Table of Contents

INTRODUCTION............................................... 3

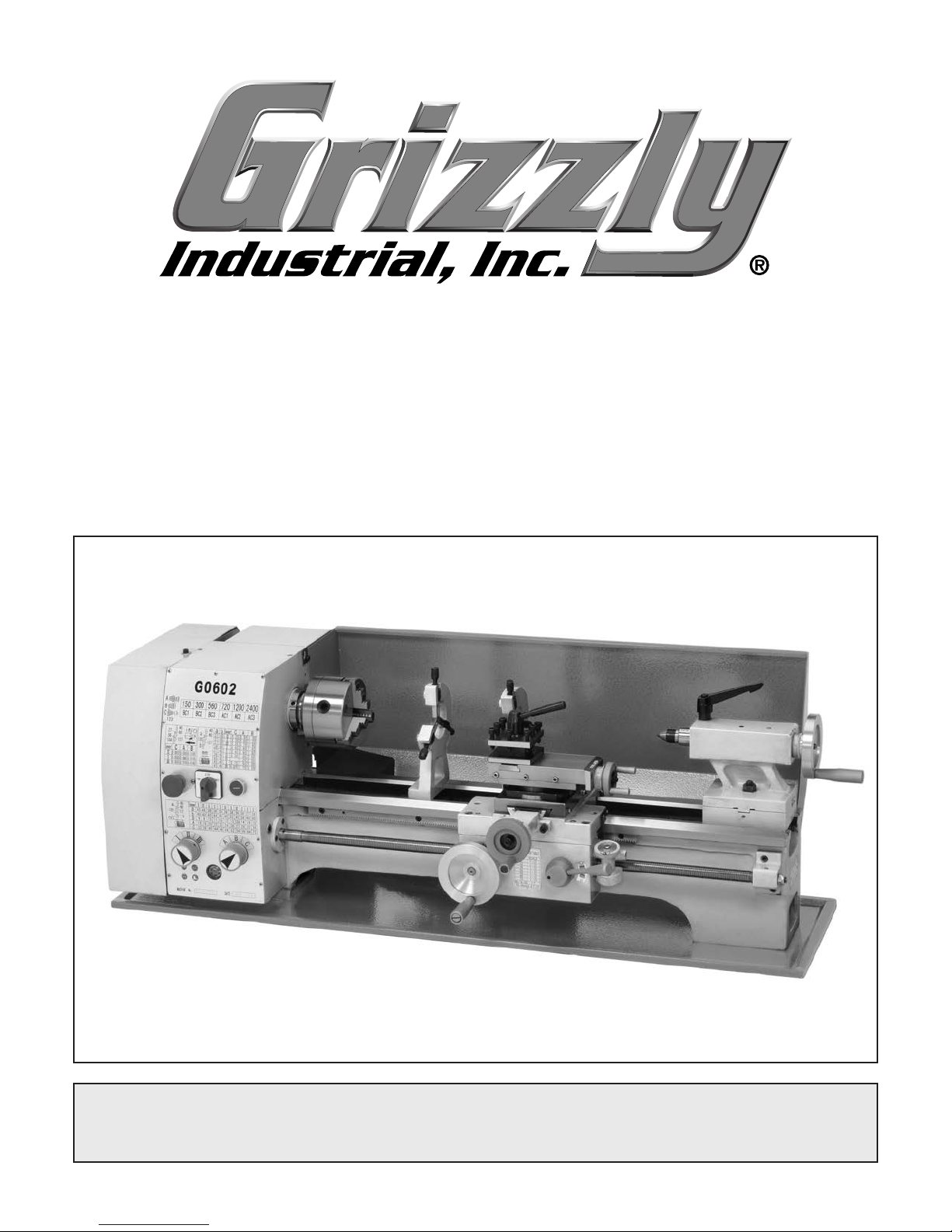

Machine Description ...................................... 3

Contact Info.................................................... 3

Manual Accuracy ........................................... 3

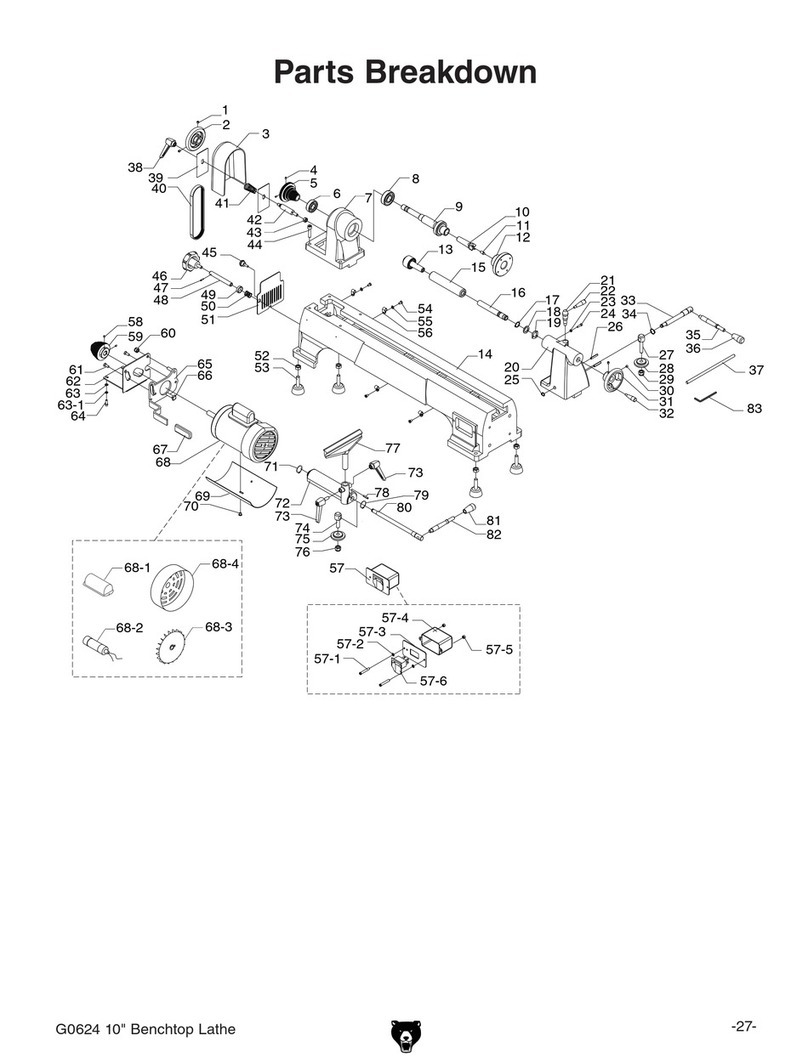

Model G0602 Identification ............................ 4

Model G0752 Identification ............................ 5

Controls & Components ................................. 6

Model G0602 Control Panel ............................... 6

Model G0752 Control Panel ............................... 6

Quick Change Gearbox ...................................... 6

Carriage .............................................................. 7

Tailstock .............................................................. 7

Change Gears, Pulleys, V-Belt ........................... 7

Machine Data Sheet ...................................... 8

SECTION 1: SAFETY..................................... 10

Safety Instructions for Machinery ................ 10

Additional Safety for Metal Lathes ............... 12

Glossary of Terms ....................................... 13

SECTION 2: POWER SUPPLY ...................... 14

Availability ......................................................... 14

Full-Load Current Rating .................................. 14

