10 OM-DH/DHT

Operation

WARNING

WHEN TILTING KETTLE:

1) WEAR PROTECTIVE OVEN MITT AND

PROTECTIVE APRON.

2) USE DEEP CONTAINER TO CONTAIN

AND MINIMIZE PRODUCT SPLASHING.

3) PLACE CONTAINER ON STABLE,

FLAT SURFACE, AS CLOSE TO

KETTLE AS POSSIBLE.

4) STAND TO RIGHT OF KETTLE WHILE

POURING — NOT DIRECTLY IN POUR

PATH OF HOT CONTENTS.

5) POUR SLOWLY, MAINTAINING

CONTROL OF KETTLE, AND RETURN

KETTLE BODY TO UPRIGHT POSITION

AFTER CONTAINER IS FILLED OR

TRANSFER IS COMPLETE.

6) DO NOT OVERFILL CONTAINER.

AVOID SKIN CONTACT WITH HOT

CONTAINER AND ITS CONTENTS.

WARNING

AVOID ALL DIRECT CONTACT WITH HOT

SURFACES AND HOT FOOD OR WATER

IN THE KETTLE. DIRECT CONTACT

COULD RESULT IN SEVERE BURNS.

CAUTION

DO NOT TILT KETTLE WITH LIFT-OFF

COVER IN PLACE. COVER MAY SLIDE

OFF, CAUSING INJURY TO OPERATOR.

the set temperature is accepted, it may be changed at any time by

pressing the MANUAL button and resetting the temperature using the

same process above.

i. HIGH TEMP button – Used to set operating temperature of the kettle

at a preset high intensity (default = 7). Can be pressed at any time

during operation of the unit to change the set temperature to the

preset value except when there is an active TIMER enabled.

1. TIMER button - once the appropriate set temperature is

selected using the HIGH TEMP, MANUAL or LOW TEMP buttons;

a countdown timer can be set to remind the user when the

cooking process is completed. Range – 1 minute to 10 hours

2. When the timer expires:

a. the set temperature will automatically change to the LOW

TEMP setting and will continue at this setting until the

user changes the temperature via MANUAL or HIGH TEMP

buttons

b. An audible alarm will notify the user that attention is

required, the alarm will continue to sound until the user

presses the TIMER button.

3. An active timer can be cancelled by pressing and holding the

TIMER button for 5 secs

4. Set temp can be changed during an active timer by pressing

the MANUAL button and adjusting the set temp using the

Temperature knob and display

5. HIGH TEMP and LOW TEMP presets cannot be used to change

the setpoint once a TIMER has started.

j. READY alarm – The control will sound 3 beeps when the unit has

reached within 20 degrees of set point during pre-heat and when a

higher set temperature is selected.

k. Crank tilt - a handle controls the worm and gear mechanism that

smoothly tilts the kettle body and holds it in the desired position.

B. Operating Procedure

1. To Start Kettle Heating:

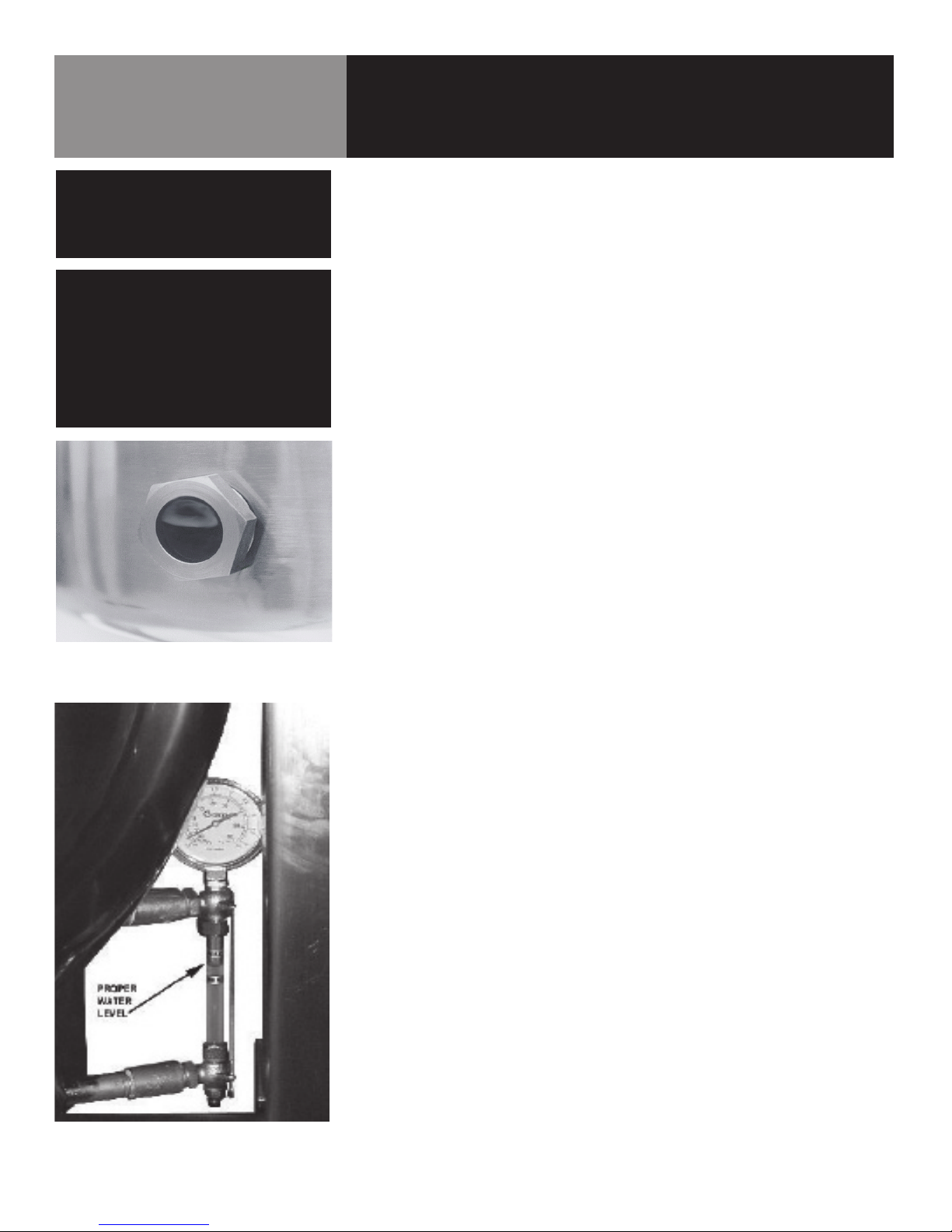

a. EVERY DAY make sure that the jacket water level in the middle of

the sight glass. If the level is too low, see “Jacket Filling and Water

Treatment” on page 16.

b. Check the pressure/vacuum gauge. If the gauge does not show 20

to 30 inches of mercury (Hg) vacuum (that is a reading of 20 to 30

below 0 atmospheric pressure), see “Jacket Vacuum” on page 16.

c. Do not attempt to light any burner with a flame.

d. Turn the manual gas valve ON (align handle with gas line).

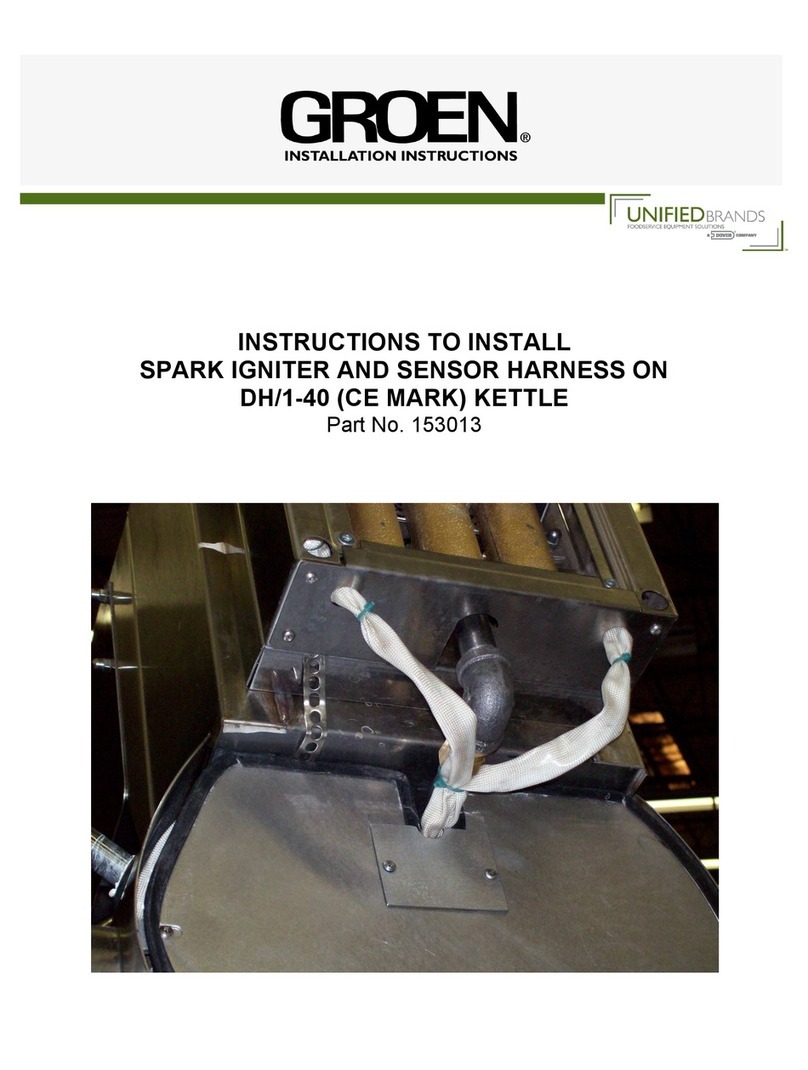

e. Turn rocker (on-off) switch ON. The electronic ignition will attempt to

light the pilot for 90 seconds, or until it is lit. Once lit proceed to step

two.

f. Turn controller to desired setting. The main gas burner will ignite, and

will cycle to maintain the set temperature. The heat indicator light will

come on.

g. If the unit does not light, turn it off and wait five minutes. Then follow

the instructions again.