Contents

Foreword ....................................................................... 2

User Notes ..................................................................... 2

List of Drawings ................................................................. 3

Pride of the Pacific Component List ................................................. 4

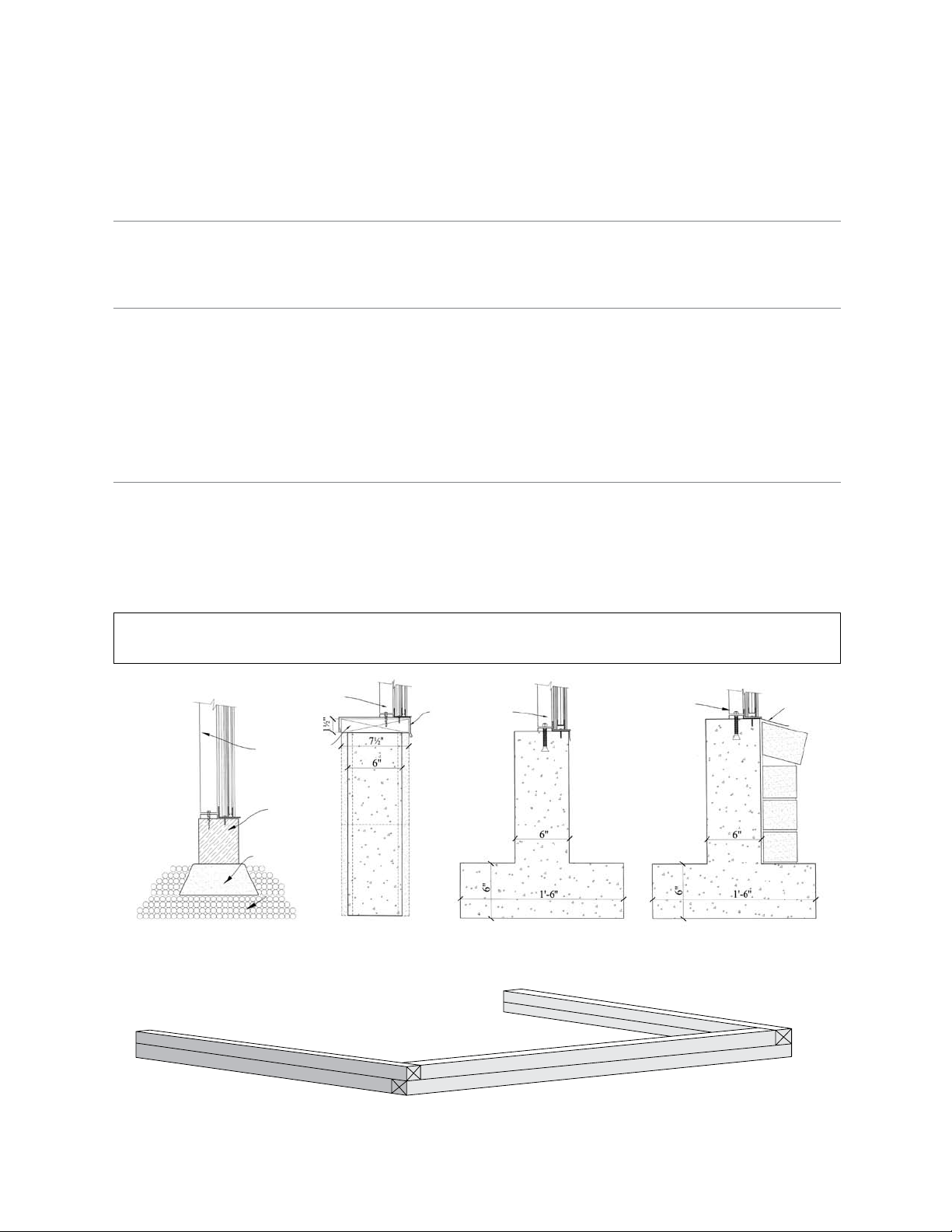

Foundations .................................................................... 5

