Foreword

Your Traditional greenhouse is designed and constructed to the highest engineering standards and

provides structural strength and maintenance-free service for year-round gardening pleasure.

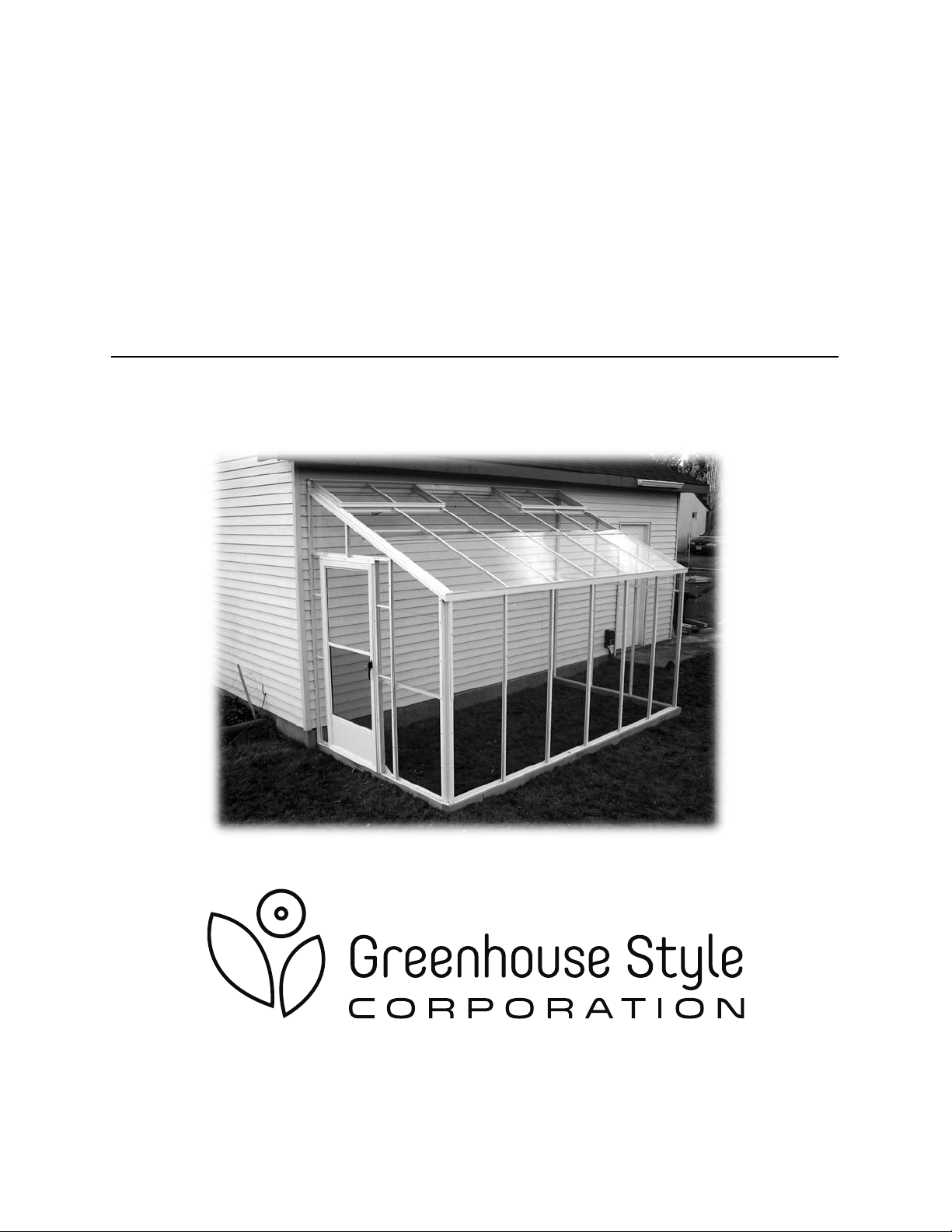

The Traditional greenhouse must be built upon a firm, level surface. The greenhouse foundation or

sill can be made from pre-treated timbers, concrete or bricks. Whatever your choice of material, the

base must be square and level.

When selecting a site for your greenhouse, keep in mind that a flat, level site is essential so that

the greenhouse can be easily installed and the complete structure is stable and secure. If possible,

choose a site with proper water drainage.

Locating the greenhouse in a north-south position is most suitable for raising summer and autumn

crops since the sun’s rays will be on the greenhouse from daybreak until sunset. An east-west

position is ideal for early spring and winter crops since the winter months, with shorter daylight

hours, still allow six hours of light exposure to the greenhouse.

