General notes Our systems have to be installed by an

approved sanitary or heating company.

Prior to installation, check the compo-

nents for shipping damage.

The devices must be protected against

frost and must not be installed near heat

sources which radiate a lot of heat.

Attention: Do not clean the filter with

cleaning agents that contain alcohol or

solvents!

In case of drinking water that contains a

lot of coarse dirt, a coarse filter must be

installed upstream.

1 Application The FS-B filters are designed for the

filtration of drinking water. The filters are

not suited for circulation water that has

been treated with chemicals. Further-

more, it is neither suited for oils, greas-

es, solvents, soaps and other lubricating

media nor for the separation of water-

soluble materials. The filters may be

used in the pressure and negative pres-

sure range.

2 Technical specifications

Fine filter FS-B

Connection diameter 1“ 1¼“ 1½“ 2“

Nominal connection diameter [DN] 25 32 40 50

Nominal flow at

p 0.2(0.5) bar [m³/h] 3.7(6,0) 4.0(6,2) 11.1(19,9) 13.9(23,3)

Filter fineness [µm] 80

Diameter of upper/ lower

outlet [µm] 140/80

Nominal pressure PN 16

Total height [mm] 265 508

Replacement height for

filter element [mm] 150 390

Length with/without screw

connections [mm] 182/100 191/100 283/160 277/160

Empty weight [kg] 1.2 1.4 3.7 4.4

DVGW registration mark NW-9301BT0200

Max. water / ambient

temperature [°C] 30/40

Order no. 101 170 101 175 101 180 101 185

3 Installation

requirements Please observe local installation guidelines

and general regulations as well as tech-

nical specifications.

The installation site must be frost-proof

and must ensure the protection of the

filter against chemicals, dyes, solvents,

vapours and direct sunlight.

Observe flow direction (indicated on

the housing)! Install voltage-free. The

installation site must be frost-proof.

The filter should be installed in equally

dimensioned pipes according to its

nominal diameter.

4 Scope of

delivery

Filter with protective cover and built-

in maintenance indicator.

Screw connections with seals made

of LD-PE.

Filter element 80 µm

Operation manual

5 Installation

As per DIN EN 806-2 and DIN 1988-200

the FS-B filter has to be installed in the

cold water pipe downstream of the water

meter and upstream of the distribution

pipes respectively upstream of the de-

vices to be protected. Install shut-off

valves upstream and downstream of the

filter (refer to fig. 1). The filter is suited

for horizontal installation only.

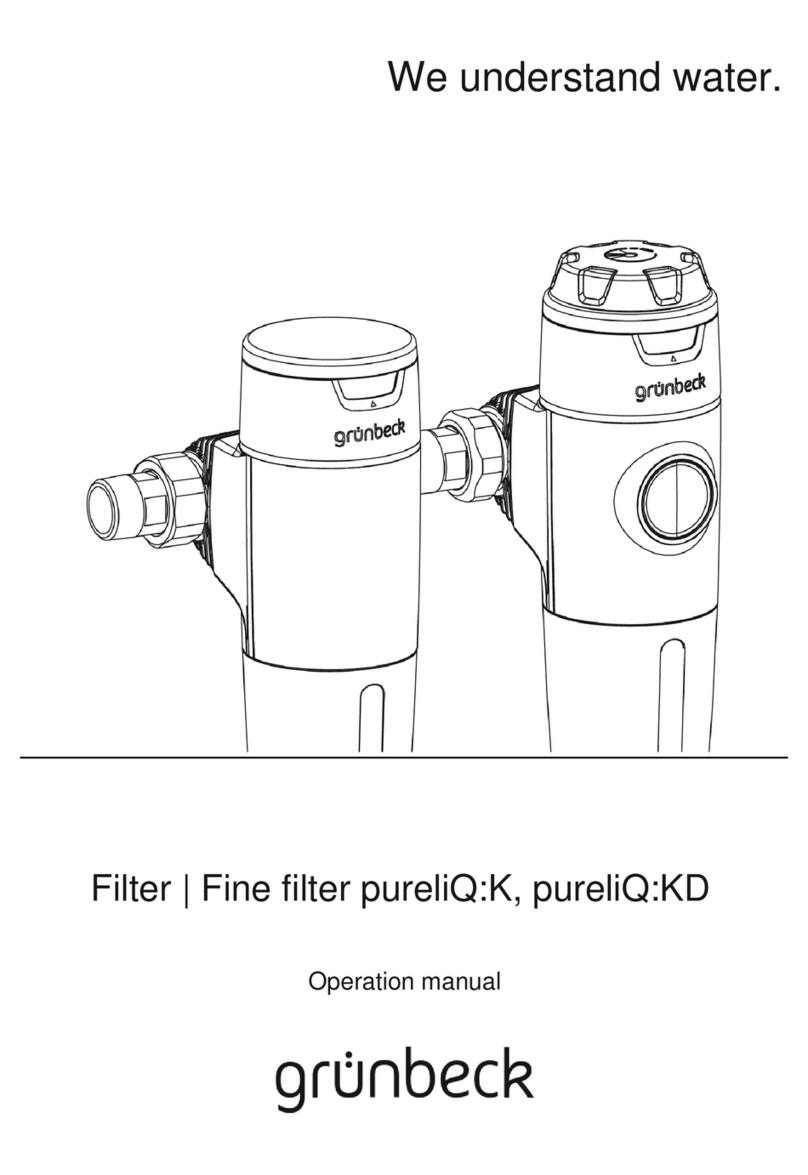

Fig. 1: Installation drawing FS-B front view

1

Union nut

2

Insert

3

Flat seal

Fig. 2: View FS-B

6 Start-up After completion of the installation, put

the filter into operation by opening the

shut-off valves. Then de-aerate the

piping via the nearest screw connection.

