H36.0.12.6C-09 Operating Manual GMH 3691 page 7 of 12

7 Notes to Special Functions

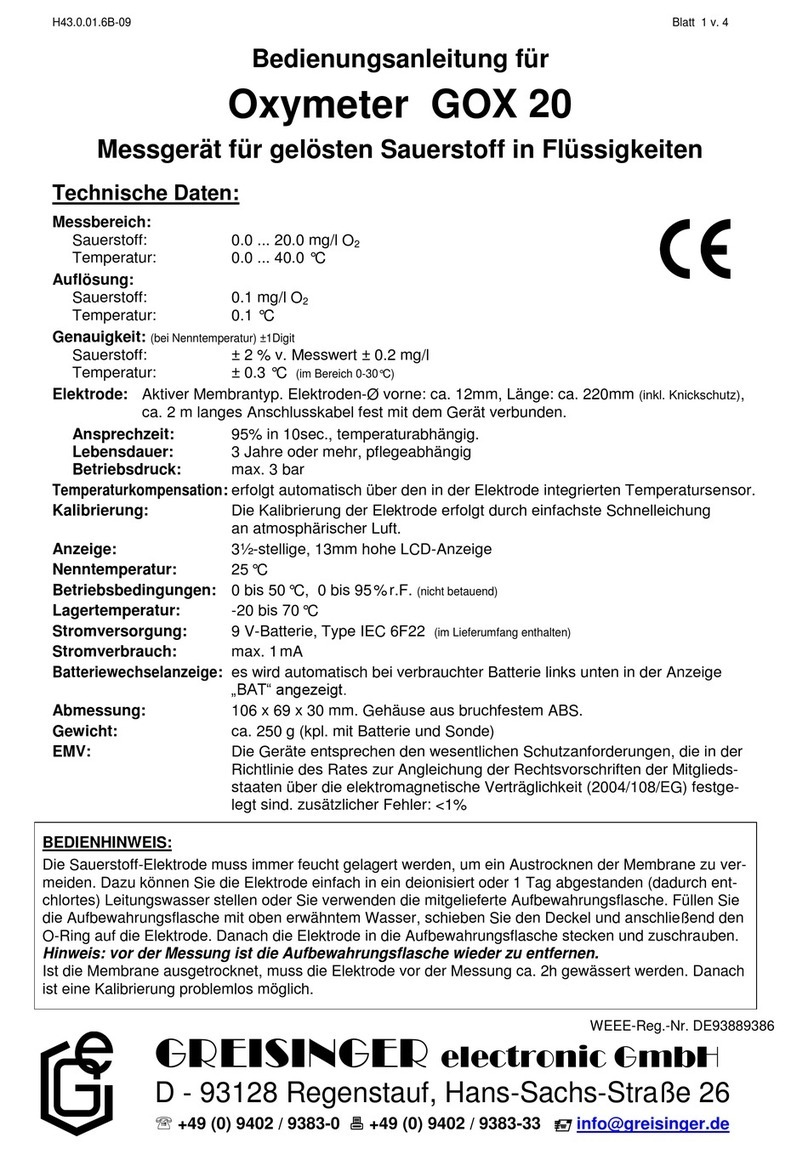

7.1 Input of absolute pressure ('P.Abs')

To get most accurate measurings the absolute pressure should be inspected both before calibration and measuring.

The determining pressure is the actual pressure at the sensor membrane. Keep in mind that gas flows may change

the absolute pressure at the membrane and therefore may cause measuring errors!

7.2 Zero Displacement (’Offset’) temperature

A zero displacement can be carried out for the temperature measurement.

temperature displayed = temperature measured - offset

Standard setting: ’off’ = 0.0°, i.e. no zero displacement will be carried out. The zero displacement is mainly used to

compensate for sensor deviations. Unless ’off’ is set, this value will be displayed shortly after the device is switched on.

7.3 Alarm function

If the alarm function has been activated (p.r.t. configuration), an alarm will be issued under the following circum-

stances:

•measuring value smaller or equalling lower alarm limit 'AL.Lo'

•measuring value higher or equalling upper alarm limit 'AL.Hi'

•no electrode connected or error in sensor

•measuring values exceeding/falling below measuring ranges

•battery voltage too low

•error in device ('Err.7')

The alarm function is supported by the interface, thus, it can easily be monitored by a computer connected.

7.4 Base Address (’Adr.’)

Using the interface converter GRS3105 it is possible to connect several instruments to a single interface. As a pre-

condition the base addresses of all devices must not be identical. In case several devices will be connected via one

interface make sure to configurate the base addresses accordingly. Channel 1 will be addressed by the base ad-

dress set, channels 2 and 3 will have the following addresses.

(Example: base address 21 - channel 1 = 21, channel 2 = 22, channel 3 = 23)

8 Oxygen Measuring - please note

When measuring gases, please consider the following:

Calibration and measuring are depending of the absolute pressure at the sensor!

Therefore check absolute pressure before calibration and measuring.

Sensor temperature and gas temperature should be the same!

Temperature differences may cause additional measuring errors! It may take from several minutes up to

several hours (depending on the measurement setup) until both temperatures are adjusted.

Temperature differences may cause additional measuring errors! In worst case conditions it may take up to

several hours until both temperatures are adjusted. A suitable flow of the gas around the sensor element in-

creases the adjustment significantly..

8.1 Application of the different sensor types GGO 369 / 370 and GOO 369 / 370

GGO 369 / 370 (closed sensor)

For measurements at atmosphere and in systems without over or under pressure the GGO ... is sufficient.

Additionally the GGO ... can be screwed impermeable to systems with a known pressure. (Attention: please note the

specified operating pressure for one-sided strain).

The actual pressure has to be entered (p.r.t. ‚Configuration‘). The pressure will be compensated and no additional

mesuring error will occur.

GOO 369 / 370 (open sensor)

The sensor is equipped with drillings at the end and because of its special construction the measuring gas streams

optimally around the sensor. No pressure can appear while gas blows to the sensor, which otherwise would result in

erroneous measurings. At ‚P.Abs‘ the atmospheric pressure has to be entered.

The temperature compensation speed of the sensor also is optimized by this design. The measuring gas escapes

into the air. Especially the measuring of gases from compressed gas bottles, where the expansion of the gas leaving

the bottle lowers the temperature, is optimized with regard to the temperature compensation and pressure errors.

The gas flow should be chosen in a suitable range, where no overpressure can happen, esp. if the sensor is con-

nected directly to the source e.g. by means of a tube.