Try to locate your greenhouse for easy access, especially to the necessary power and water that is

required for greenhouse gardening.

Please watch the enclosed video and follow the steps in this manual for your greenhouse

installation. Remember, if all else fails, read the instructions.

User Notes

The Traditional greenhouse structure has been designed to

withstand extreme weather conditions such as high winds and

accumulated snowfall. Hanging baskets and sidewall shelving can

also be attached to its sturdy frame. The greenhouse design also

makes it possible to add extra sections at a later date.

Once a year the greenhouse needs to be completely washed inside

and out. You should do this task when your greenhouse contains

the least number of plants, generally just before the garden plants

are brought in for wintering over. A recommended cleaning

solution is a mixture of hot water with a disinfectant such as Lysol

or Pinesol. Any benches, shelving, plastic trays, pots and baskets

should also be cleaned thoroughly. Prevention is the best known

method for controlling pests and diseases in the greenhouse.

– 2 –

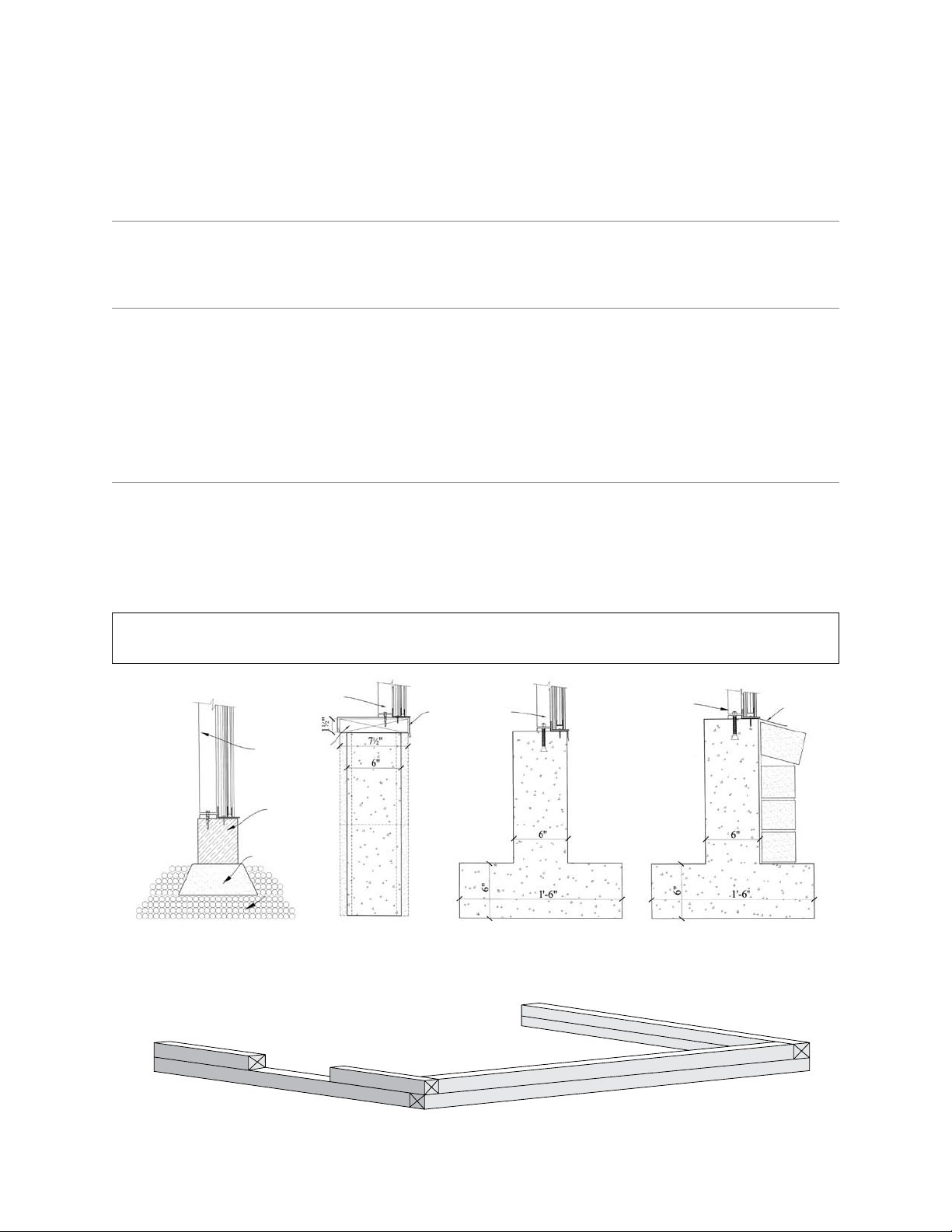

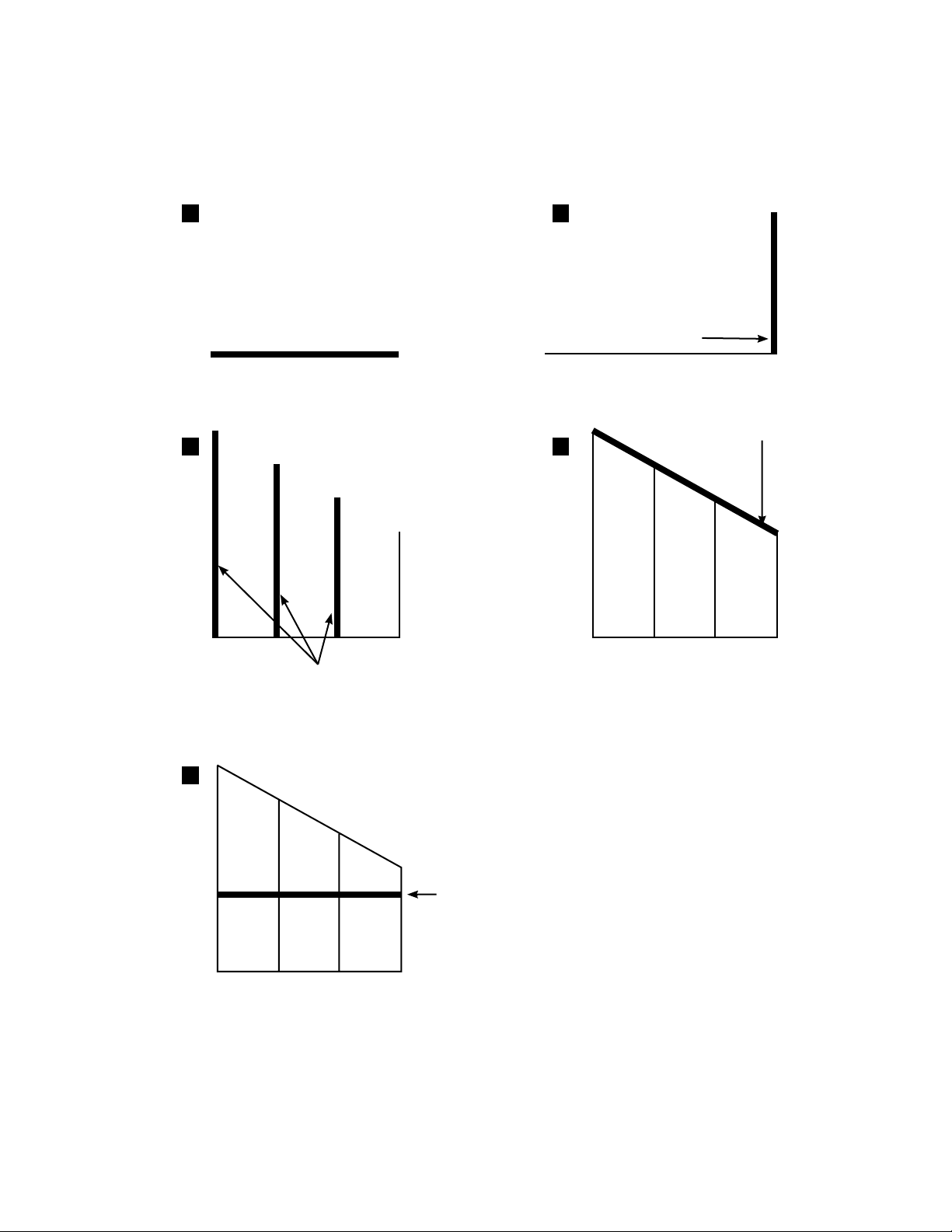

PLEASE NOTE: The

Illustrations found

in this manual may

not be specific to your

greenhouse, however

the detail of aluminum

shapes are all consistent.

The user notes are a

generic instruction for

all Traditional Series

Greenhouses – assembly

instructions are

common, only the sizes

number of pieces and

sizes vary.