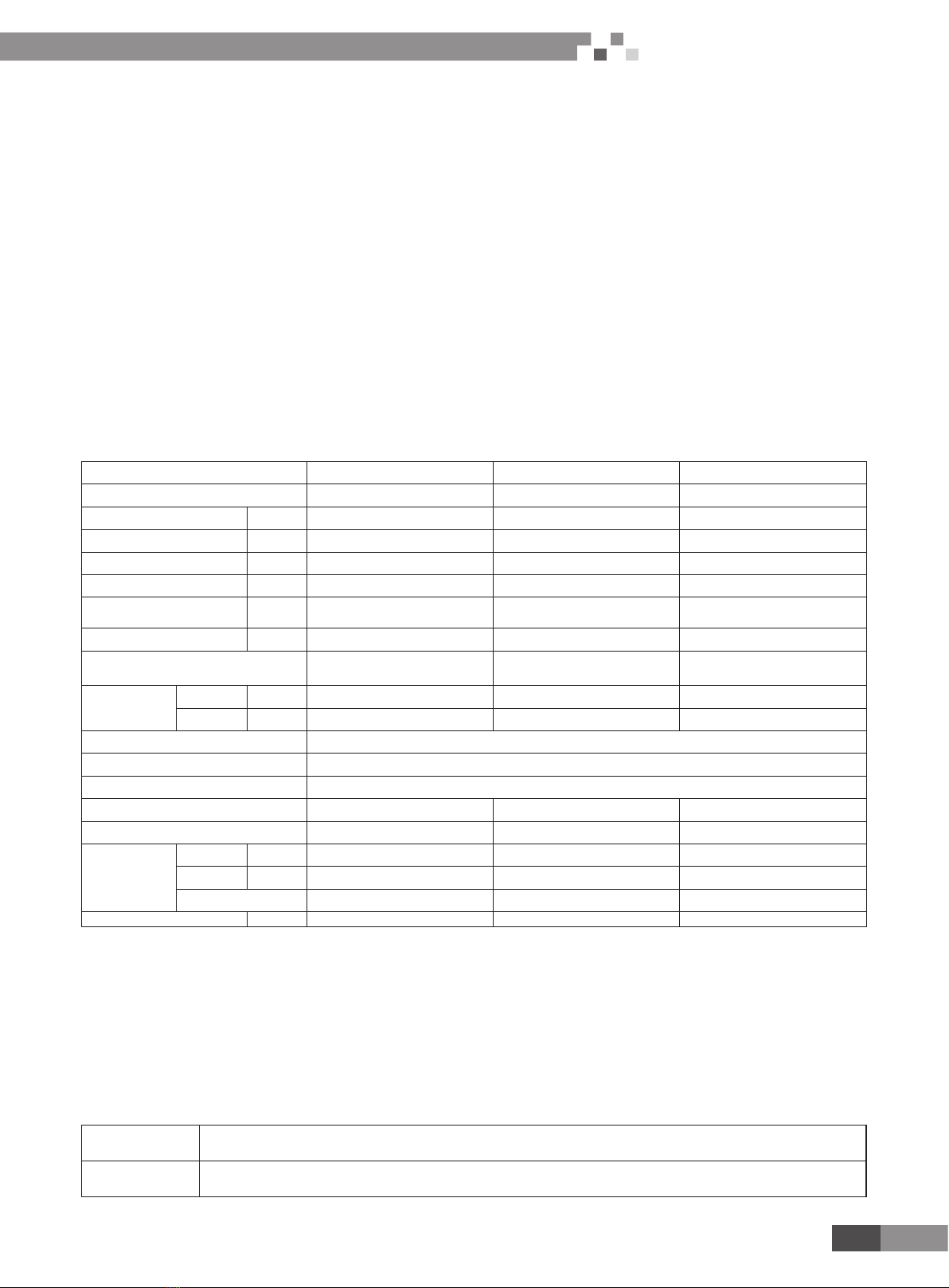

4 SPECIFICATIONS

4.1 Specications

Model GMV-120WL/A-T GMV-140WL/A-T GMV-160WL/A-T

Product code CN850W0180 CN850W0170 CN850W0160

Cooling capacity kW 12.1 14 16

Heating capacity kW 14 16.5 18.5

Circulating air volume m3/h 6000 6300 6600

Noise dB(A) 55 56 58

Refrigerant charge

volume kg 5 5 5

Energy efciency level Level 1 1 1

Power supply 220-240V~50Hz

208-230V~60Hz

220-240V~50Hz

208-230V~60Hz

220-240V~50Hz

208-230V~60Hz

Rated power

input

Cooling kW 3.05 3.98 4.85

Heating kW 3.27 3.99 4.67

Unit Dimensions (mm)(WxDxH) 900×340×1345

Package Dimensions (mm)(WxDxH) 998×458×1515

Compressor QXAS-F428zX050A

Water-proof level IPX4 IPX4 IPX4

Suitable climite T1 T1 T1

Connection

pipe

Gas mm Ф15.9 Ф15.9 Ф19.05

Liquid mm Ф9.52 Ф9.52 Ф9.52

Connection Method Bell mouth connection Bell mouth connection Bell mouth connection

Net weight kg 110 110 110

Note:

① . Units conform to design standard: GB/T 18837-2002.

② . Specications may be changed due to product improvement. Please refer to nameplates of the units.

③ . Noise data are collected from a semi-anechoic room. Decibels may be slightly higher in actual operation due to environmental

change.

④ . Refrigerant charge volume listed in the table is based on the condition where indoor and outdoor units are at a same level and with

no connection pipe. Supplementary refrigerant needs to be charged according to actual circumstance.

⑤ . The sectional area of conducting wire is only applicable when the length is within 15m. If it’s over 15m’s long, sectional area must

be increased accordingly, otherwise, over-current may burn the wires.

4.2 Operation range

Cooling Outdoor temperature: -5~48oC

Heating Outdoor temperature: -20~27oC