PAGE 1 of 2 LIT-118

Adjusting The Handpiece To Fit You

With the locking ring slightly loose, you are able to turn the handpiece body and knob

independently. Position the Quick Change holder with the graver “point” down. Rotate

the knob until the hose position is comfortable, then tighten the locking ring.

You can also extend the length of the handpiece a little by unscrewing the knob and

body even more. NOTE: By extending the length you may notice a loss of power

depending on the type of work you are doing.

How To Attach A New Hose

Loosen the locking ring. Remove the knob from the handpiece. Remove the hose by

cutting it off close to the knob. With a small punch, push the hose / brass tting back

into the knob body. Remove the brass tting (#004-409) from the hose. Feed the new

air hose through the hole in the knob (Fig. 1). Insert the brass tting into the end of

the new hose, making sure it is fully seated.

If needed, lubricate the tting rst to help it slip into the hose easier. Then apply a

small amount of water or oil around the outside end of the hose next to the brass

tting and pull the hose back (Fig. 2) into the knob until you see the tip of the brass

tting protrude through the side of the knob. This must be an air tight t, so you will

have to pull somewhat hard (a few pounds of pressure, at least).

Create A Flat On The Bottom (If Desired)

If you choose to put a at on the knob, use the handpiece rst to nd out where the

hose “exit” is most comfortable for you. Note warranty information to the right.

Maintenance

Keeping the 901 clean on the inside. Problems will occur if oil or moisture gets

into the handpiece, especially on the piston. If you notice a loss of power or

erratic performance, rst check if the receiver (chuck) is tight in the handpiece

body. Using a cresent wrench or pliers with a graver inserted in the QC Holder,

gently tighten receiver clockwise (Fig. 3) If erratic performance continues, then

disassemble and clean the handpiece. To disassemble the handpiece, use the

crescent wrench or pliers to grip the graver (Fig. 3) and turn it counterclockwise to

loosen the chuck retainer. Continued on page 2.

GRS 901 Handpiece INSTRUCTIONS

For GraverMach & GraverMax SC #004-901

Standard Spring Fine Spring

Normal Operating Range 18-22 psi (1.2-1.5 bar) / 1400 - 3400 spm 12-15 psi (0.8-1.0 bar) / 1600 - 3600 spm

Recommended Initial Setting 19 psi (1.3 bar) / 2700 spm 13 psi (0.9 bar) / 3000 spm

