HOW TO HOLD YOUR HANDPIECE

Normally, you should hold your handpiece like a table knife, not

like a pencil. A few exceptions are hammering and stippling.

Resist the urge to grip your handpiece tightly. Train yourself to

hold the handpiece as softly as you can. When you grip it tightly

or push hard with your hand, you lessen the impact power and

create more work for yourself. So,

relax and let the machine do the

work while you concentrate on the

design you are working on. When

you are doing heavy work, try this:

Partially release your grip on the

handpiece as you add more power

with the foot control. You will be

amazed at how much more power

you have. If you slip with the

graver, you are not operating your

handpiece properly, and probably

pushing too hard with your hand.

Hammering is a special situation.

When hammering you usually hold

the handpiece like a pencil. If you

are hammer setting, be sure to

press the hammer tip down rmly

on the work BEFORE using the

foot control to start hammering.

Also, do NOT operate the hammer

by holding the tip slightly above

the work as with many exible-

shaft hammers. Do NOT allow

the hammer tip to “bounce”

against the work. Use just enough

downward pressure to keep

the hammer from jumping off the work. GRS handpieces have

tremendous power. Use just enough power to do the work ... take

it easy at rst!

HOW TO USE THE FOOT THROTTLE

The GraverSmith foot throttle is operated like an automobile

accelerator and NOT like a exible-shaft foot control. You should

put the tool in position BEFORE depressing the foot control.

Never depress the foot throttle and then try to bring a stroking

handpiece to the work! If you need more power when cutting

deeper, push more on the

foot throttle to increase the

handpiece power. You will soon

learn to coordinate your foot

action with the need for more

power as you work. A beginner

will push the foot control down

a set amount and try to do the

rest by pushing the handpiece

harder, while never changing

foot position. This is incorrect

and not a safe way to use a handpiece. At the start of the cut,

increase power in a smooth fashion. If you need more power,

press more with your foot. As the cut tapers to the end, reduce

the foot pressure gradually as your hand tilts the graver up and

out. With a little practice, this hand/foot coordination will become

as natural as driving a car.

MAINTENANCE

IMPACT HANDPIECE CLEANING

DO NOT USE SOLVENT! The impact handpiece must be kept

clean for proper operation. If operation becomes sluggish, erratic,

or fails, follow these cleaning instructions.

Remove piston and spring from the handpiece. One at a time,

place in a sheet of writing or copier paper. DO NOT USE paper

towel, tissue, or newsprint. Holding it between your ngers (FIG.

5) “buff and polish” off any dirt or residue. Folding the paper, use

the edge to clean between the

piston grooves and the spaces

between the spring.

To clean the handpiece inside,

take the writing or copier paper

and twist it to a point (FIG. 6).

Insert the paper point into the

handpiece and rotate paper

and handpiece against each

other. This will “buff and polish”

the inside clean.

IMPORTANT NOTE: DO NOT

LUBRICATE PISTON, SPRING

OR BORE. Oiling: Occasionally

place a drop of synthetic oil or

light grease on the handpiece chuck

threads / jaws or Quick Change chuck. This will extend useful life,

and improve operation.

THROTTLE

The throttle should require little maintenance. It should be

cleaned periodically. Oiling: Periodically place a drop of oil on

the throttle hinges. When cleaning the oor, place foot throttle on

your bench or chair to prevent damage from debris.