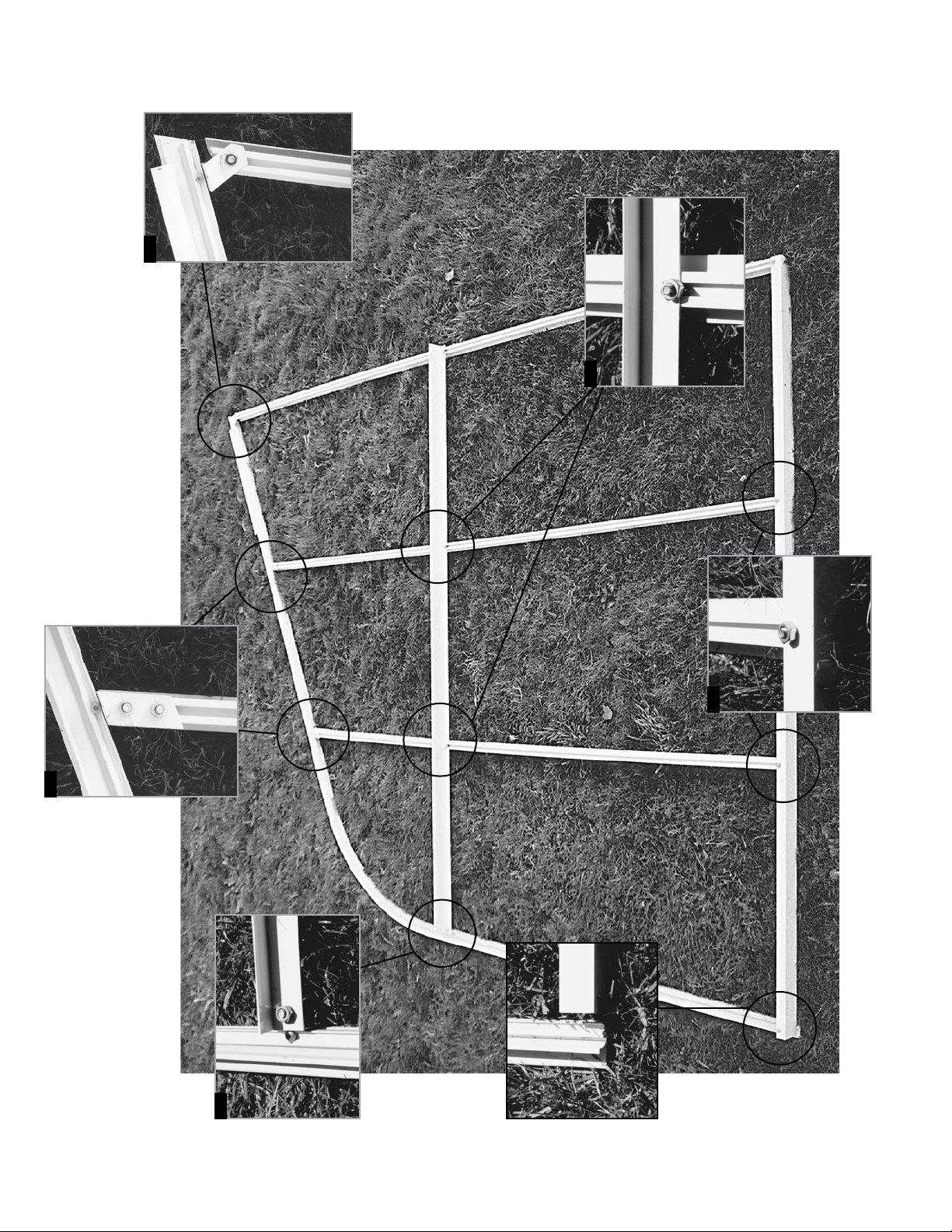

Assembly Of The Aluminum Frame

A. Back Gable End Assembly ................................................... 7

B. Front Gable End Assembly With Door ..........................................9

C. Taping Glass Bars With Foam ............................................... 12

Aluminum Frame Installation

1. Side Base/Sill............................................................. 13

2. Front Gable End .......................................................... 13

3. Back Gable End........................................................... 13

4. Ridge ................................................................... 13

4A. Truss Assembly Installation (if necessary) ...........................See Appendix A

5. Glass bars With Sliders (#1 or #2)............................................ 13

6. Ventframe Angle .......................................................... 14

7. Glass bars ............................................................... 14

8. Gutter................................................................... 14

9. Roof Purlin (Channel) ..................................................... 14

10. Center Bars .............................................................. 14

11. Tape All Glass bars ........................................................ 14

11A. Side Vents, Intake Shutter and Exhaust Fan Installation (if necessary)...See Appendix B - E

