OM-AH

7

9. The internal gas lines of the unit were cleaned and

closed off with a gas cock before the unit was

shipped from the factory. Free all external gas lines

of lint, dirt, metal chips, sealant, grease, oil, and

other contaminants, before you connect the lines to

the kettle.

10. Connect the gas cock of the kettle to the gas service

main with 3/4 inch IPS line or approved equivalent

11. Installation must conform with local codes, or in the

absence of local codes, with the National Fuel Gas

Code, ANSI Z 223.1-1988 (or latest edition). The

unit should be installed in an adequately ventilated

room with a provision for adequate air supply. The

best ventilation will utilize a vent hood and exhaust

fan with no direct connection between the vent duct

and the flue. Do NOT obstruct the flue or vent duct

after installation.

In Canada, the installation must conform to the

CAN/CGA B149 Installation Codes for Gas Burning

Appliances and Equipment and/or local codes.

12. Adequate space for proper service and operation is

required. Do NOT block any air intake spacings to

the combustion chamber or obstruct the air flow by

piling or stacking anything near the kettle.

13. After the kettle has been connected to the gas

supply, all gas line joints must be checked for leaks.

DO NOT USE A FLAME TO CHECK FOR LEAKS.

A thick soap solution or other suitable leak detector

should be employed.

14. For a unit on casters, complete connection to the

gas supply with connectors that comply with the

standard for connectors for moveable gas

appliances, ANSI Z21.69 — latest edition. Restrain

movement of the unit by attaching a cable or chain

to the eyelet (provided at the back of the frame) and

anchoring the cable or chain to the wall or floor.

Make the length and location of the cable such that

the unit cannot pull on the gas connection while the

cable is connected.

15. The appliance and its individual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 PSIG (3.48 kPa). The

appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less

than 1/2 PSIG (3.48 kPa)