Circuit Requirements ........................................ 14

Grounding & Plug Requirements ...................... 15

Extension Cords ................................................ 15

SECTION 3: SETUP ....................................... 16

Unpacking .................................................... 16

Needed for Setup ......................................... 16

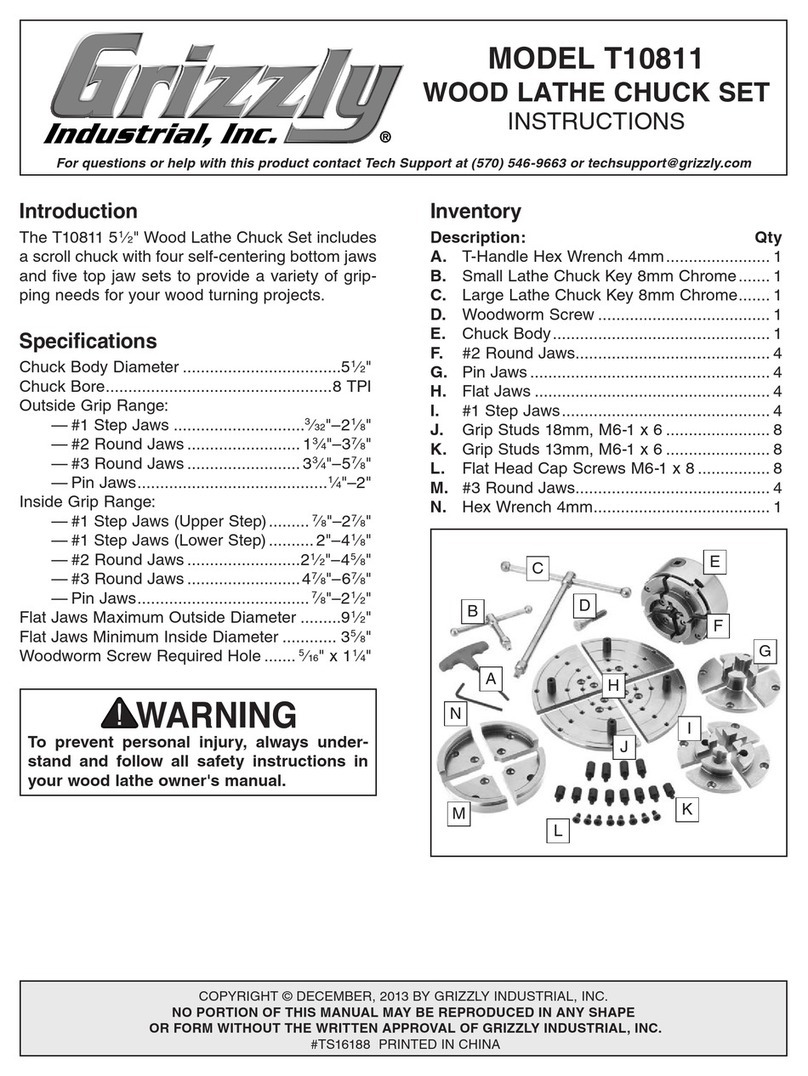

Inventory ...................................................... 17

Cleanup ........................................................ 18

Site Considerations ...................................... 19

Lifting & Placing ........................................... 20

Leveling & Mounting .................................... 21

Leveling ............................................................. 21

Mounting ........................................................... 21

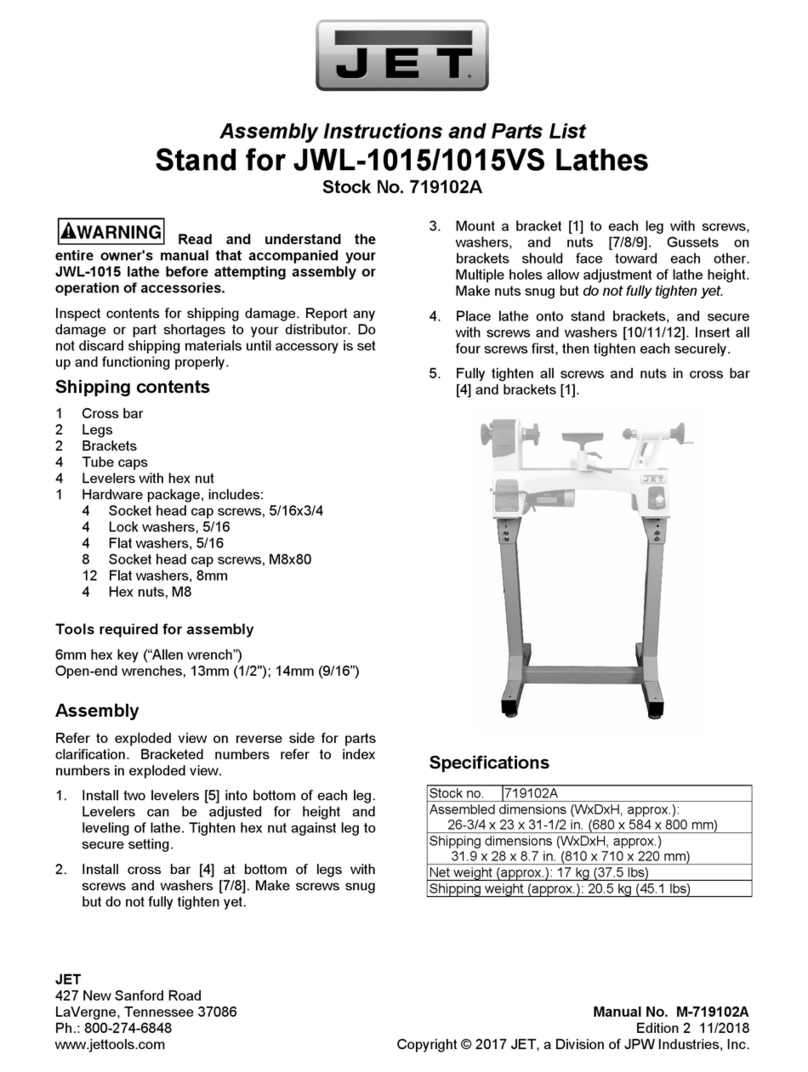

Assembly ..................................................... 22

Lubricating Lathe ......................................... 22

Power Connection........................................ 22

Connecting Power ............................................. 22

Disconnecting Power ........................................ 22

Test Run ...................................................... 22

Spindle Break-In .......................................... 24