Glass And Cap Installation

General Information....................................................... 22

12. Glazing ................................................................. 22

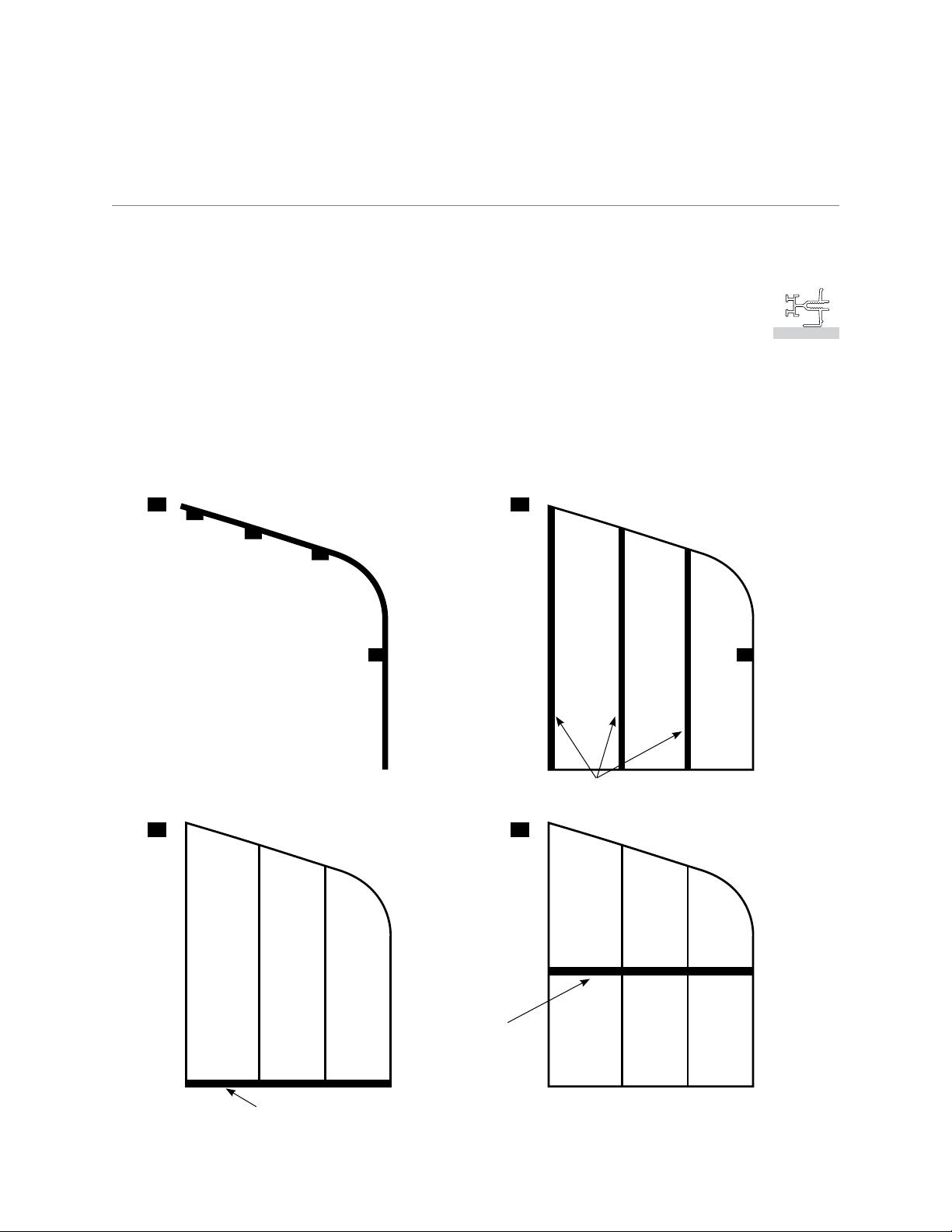

13A-E. Side Walls ............................................................22 - 26

14. Ends .................................................................... 26

15. Sealing The Greenhouse.................................................... 26

Door And Vent Installation

16. Door Installation ......................................................... 27

17. Vent Assembly ........................................................... 29

18. Vent Installation .......................................................... 29

Appendices: Optional Installations

Truss Installation .................................................. Appendix A

Vent Opener ...................................................... Appendix B

Exhaust Fan ....................................................... Appendix C

Side Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Appendix D

Glass Louvre ...................................................... Appendix E

Perlin Installation ...................................................Appendix F

Greenhouse Bench .................................................Appendix G

Roof Vent Screen...................................................Appendix H

Side Vent Screen ....................................................Appendix I

Wire Shelving ......................................................Appendix J

Miscellaneous Assembly Details: 1–3

– 1 –