Table of Contents

Introduction············································· 6

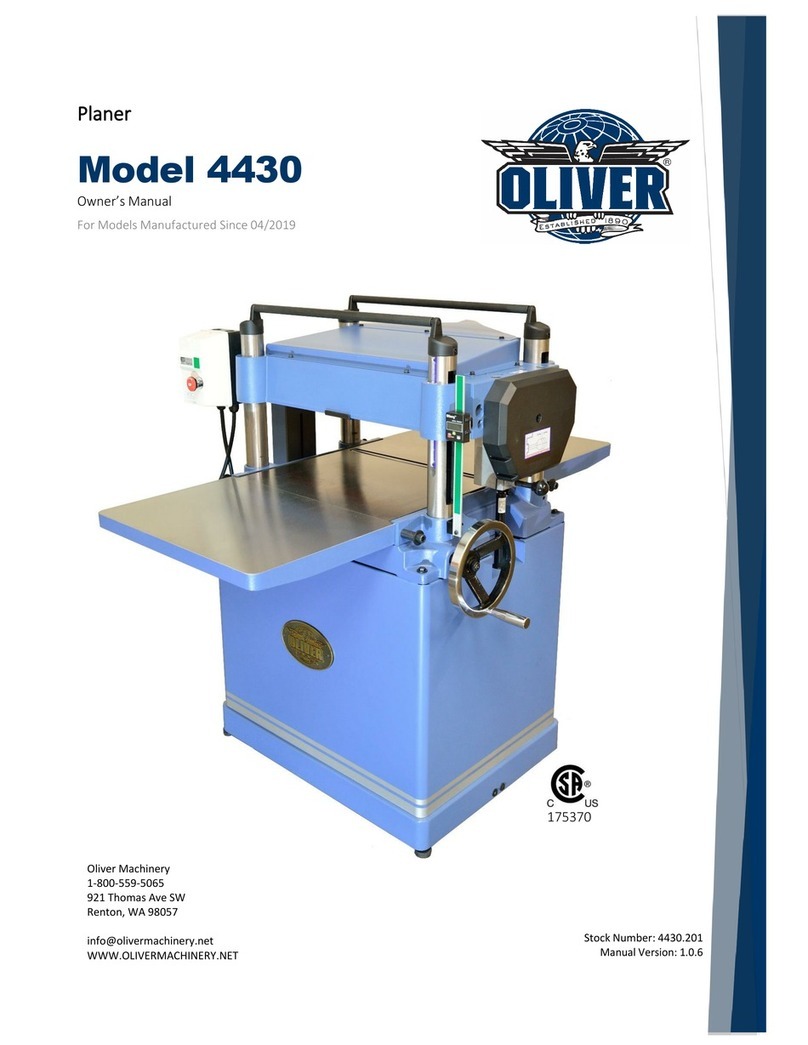

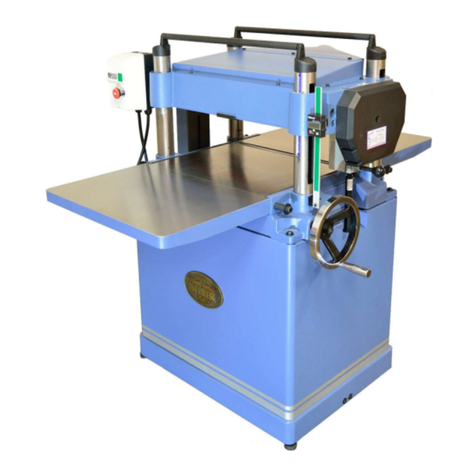

Specifications ·········································· 7

Quick View ·················································7

Product Dimensions····································7

Shipment Info·············································7

Electricals ···················································7

Motor ························································8

Planer Capacity and Performance ···············8

Cutterhead and Headstock ··························8

Measurements ···········································8

Table ··························································9

Safety·························································9

Others ························································9

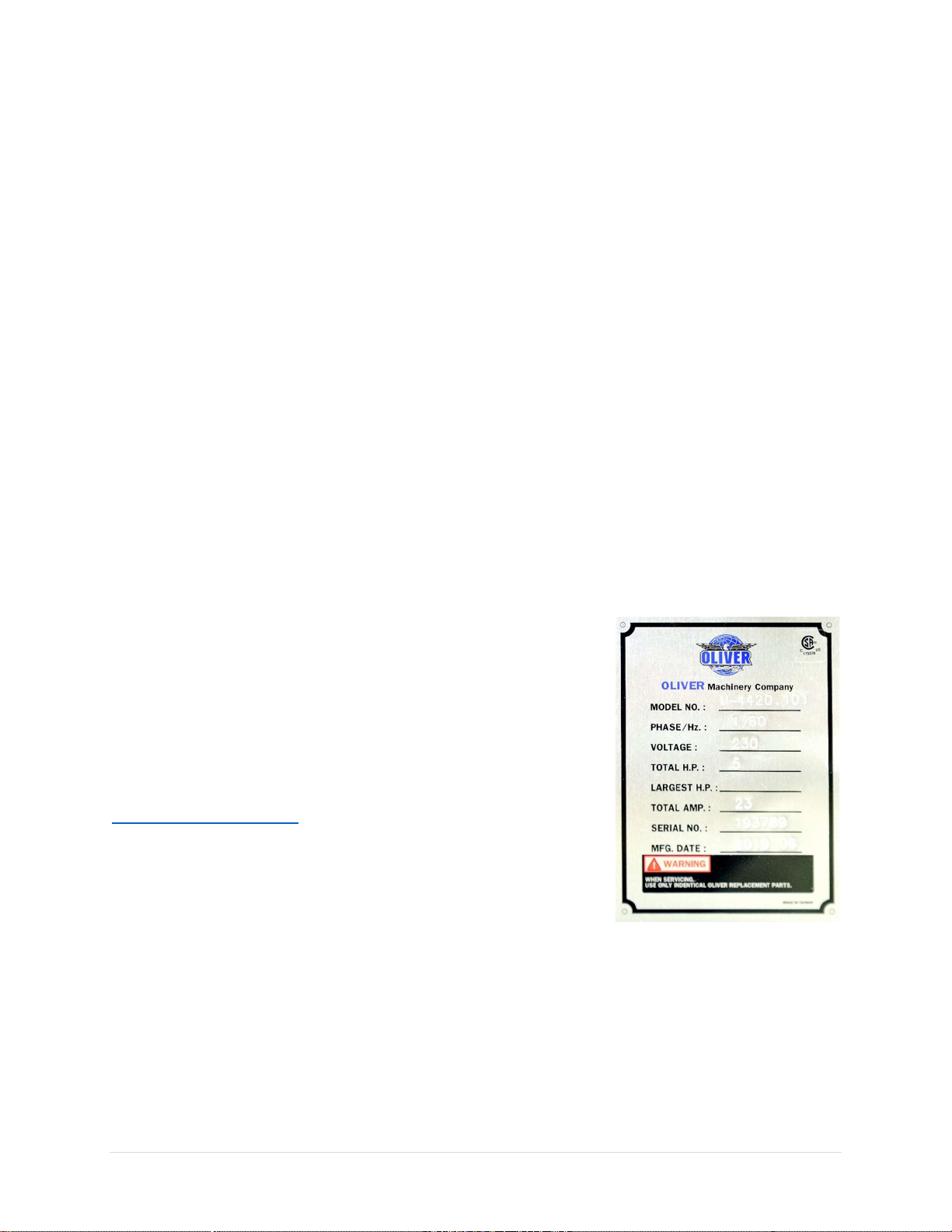

Identification ··········································10

Safety ·····················································12

General Safety Guidelines ························· 12

Safety Guidelines Specific to Planer··········· 13

Electricals ···············································15

Minimum Circuit Size Required for Model

4420 Planer ·············································· 15

Grounding ················································ 15

Electrical Wiring ······································· 15

Setup ······················································17

Shop Preparation······································ 17

Space Requirement ········································· 17

Load Limits ······················································ 17

Electricals ························································ 17

Lighting ···························································· 17

Safety Labels ··················································· 17

Dust Collection ················································ 17

Receiving ·················································· 18

Unboxing ················································· 18

Inventory ················································· 19