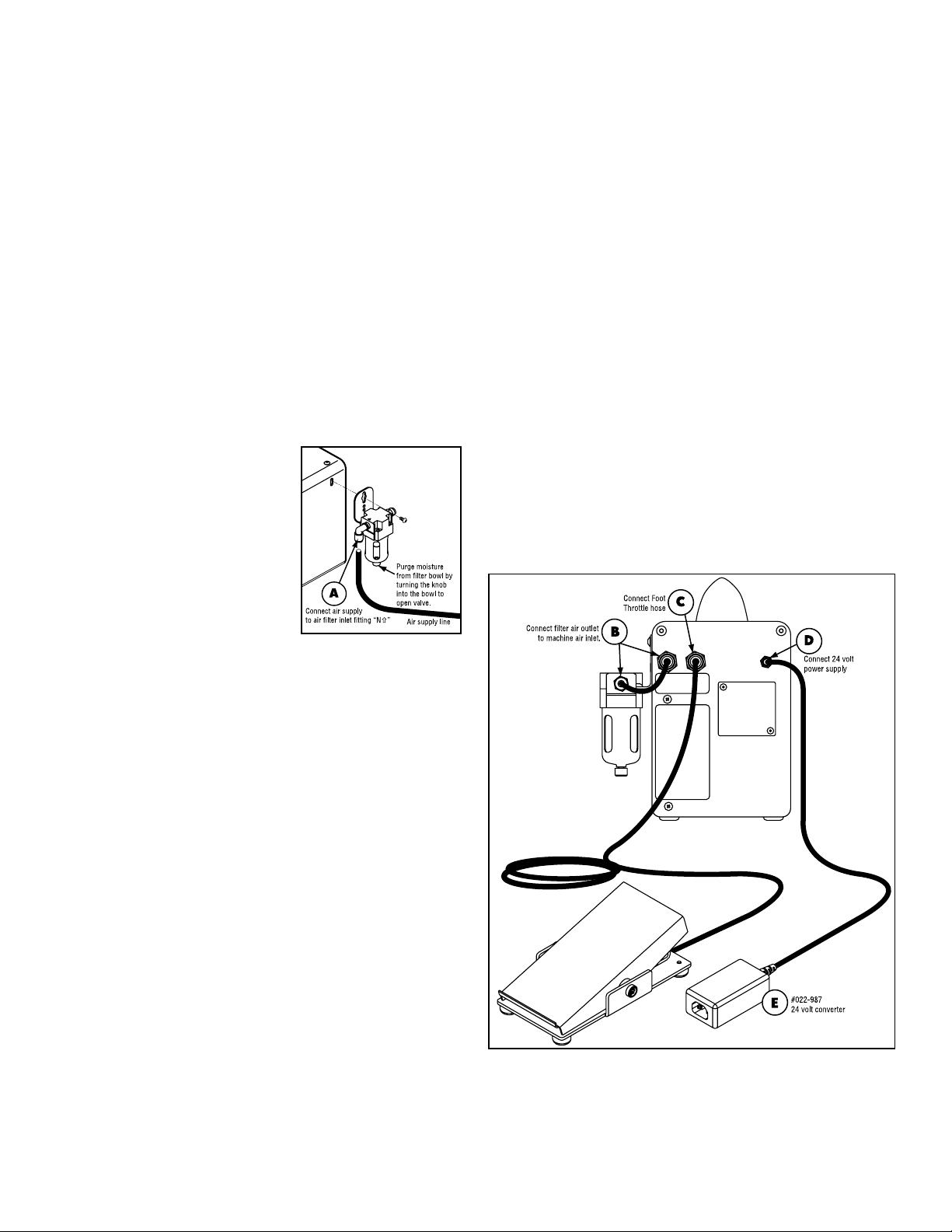

AIR SYSTEM

If large amounts of water and contaminants are in the air supply

to the unit, more frequent attention must be given to the units

lter. The bowl must be drained frequently to prevent water from

entering the rotary valve, hoses, handpiece, etc. In addition, the

lter element must be cleaned and / or replaced frequently. If

moisture is noted in the handpiece or throttle hoses, shut the unit

down immediately and drain the lter bowl, and then follow these

instructions:

1. Disassemble and clean impact handpiece(s) and reassemble.

2. Reduce pressure setting to 10 psi and turn unit ON to purge

moisture from valves, hoses, etc. - with handpiece not

attached.

ROTARY VALVE

The Rotary Valve is lubricated by air passing through it.

Additional lubrication is not required or recommended.

DO NOT RUN ELECTRICAL SYSTEM UNLESS

AIR SYSTEM IS ON.

FIG. 5

FIG. 5