3

3.3 Inspection before Commissioning.......................................................................................... 197

4.COMMISSIONING OPERATION........................................................................................................... 202

4.1 Commissioning Operation of Hydro Box................................................................................ 202

4.2 Commissioning Operation of the Entire Unit ......................................................................... 205

5. DIP SWITH INSTRUCTIONS OF GMV5 UNIC ..................................................................................... 219

5.1 GMV5 Unic Outdoor Unit (GMV-S224W/A-X,GMV-S280W/A-X).......................................... 219

5.2 Hydro Box (NRQD16G/A-S) .................................................................................................. 241

CHAPTER 5 MAINTENANCE............................................................................................................. 257

1. TABLE OF ERROR CODES................................................................................................................ 257

2. SETTING OF OUTDOOR UNIT NOISE REDUCTION ................................................................................ 261

2.1 Setting instruction .................................................................................................................. 261

2.2 Effect of quiret mode:............................................................................................................. 262

3. INSTRUCTION FOR ―LEAVING OUT CHARGING WATER‖BETWEEN GENERATORAND WATER TANK ............ 263

3.1 Description of question .......................................................................................................... 263

3.2 Analysis.................................................................................................................................. 263

3.3 Troubleshooting ..................................................................................................................... 263

4. TROUBLESHOOTING........................................................................................................................ 265

4.1 Analysis in Forms................................................................................................................... 265

4.2Flowchart analysis .................................................................................................................. 287

5.POWER DISTRIBUTION..................................................................................................................... 309

5.1 Power distribution method ..................................................................................................... 309

5.2 Introduction on key electric parts........................................................................................... 309

5.3 Circuit Diagram ...................................................................................................................... 310

6.ASSEMBLY AND DISASSEMBLY OF PARTS ...........................................................................................311

6.1 Introduction on key parts ........................................................................................................311

6.2 Assembly and disassembly of key parts................................................................................ 314

7. COMMON MAINTENANCE................................................................................................................. 327

7.1 Outdoor Unit Heat Exchanger................................................................................................ 327

7.2 Drain Pipe .............................................................................................................................. 327

7.3 Notice at the beginning of use season................................................................................... 327

7.4 Maintenance at the end of use season.................................................................................. 327

7.5 Parts Replacement ................................................................................................................ 327

7.6 System Leak Detection.......................................................................................................... 327

7.7 System Vacuum Pumping...................................................................................................... 327

8.EXPLODED VIEWS AND LIST OF SPARE PARTS................................................................................... 329

