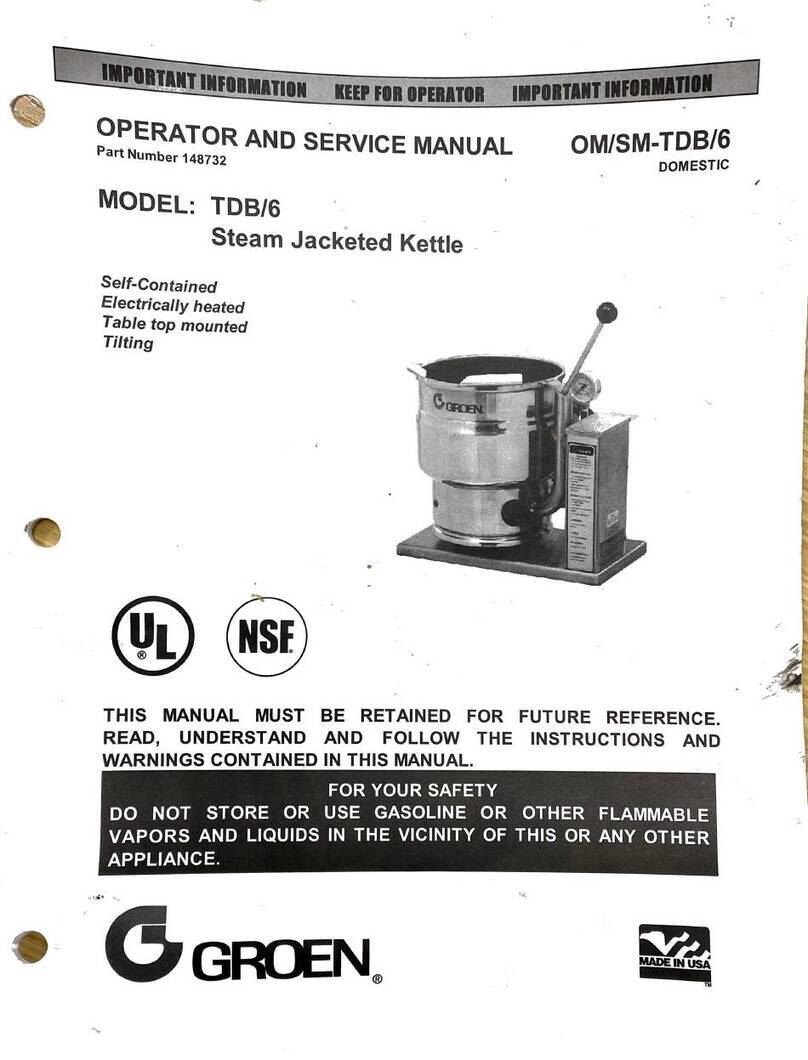

10 OM/SM-EE-CE

Tips for Use.

a) Allow for displacement of the three baskets

and product. This may mean only filling the

kettle half way. Test baskets and product

displacement with the kettle OFF, and with

cold water in the kettle.

b) Load baskets on a level, stable work surface.

c) Lift loaded baskets with both hands. Get

help from another person if the basket is too

heavy for safe handling.

d) Slowly lower product into kettle and securely

hook the basket to the “Y” frame.

e) When removing baskets with cooked

product, lift straight up, ensuring basket

bottoms clear the kettle rim. Wear protective

oven mitts and protective apron.

f) Allow hot water to fully drain from product,

before moving basket away from the kettle.

Do not rest baskets on kettle rim or pouring

lip. If baskets are too heavy for one

individual to lift and safely move, get help.

Remove product immediately from basket

into another container, being sure to avoid

contact with hot product and hot basket or:

g) Place baskets with food on a stable, flat

surface, inside a solid steamer or bake pan,

to catch any remaining hot water draining

from product.

5.8 To Turn Off the Kettle

5.8.1 Turn the thermostat dial to “OFF.”

5.8.2 Before the unit is serviced, or if it will be off for

a week or more:

a) Set the thermostat to “OFF.”

b) Turn off electric power to the unit at the

circuit breaker or fuse.

CAUTION

DO NOT OVERFILL THE KETTLE WHEN

COOKING, HOLDING OR CLEANING. KEEP

LIQUIDS AT LEAST 2-3” (5-8 cm) BELOW

THE KETTLE BODY RIM TO ALLOW

CLEARANCE FOR STIRRING, BOILING

PRODUCT AND SAFE TRANSFER.

WARNING

OPEN THE KETTLE LID CAREFULLY TO

AVOID STEAM WHICH MAY ESCAPE.

DIRECT CONTACT COULD RESULT IN

SEVERE BURNS.

The following “action-reaction” outline is provided to

help the user understand how the equipment works.

When the operator starts up the kettle by turning the

operating thermostat dial from “OFF” to a desired

setting, the thermostat switch closes. This lights up

the heating indicator light and causes the contactors

to close, allowing power to flow to heating elements.

When the temperature of the steam jacket reaches

the value corresponding to the dial setting, the

thermostat switch opens. This turns off the heating

indicator light and causes the contactors to open,

cutting the power to the heaters.

As soon as the thermostat senses that the kettle is

cooling below the set point, the thermostat switch

closes, the heating indicator light comes on, the

contactors close, and the heaters come on again.

On-off cycling continues, keeping the kettle at the set

temperature. This is why the heating indicator light

cycles on and off during normal operation.

If steam pressure greater than 30 PSIG is generated

in the jacket, the safety valve will open and relieve

the excess pressure.

If the jacket water level gets too low before the

heating elements overheat, the high-limit control will

open and shut off power to the elements until the

kettle cools.

Setting the operating thermostat dial to “OFF” shuts

down all control and heating circuits.

6.0 Sequence of Operation