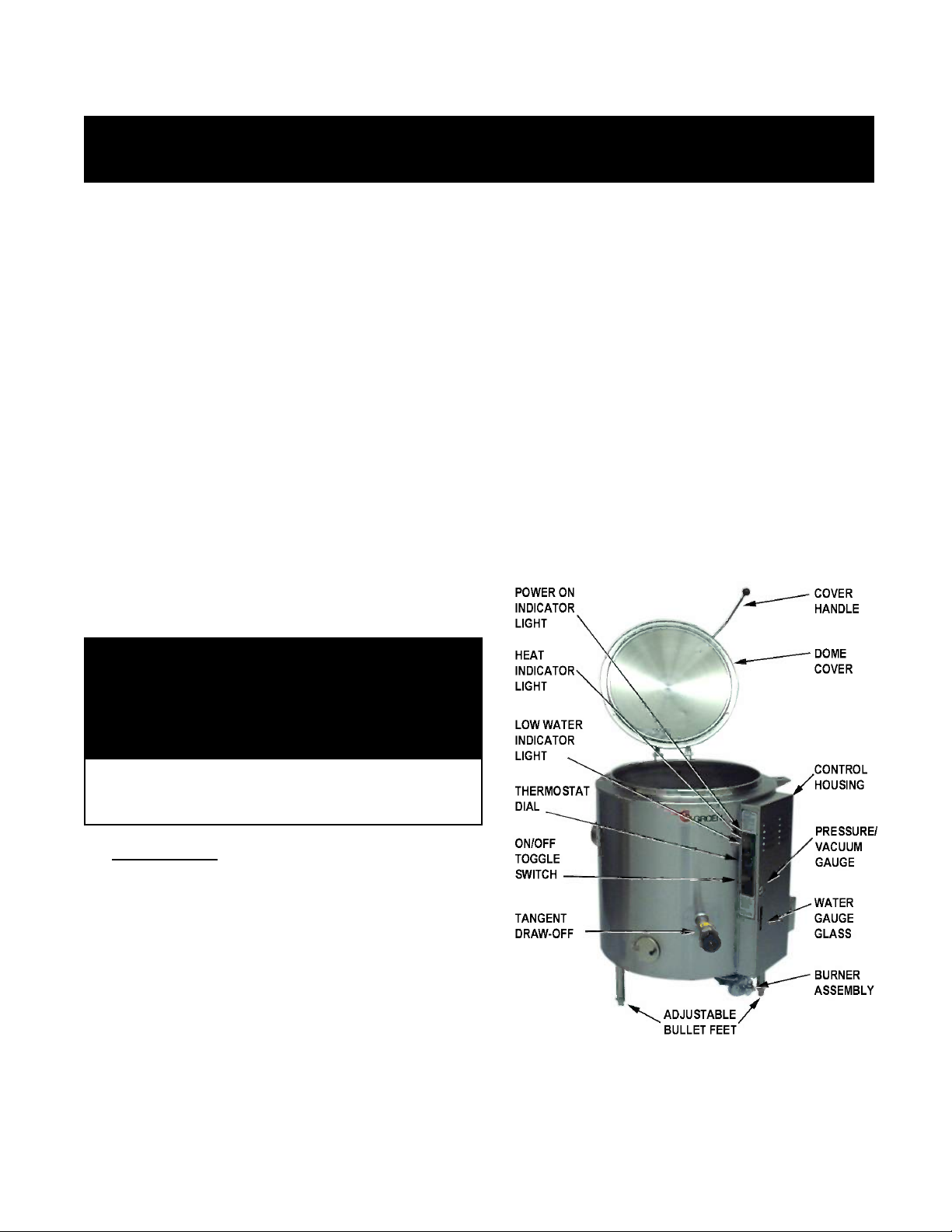

16. Check the following points to confirm that your AH

kettle has been installed properly.

electrical, or gas type change must be approved

by the Groen Food Service Engineering

Department.

a. Enough room between the kettle and nearby

objects for cleaning and service.

b. Minimum clearance of 6 inches from sides

and 6 inches from draft diverter.

c. Unit vented to a hood or chimney. (Not attached

to a vent.

d. Kettle level.

e. Correct amount of water in the jacket.

f. Pressure relief safety valve outlet pointed down.

g. Connected with a waterproof, 115 volt, 15

amp supply of electric power in accordance

with electrical codes.

h. Gas lines cleaned before connection.

i. Gas connected with 3/4 inch pipe or

equivalent

j. Gas line joints checked for leaks.

k. No obstruction to air supply or venting.

B. Initial Start-Up

After the kettle has been installed, the installer

should test to ensure that it is operating correctly.

1. Remove literature and packing materials from

inside and outside of the unit.

2. Install the TDO valve.

3. Put a small amount of water into the kettle.

4. Verify that kettle water level is normal and that

kettle is holding vacuum in jacket. Correct if not.

5. Make sure the supplies of gas and electric

power are on.

6. Follow the Start Kettle Heating instructions in the

Operation section of this manual. Begin heating

the water at the highest thermostat setting. The

indicator light should come on and heating

should continue until the water boils.

7. To turn off the unit, follow “To Stop Kettle

Heating” in “Operating Instructions,” below.

If the kettle functions as described, it is ready for

use. If the unit does not operate as designed,

contact authorized Groen Service Agent.

8. Provide 115 VAC, 60 HZ, 1 PH, 15 AMP

electrical service for standard unit. Unit may be

equipped for alyternate electrical service of 208

VAC or 240 VAC, as ordered. Use 1/2 inch

waterproof conduit and waterproof connections.

Observe local codes and/or The National

Electrical Code in accordance with ANSI/NFPA

70 - latest edition. AN ELECTRICAL GROUND

IS REQUIRED. The electrical schematic is

located on the inside of the service panel.

In Canada, provide electrical service in

accordance with the Canadian Electrical Code,

CSA C22.1 Part 1 and/or local codes.

Any mechanical,

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor