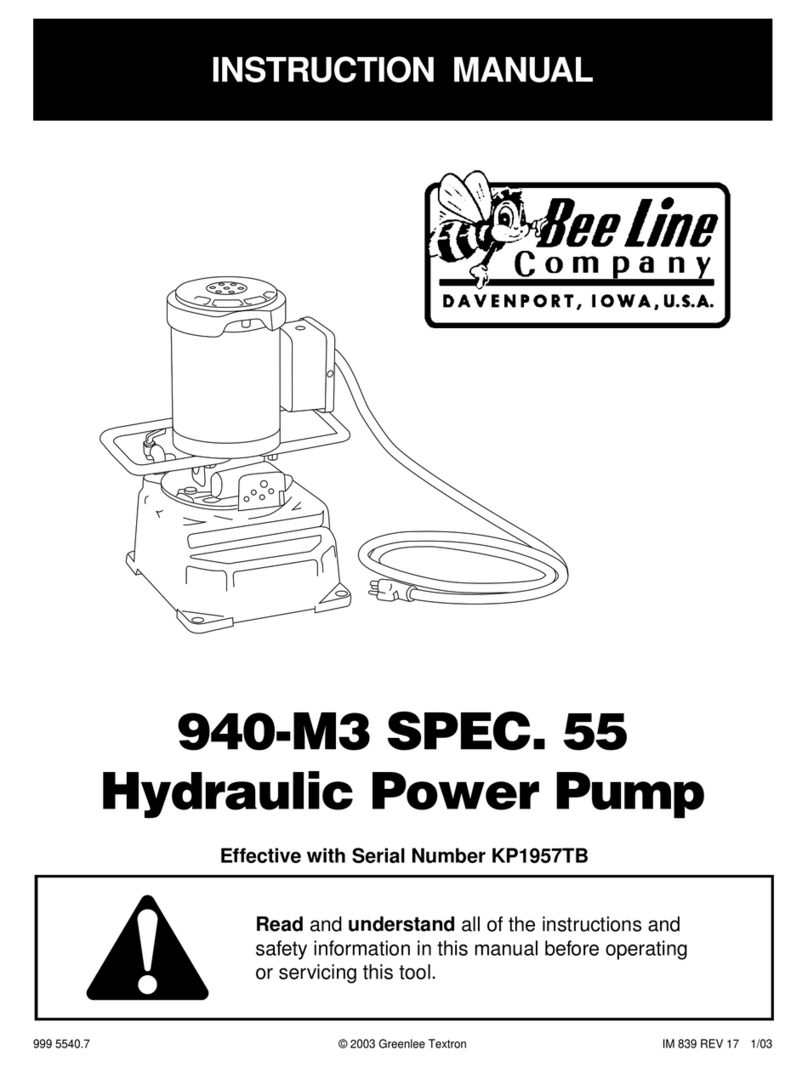

Greenlee Textron / Subsidiary of Textron Inc. 54455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

940-PS Series Hydraulic Power Pumps

Pump Specifications

Check to see that vent unit is not clogged before

attempting to operate pump.

Never use synthetic fluids or fluids with poor

lubricating qualities, i.e., brake fluids, etc., as

permanent injury to the pump will result.

