IContents

I

© 2006 Vision Engraving Systems

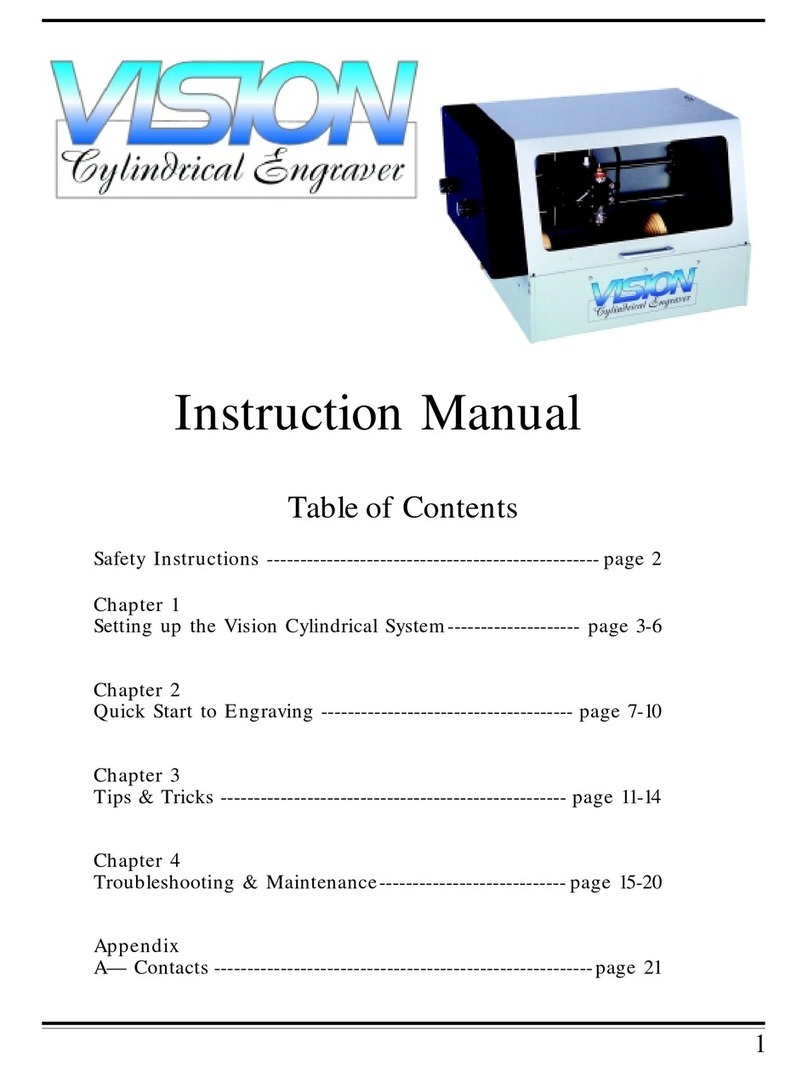

Table of Contents

Part I Before you begin 2

...................................................................................................................................2About This Manual

...................................................................................................................................2Safety

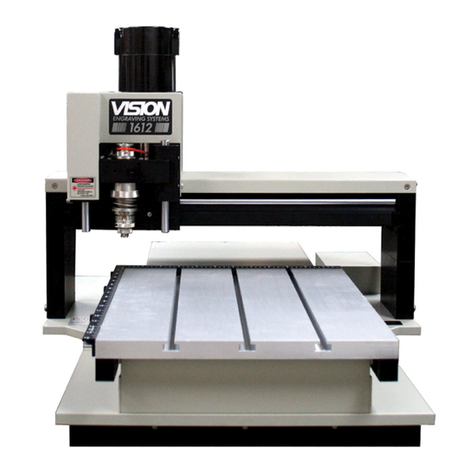

...................................................................................................................................3Unpacking and Taking Inventory

...................................................................................................................................4Specifications

Part II Configuration 8

...................................................................................................................................8Cabling the MaxPro

...................................................................................................................................10Configuring the PC

.......................................................................................................................................................... 10Using a Network Connection

......................................................................................................................................................... 10Direct to the PC

......................................................................................................................................................... 11Through a Network

.......................................................................................................................................................... 11Using a Serial Connection

.......................................................................................................................................................... 12Configuring Windows

......................................................................................................................................................... 12Windows XP

......................................................................................................................................................... 15Windows 2000

......................................................................................................................................................... 18Windows 98

...................................................................................................................................20Configuring the Software

.......................................................................................................................................................... 20Installing Job Server

.......................................................................................................................................................... 31Installing Vision Pro/Vision Pro LT

.......................................................................................................................................................... 40Configuring Vision Pro/Vision Pro LT

...................................................................................................................................46Table setup

.......................................................................................................................................................... 46T-Slot table .......................................................................................................................................................... 48Vice .......................................................................................................................................................... 51Rotary .......................................................................................................................................................... 53Using Water ......................................................................................................................................................... 53Filling the Reservoir

......................................................................................................................................................... 54Adjusting the flow

Part III Operations 58

...................................................................................................................................58Starting the Job Server

...................................................................................................................................60Hand Held Pendant

.......................................................................................................................................................... 60Buttons .......................................................................................................................................................... 68LCD Display

...................................................................................................................................76Operations and Lessons

.......................................................................................................................................................... 76Selecing machine drivers

.......................................................................................................................................................... 79Holding Flat Items with the T-Slot table

.......................................................................................................................................................... 82Lesson 1 - Engraving a Small Name Badge

.......................................................................................................................................................... 88Lesson 2 - Engraving Pens

.......................................................................................................................................................... 95Lesson 3 - Engraing Round objects

.......................................................................................................................................................... 106Lesson 4 - Engraving Luggage tags

.......................................................................................................................................................... 115Lesson 5 - Engraving Rings and Bracelets

.......................................................................................................................................................... 134Advanced Text Options