PSI: Pounds per Square Inch • Bar: Unit of Measurement • SPM: Strokes Per Minute

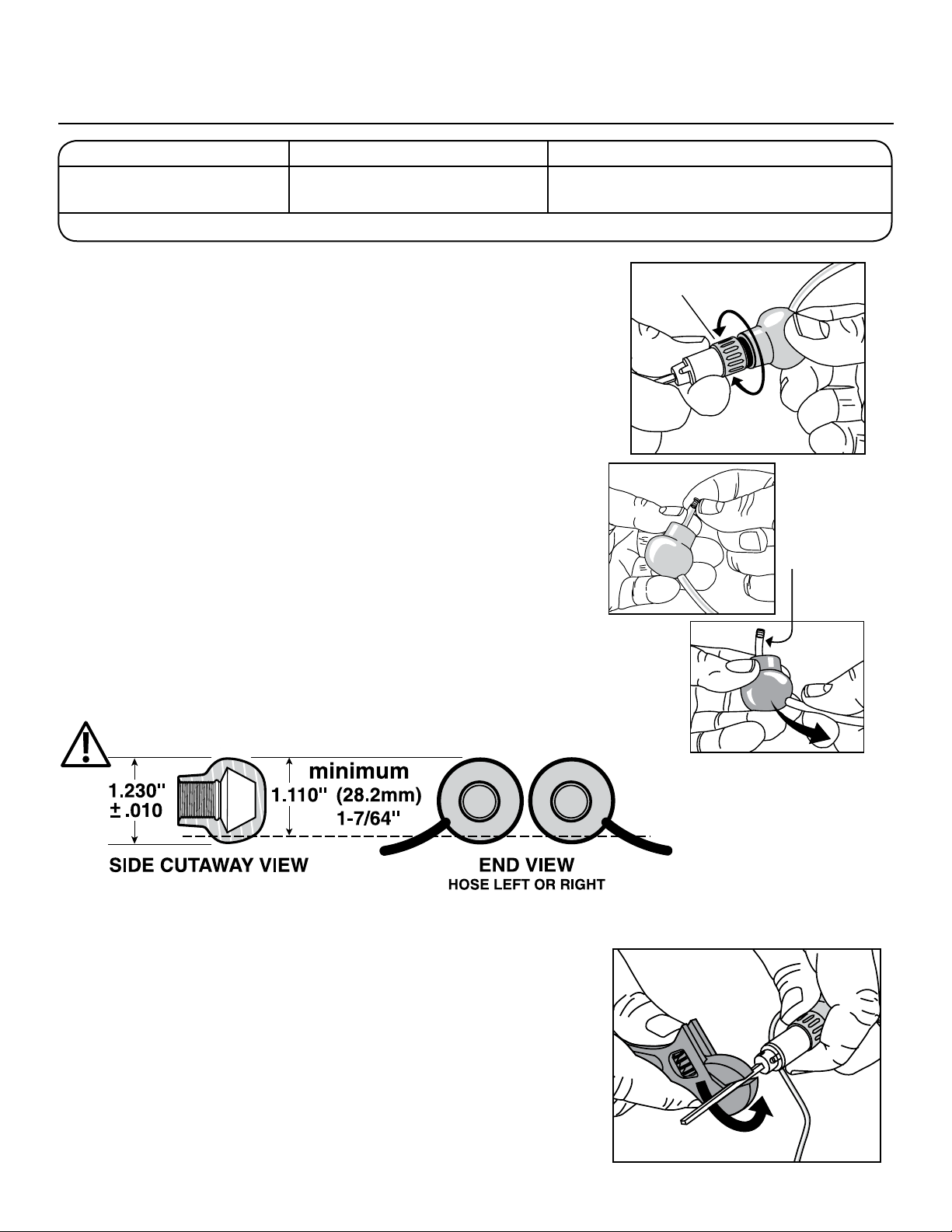

LOCKING RING

Loosen first

Fig. 1

Lubricate end slightly

with water or a small

amount of oil.

Fig. 2

IMPORTANT

Too much material removal will

result in damaged* knob (PART

#004-404).

*Any damage to knob from

creating a at is NOT covered

by warranty.

*METAL REMOVAL PAST MINIMUM DIMENSION WILL DAMAGE KNOB

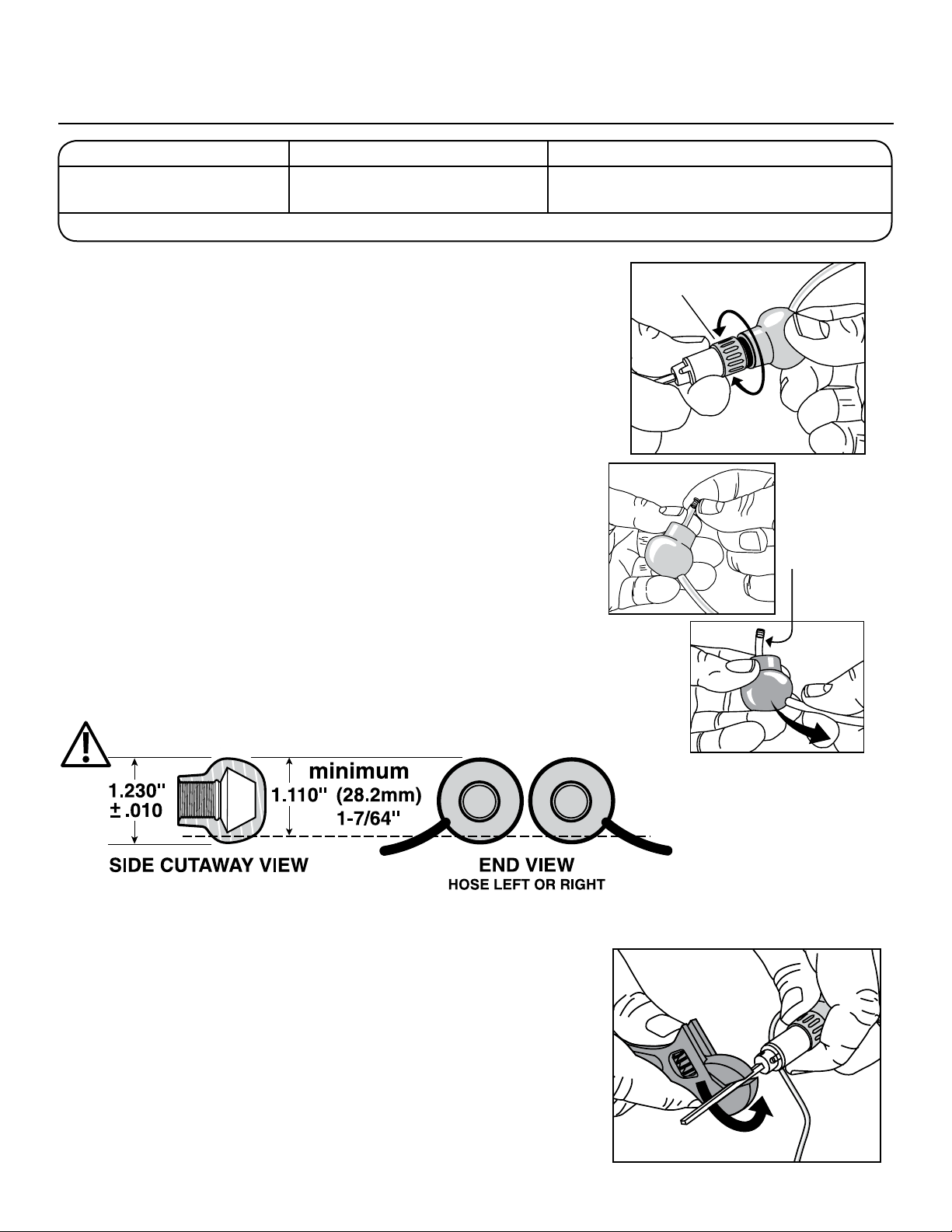

LOOSEN

TURN COUNTERCLOCKWISE

TIGHTEN

TURN CLOCKWISE

Fig. 3