Recommended Adjustments ........................ 24

SECTION 4: OPERATIONS ........................... 25

Operation Overview ..................................... 25

Chuck & Faceplate Mounting....................... 26

Installation & Removal Devices ................... 26

Chuck Installation......................................... 27

Chuck Removal............................................ 28

Changing Jaw Set ........................................ 28

Scroll Chuck Clamping ................................ 29

4-Jaw Chuck ................................................ 30

Faceplate ..................................................... 31

Tailstock ....................................................... 32

Positioning Tailstock ......................................... 32

Using Quill ......................................................... 32

Installing Tooling ............................................... 32

Removing Tooling ............................................. 33

Offsetting Tailstock ........................................... 33

Aligning Tailstock to Spindle Centerline ........... 34

Centers ........................................................ 36

Dead Centers .................................................... 36

Live Centers ...................................................... 36

Mounting Dead Center in Spindle ..................... 36

Removing Center from Spindle ......................... 37

Mounting Center in Tailstock ............................ 37

Removing Center from Tailstock ...................... 37

Mounting Workpiece Between Centers ............ 38

Steady Rest ................................................. 38

Follow Rest .................................................. 39

Carriage & Slide Locks ................................ 39

Compound Rest ........................................... 39

Four-Way Tool Post ..................................... 40

Installing Tool .................................................... 40

Aligning Cutting Tool with Spindle Centerline ... 40

Manual Feed ................................................ 41

Spindle Speed.............................................. 42

Determining Spindle Speed .............................. 42

Setting Spindle Speed ...................................... 42

G0602 Configuration Examples ........................ 42

G0752 Configuration Example .......................... 43

Power Feed.................................................. 44

Setting Power Feed Rate .................................. 45

Threading ..................................................... 46

Headstock Threading Controls ......................... 46

Apron Threading Controls ................................. 47

Thread Dial Chart ............................................. 47