Glendo Corporation

900 Overlander Road

P.O. Box 1153

Emporia, KS 66801 USA

1-800-835-3519

Fax: 620-343-9640

Tel: 620-343-1084

www.grstools.com

LIT# 132

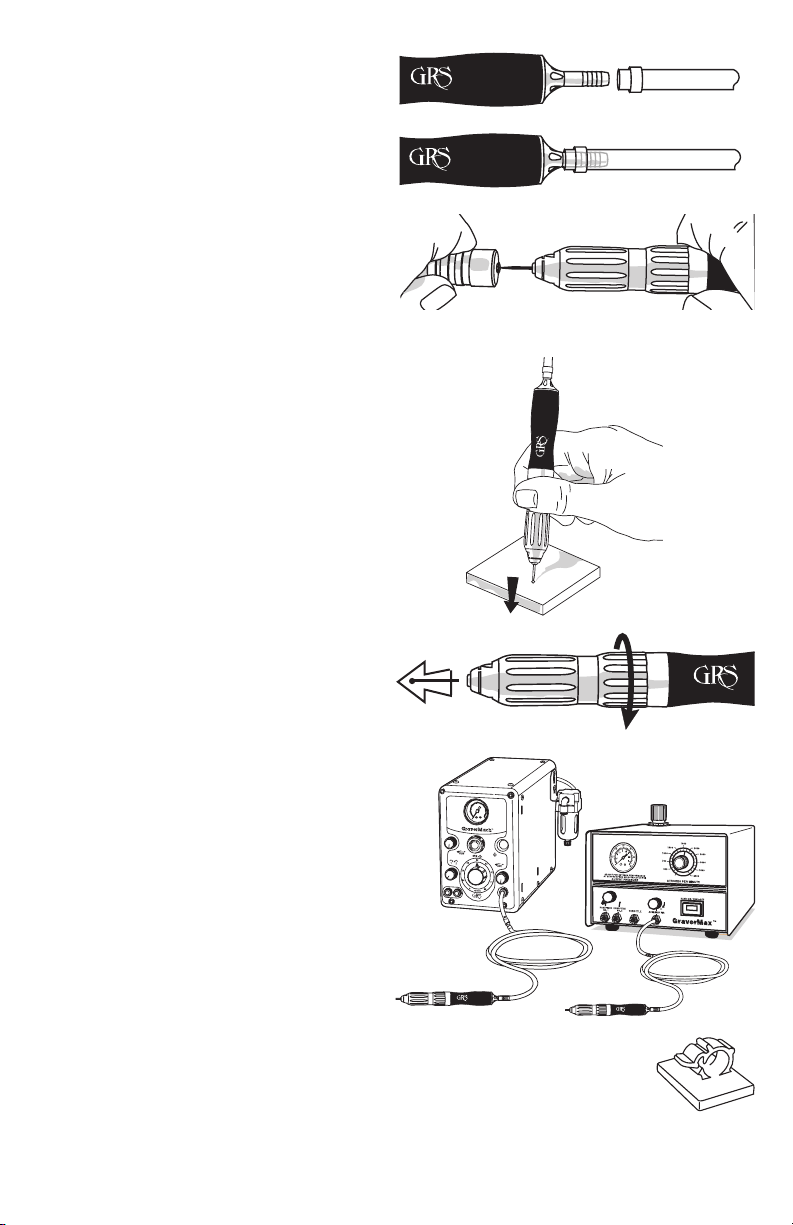

BUR CHECK LIST

• USEONLY.062”dia.(1.6mm)

shank burs.

• DoNOTusebrokenordamagedburs.

You may damage the handpiece or

yourself.

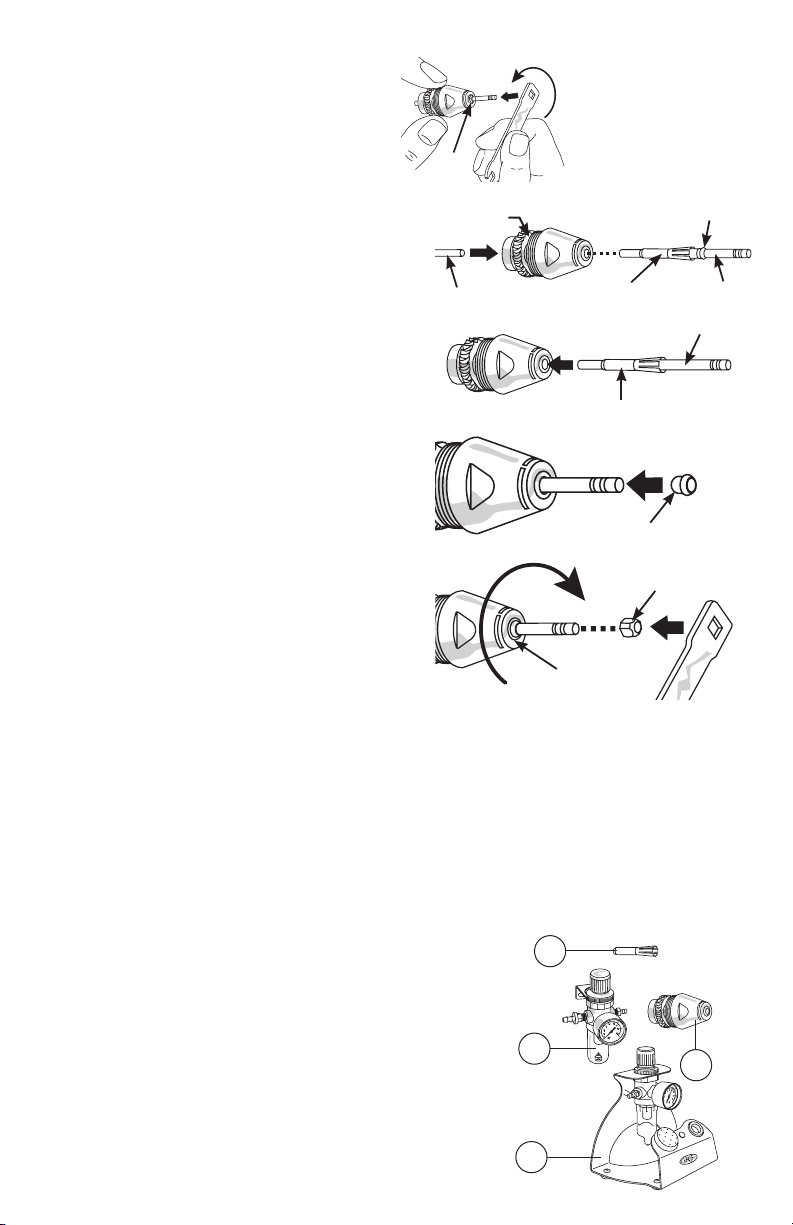

• Before use make sure the bur is properly

seated in the chuck. Press the bur

into the chuck until you feel a slight

“pop.” The bur is then seated. (See

INSERTING BUR fig. 4 - 5)

• Toremoveburturnreleaseringuntil

you feel the bur push outward. (See

REMOVING BUR fig. 6)

• WEARSAFETYEYEGLASSES

LONG-TERM WEAR SYMPTOMS

• BURDOESNOTSEATPROPERLY

If bur is loose after proper seating

procedure is followed, you probably

need a new chuck (collet) #022-365

You may try other brands of burs.

Manufacturing tolerances vary on

shank diameters with budget brands

of burs. Use only quality dental burs.

• ROTARYPOWERISERRATICOR

STOPSCOMPLETELYWHENLIGHT

PRESSURE IS APPLIED

Assuming the air line is clear of

moisture / oil and the turbine is

not clogged, you may need a new

handpiece cartridge, #022-174.

USAGE HINTS

Our customers who use the NSK air tool

get a very long service life out of them. We

have discovered over the 10 or so years

that we have supplied this product to the

engraving industry, if you do not exceed

32-35psi, and use a light touch to allow

the sharp burr to remove the material

(do not force it into the material) they go

for years on a single cartridge. Several

issues have been discovered when using

this handpiece in engraving and jewelry

that go beyond its original design that was

intended for the dental industry.

1. Do not force the bur to cut, use

light wiping motions when removing

background material or cutting a

pattern during layout of a design.

2. Always use a sharp bur, when it

becomes dull, do not push it harder

to make it cut, replace it. This is

especially true when working in steel

or other alloys and hard woods.

3. Do not allow the handpiece to fall onto

a hard surface such as a floor or table

top. This pushes the front and rear

bearings out of position and will cause

very rapid failure.

4. Always gently press the handpiece

against a piece of plastic or hard wood

when seating a burr in the collet. Just

like dropping the handpiece on a hard

surface, these are precision instruments

and must be handled as such.

5. NSK recommends the user remove and

clean the collet every 40 hours of use

with alcohol and a q-tip.

NSK warranties it’s air handpieces for 90

days. This does not include failures due to

misuse or miss-application.