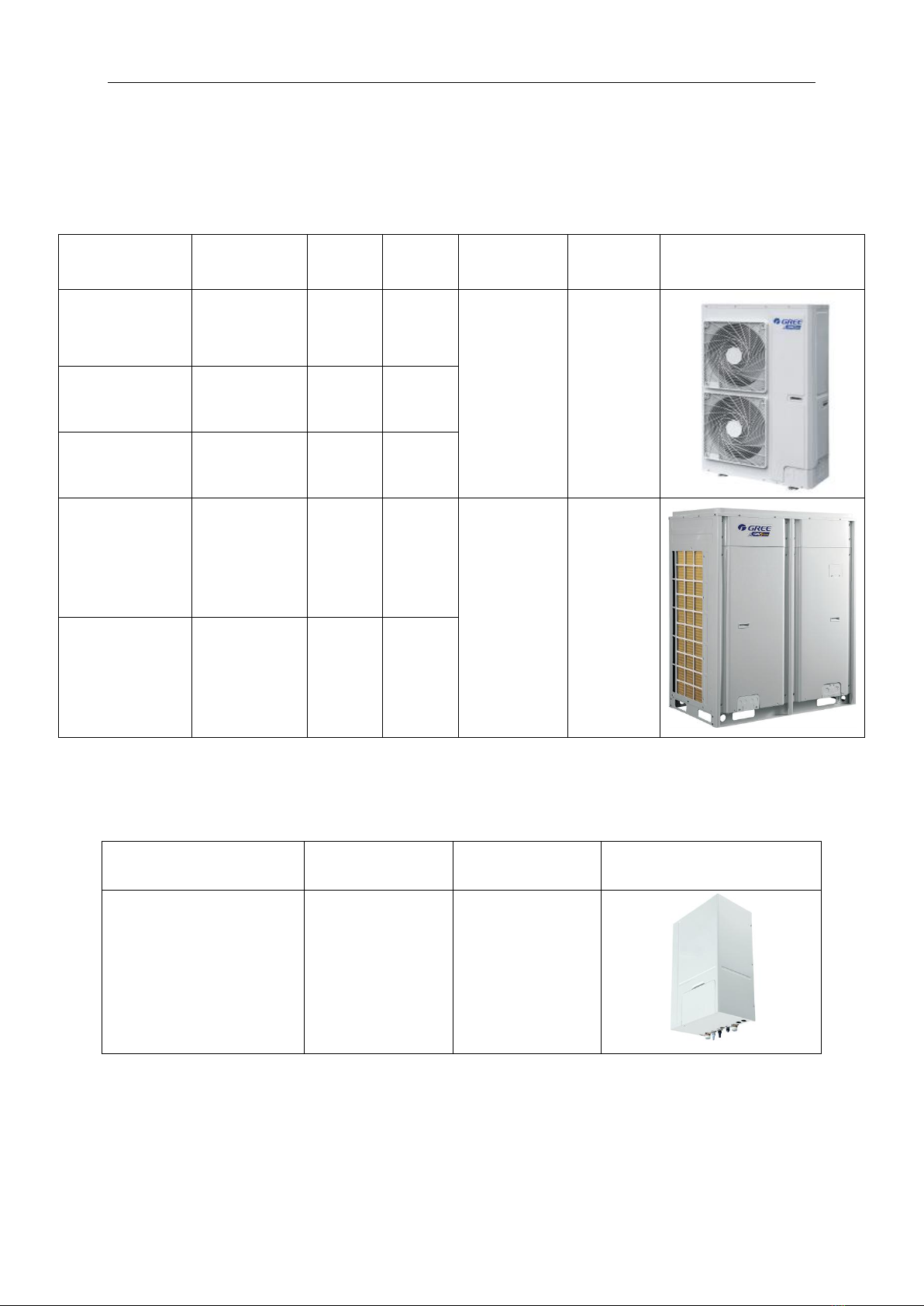

8.1 Outdoor Unit........................................................................................................................... 329

8.2 Hydro Box .............................................................................................................................. 332

CHAPTER 6 CARE............................................................................................................................. 335

1.CARE ............................................................................................................................................. 335

1.1 Outdoor Unit Heat Exchanger................................................................................................ 335

1.2 Drain Pipe .............................................................................................................................. 335

1.3 Notices at the Beginning of Use Season ............................................................................... 335

1.4 Notices at the End of Use Season......................................................................................... 335

1.5 Parts Replacement ................................................................................................................ 335

CHAPTER 7 MONITORING SOFTWARE .......................................................................................... 336

1FUNCTION INTRODUCTION................................................................................................................ 336

2CONNECTION OF COMPUTER AND UNITS........................................................................................... 336

3HARDWARE INTRODUCTION.............................................................................................................. 337