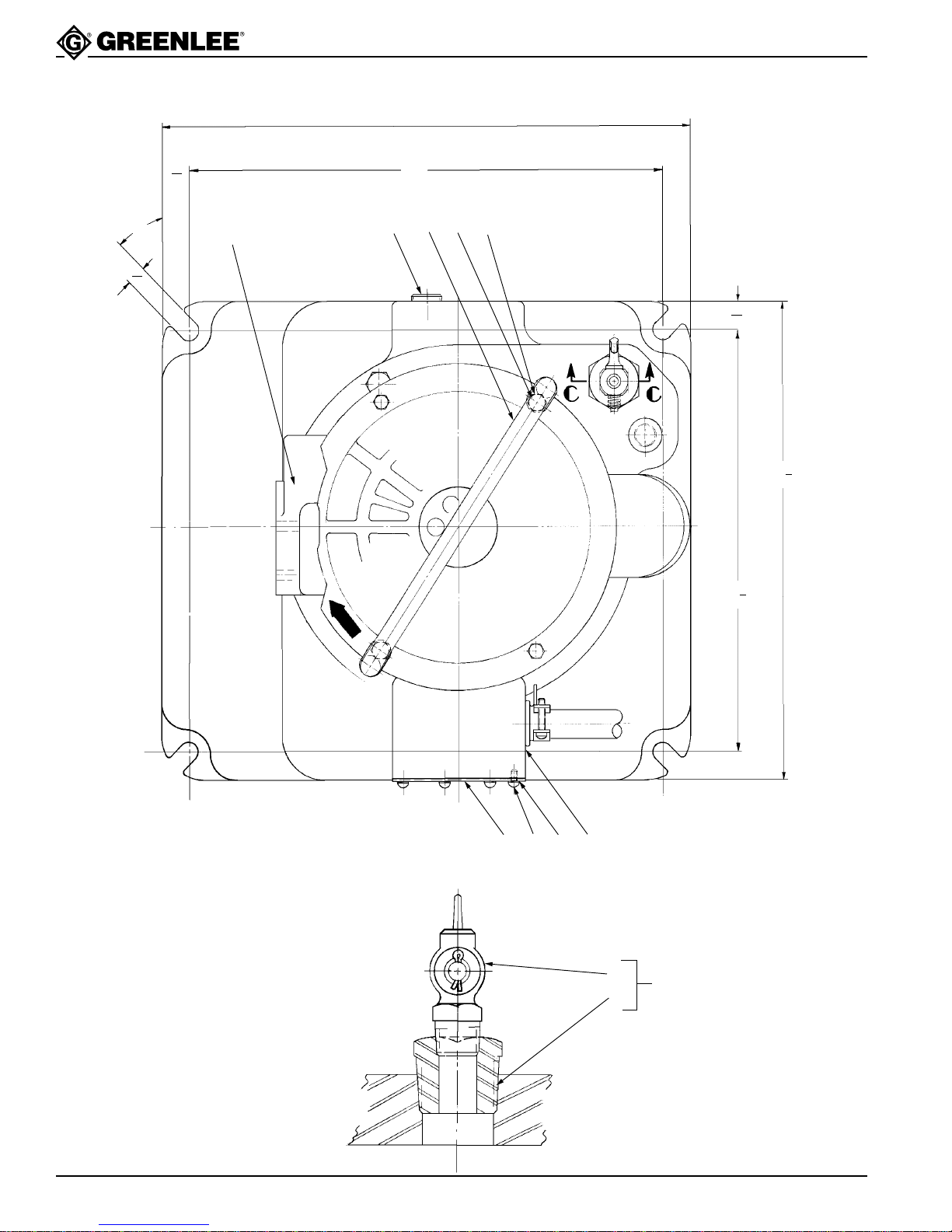

Draining Oil Reservoir. Unscrew and remove 3/8 inch

pipe plug (60) from side of pump base. Turn pump on its

side to drain all oil from reservoir. Be sure to replace

plug before refilling reservoir with oil.

Eight quarts are required of which 6-1/4 quarts are

usable. A minimum of 1-3/4 quarts must be at the

bottom of the reservoir at all times during operation.

Be sure that your complete operation does not require

more than the usable amount of oil.

To refill or add oil to the reservoir, proceed as follows:

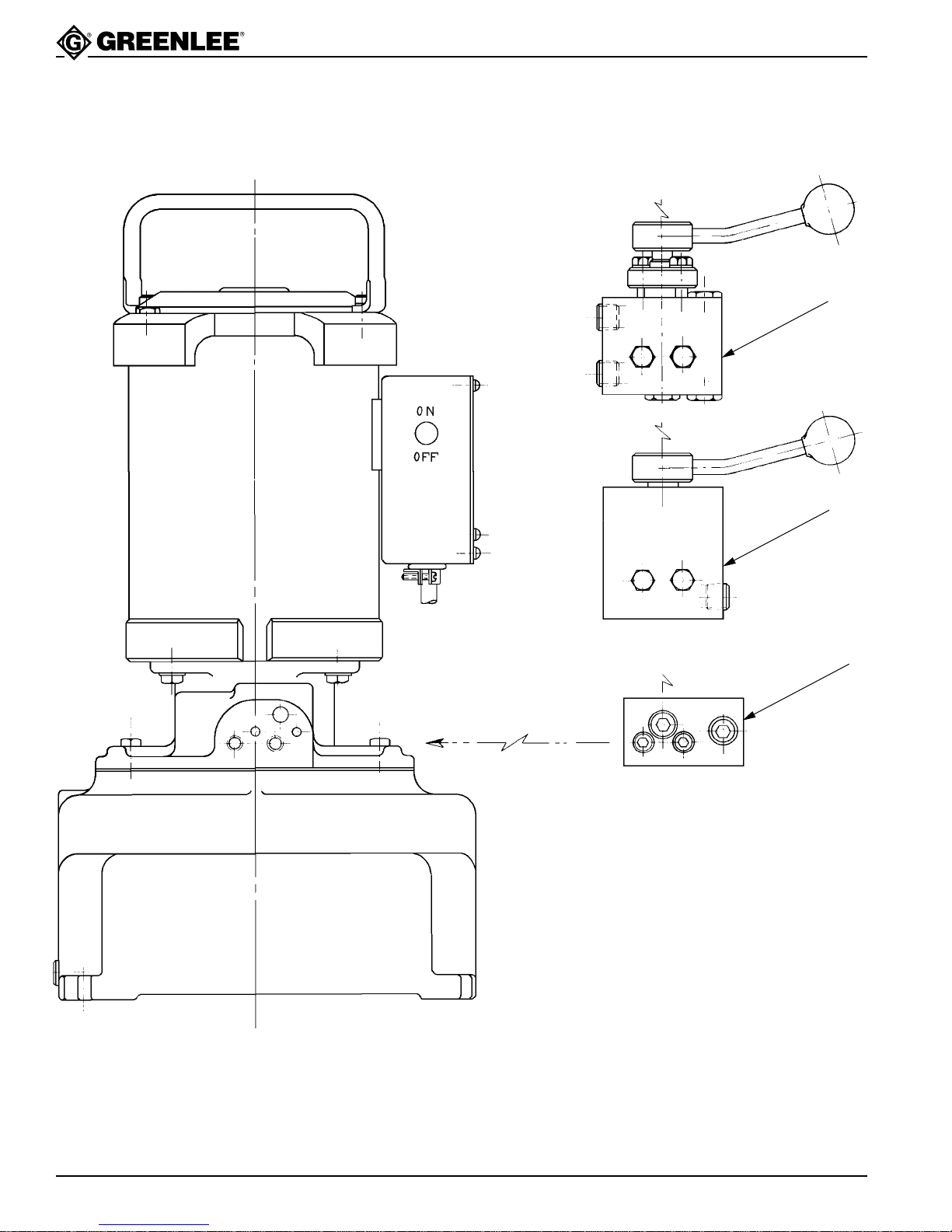

1. Remove vent unit from top of reservoir (B).

2. Add oil to within 1/2" of top of reservoir when ram is

retracted.

3. Install vent unit (B) securely in place.

Servicing Instructions

Filling Oil Reservoir. The oil reservoir must be kept

filled with a good grade of light hydraulic oil—Greenlee

905 0806.8 hydraulic oil or equal in order or the pump to

operate properly.

Flushing System. As long as these pumps are used as

outlined in the operating instructions, long, trouble-free

performance can be expected. To maintain this perform-

ance, it is absolutely essential that dirt or other foreign

matter be kept out of the system as this is the most

common cause of hydraulic system failure. Therefore,

when opening up the pump for any reason, such as

making pipe connections, adjusting pressure or any

repair, be sure to exercise extreme care in cleanliness

and to use clean tools and cloths. If, at any time, dirt is

suspected to have found its way into the system, the

entire oil system should be flushed as follows:

1. Drain oil from reservoir.

2. Fill reservoir with any recommended flushing oil or

clean kerosene and operate pump. Work the control

handle back and forth several times during flushing

to wash all foreign particles from the control valve

unit.

Note: Do not operate pump for a very long time as

system is not designed to operate with flushing

oil or kerosene.

3. Drain flushing oil or kerosene from reservoir and

refill with new oil.

Motor Maintenance

The 1 hp or 1-1/2 hp motors used on these power

pumps, when in need of repairs, should be repaired by

the manufacturer of the motor or at one of the qualified

GE Service Stations.