Removing Machine from Crate ·················· 20

Cleaning ··················································· 21

Assembly ················································· 21

Installing Height Adjustment Handwheel ······· 22

Installing Dust Hood ········································ 23

Installing Extension Tables ······························ 24

Installing Power Switch ··································· 25

Dust Collection ········································· 26

Wiring and Grounding ······························ 27

Wiring Instructions ·········································· 27

Break-in Period ········································· 27

Controls and Components ······················ 28

ON / OFF Switches ···································· 28

Table Height Adjustment ·························· 28

Table Height Locking Knobs ······················ 28

Table Height Scale ···································· 28

Digital Readout (DRO) ······························· 29

DRO Calibration ··············································· 33

Feed Rate Control ····································· 30

Components for Planing Wood ················· 31

Test Run ··················································· 32

Operation ·············································· 34

Step 1: Preparation ··································· 34

Step 2: Setting Depth of Cut and Feed Rate35

Step 3: Select Feed Direction ····················· 36

Step 4: Planing Wood to Desired Thickness36

Common Cutting Problems ······················· 38

Snipe ································································ 38

Chipping ·························································· 38

Indentation ······················································ 38

Fuzzy Grain ······················································ 38

Accessories ············································ 39

Cutter Inserts ··········································· 39

Touchup Paint ·········································· 39

Maintenance ········································· 40

Maintenance Schedule ····························· 40