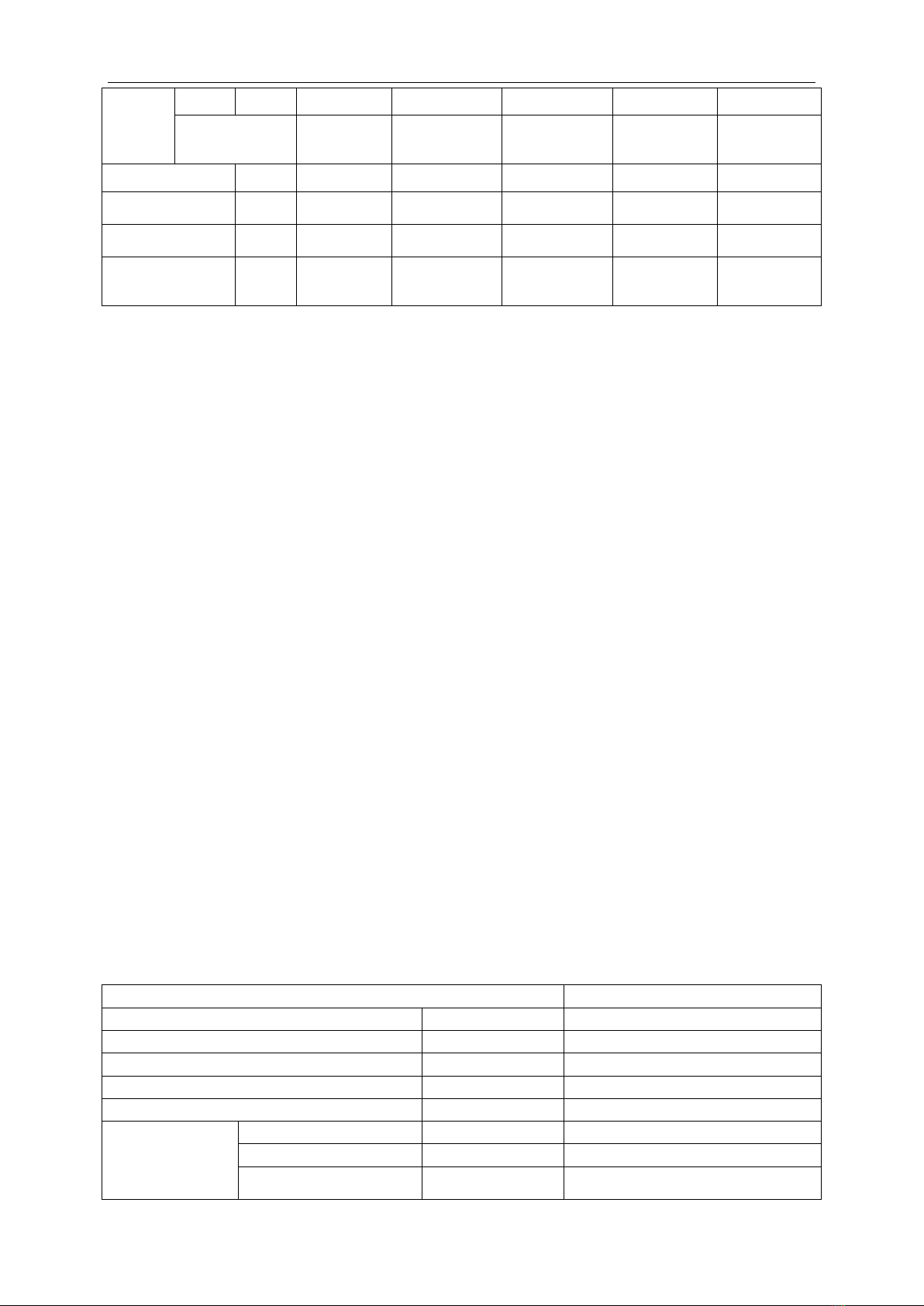

3.1 List of parts ............................................................................................................................ 337

3.2 Gree USB Data Converter..................................................................................................... 337

3.3 Communication Board ........................................................................................................... 339

3.4 Communication Wire.............................................................................................................. 339

4SOFTWARE INTRODUCTION.............................................................................................................. 340

4.1 Installation Requirements ...................................................................................................... 340

4.2 Installation Flowchart............................................................................................................. 342

4.3 Installation Procedure............................................................................................................ 342

5. USE OF SOFTWARE ........................................................................................................................ 359

5.1 Introduction of Functions ....................................................................................................... 359

5.2 Operation Methods ................................................................................................................ 359

6. DEBUGGING OF SOFTWARE............................................................................................................. 383