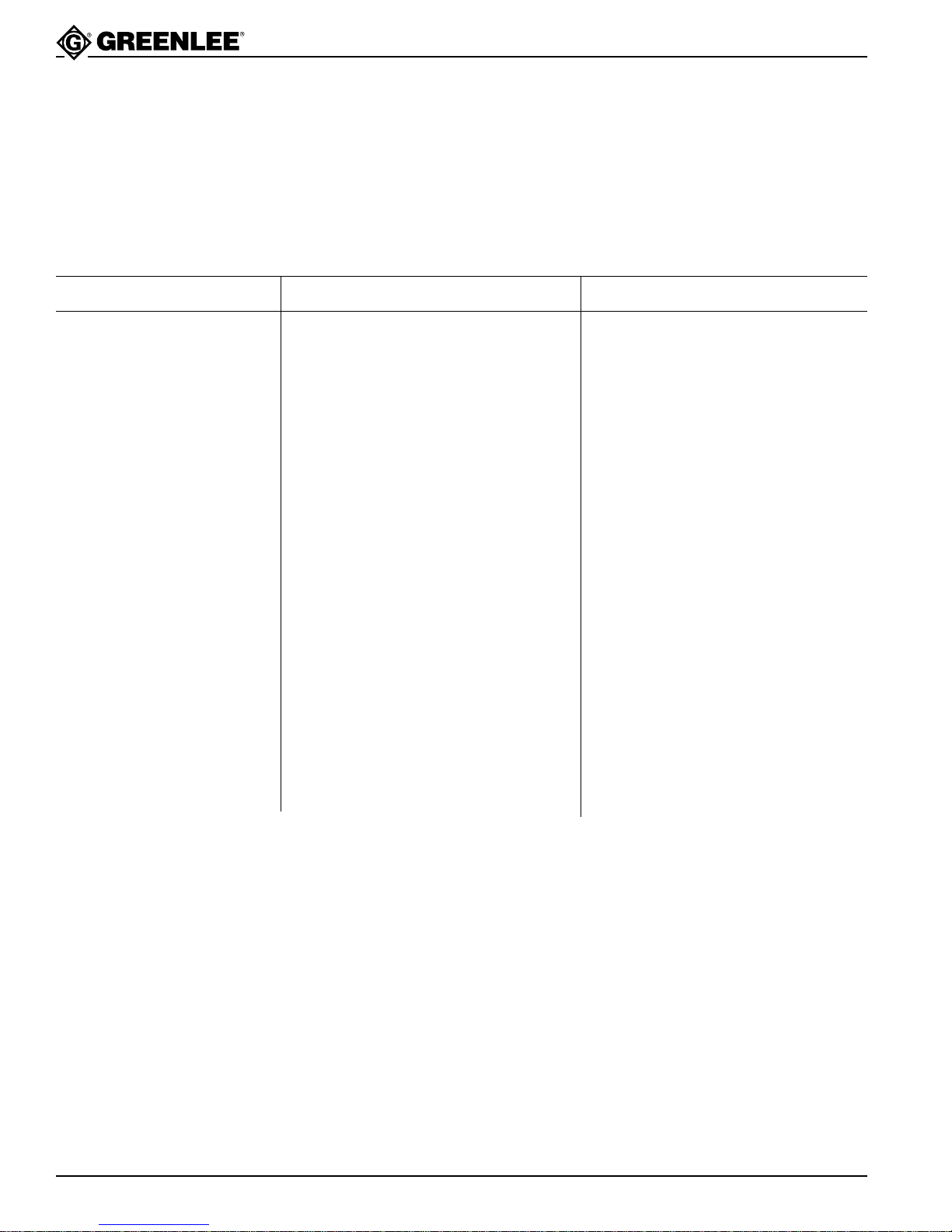

TYPE H.P. VOLTS 100 P.S.I. 10,000 P.S.I.

PUMPING CAPACITY

MODEL (CU. IN. PER MIN.) HEIGHT WEIGHT

940-PS

Series

MOTOR

AC 1 115/230 150 30 20

9

/

16

" 10

1

/

2

x 12" 71 lbs. approx.

BASE

DIAMETER