Table of Contents iii

Table of Contents

CHAPTER 1 - BEFORE YOU BEGIN..................................................................................5

INTRODUCTION....................................................................................................................5

SAFETY ..............................................................................................................................5

UNPACKING AND TAKING INVENTORY.....................................................................................6

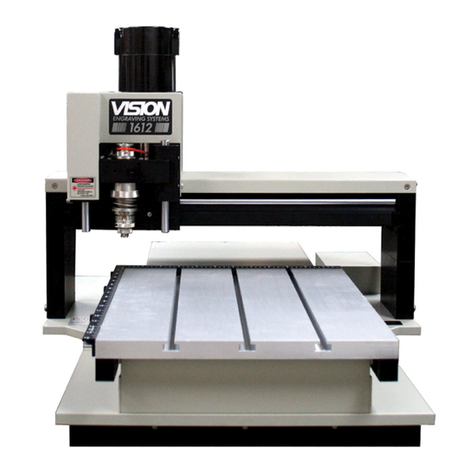

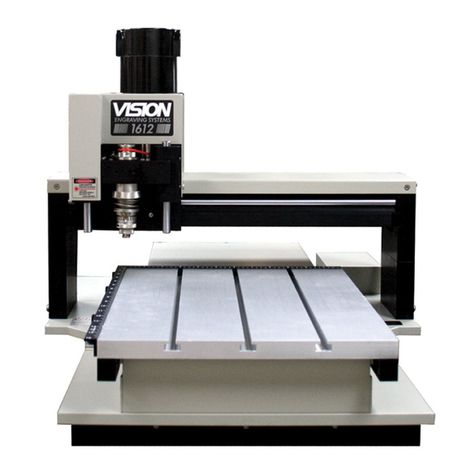

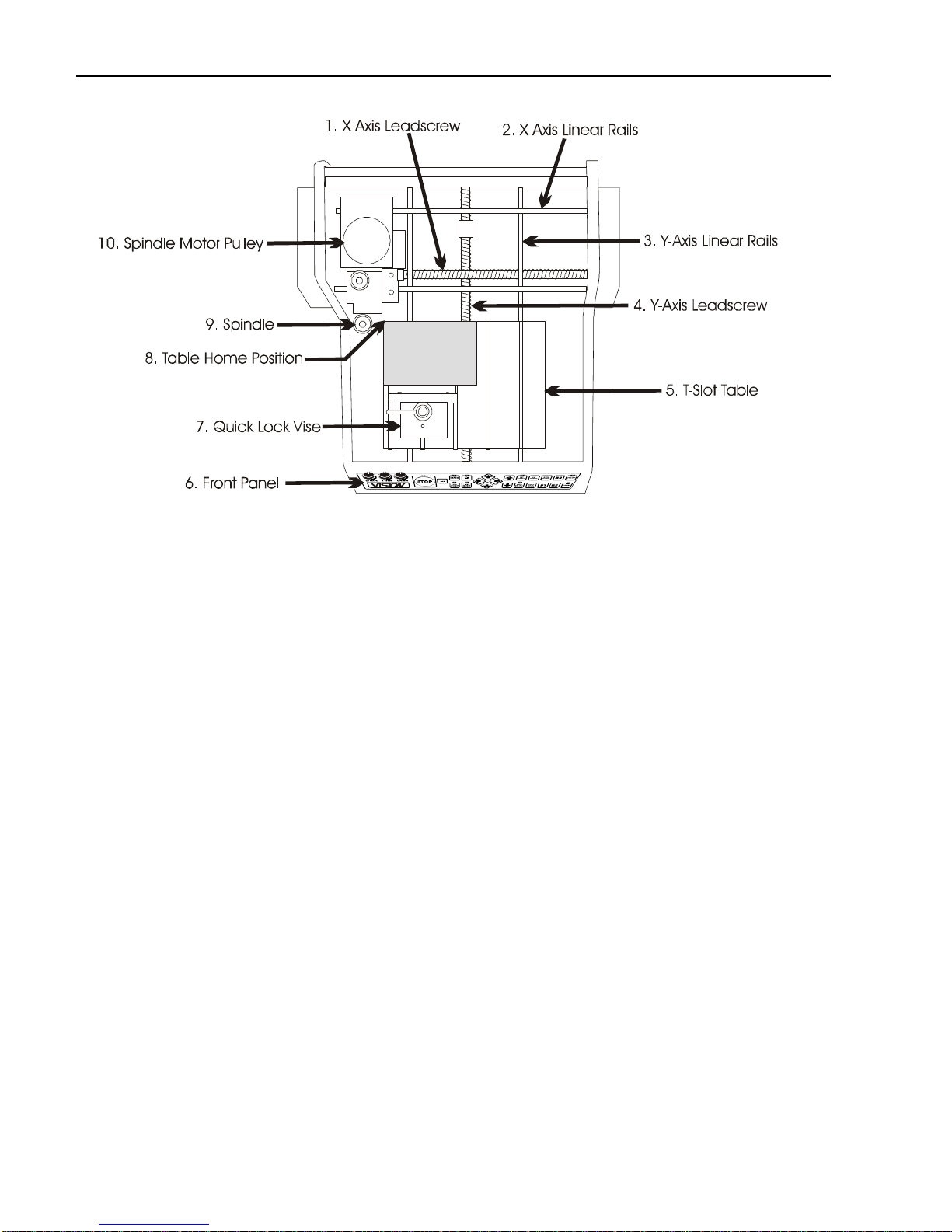

MACHINE DESCRIPTION &TERMINOLOGY ..............................................................................7

CHAPTER 2 - INSTALLATION .........................................................................................13

SOFTWARE INSTALLATION ..................................................................................................13

CONNECTING THE TABLE....................................................................................................19

CONFIGURING THE COMPUTER ...........................................................................................28

CHAPTER 3 - OPERATIONS............................................................................................29

THE FRONT PANEL ............................................................................................................29

HOLDING DOWN MATERIAL..................................................................................................34

DIAMOND DRAG ENGRAVING ..............................................................................................37

ROTARY ENGRAVING .........................................................................................................39

BURNISH ENGRAVING.........................................................................................................41

CHAPTER 4 - OPTIONAL ACCESSORIES......................................................................45

CLAMPING DEVICES...........................................................................................................45

VACUUM CHIP REMOVAL SYSTEM .......................................................................................49

CHAPTER 5 - MAINTENANCE.........................................................................................51

REMOVING CHIPS ..............................................................................................................51

LUBRICATION.....................................................................................................................52

CHANGING THE MOTOR BELT..............................................................................................54

CHANGING THE MOTOR BRUSHES.......................................................................................56

CLEANING THE FAN FILTER.................................................................................................59

REPLACING THE EXTERNAL FUSE........................................................................................60

CHAPTER 6 - TROUBLESHOOTING ...............................................................................63

ENGRAVING PROBLEMS......................................................................................................63

MECHANICAL PROBLEMS....................................................................................................66

INDEX................................................................................................................................59