Leakage test

A leakage test must be performed on the

filter directly after installation and after

each time maintenance work was per-

formed. In order to check the filter for

tightness, the highest pressure admissi-

ble must be applied.

7 Inspection /

Maintenance According to the DIN Standard EN 806-

5, the operator must inspect the filters

every two months (functional inspection).

During the inspection, the filter element

must be checked for contamination and

be replaced, if necessary (contamination

and/or increased differential pressure).

Check for tightness.

Furthermore, maintenance has to be

performed by the operator or the installa-

tion company every six months.

Warning! According to DIN EN 806-5

the filter element must be replaced for

hygienic reasons every 6 months. Fur-

thermore, we recommend replacing the

seal of the protective cylinder every 2

years using a set of seals.

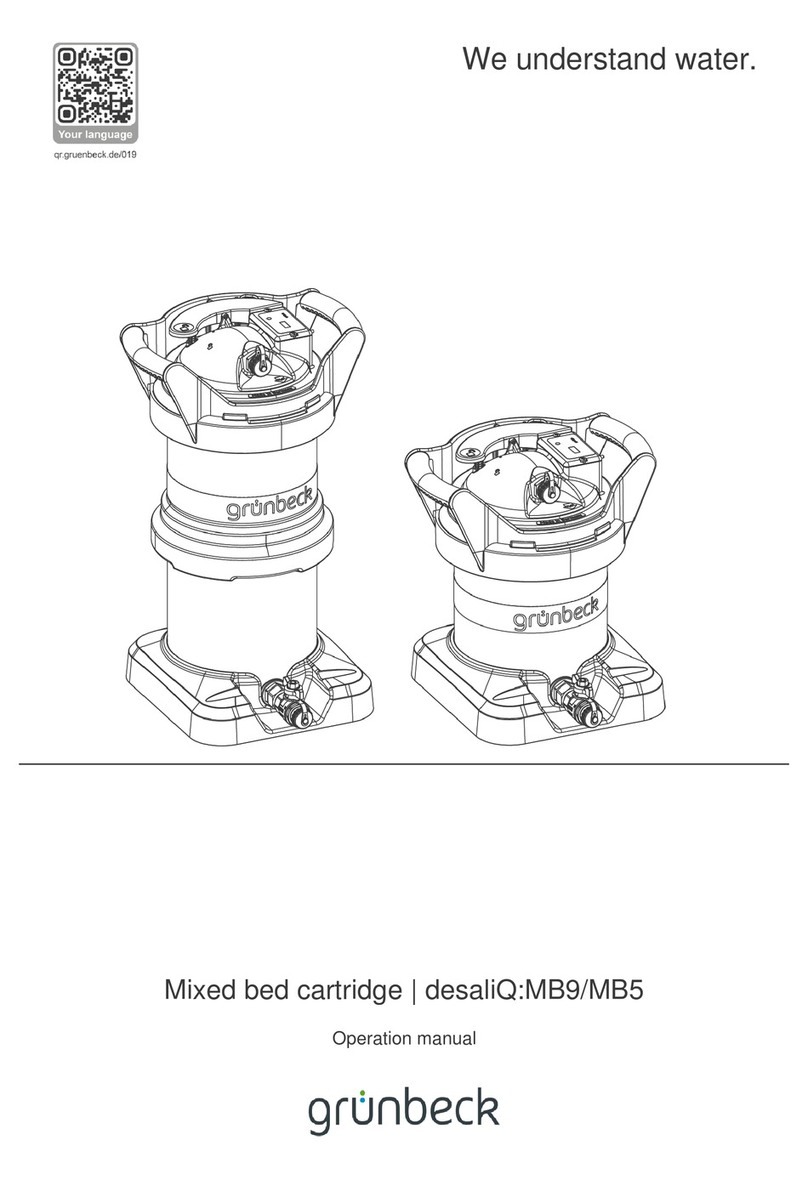

Replacement of

filter element

Fig.3: Replacement of

filter element

How to proceed

Place a bucket beneath the filter.

Close the shut-off valves.

Depressurize the pipe.

Manually unscrew the filter cylinder.

Remove the dirty filter element from

the supporting fabric and replace by

new filter element. For hygienic rea-

sons, do not touch the new filter ele-

ment with bare hands.

Hygienic filter replacement:

Open the foil and push the filter ele-

ment including the foil over the support-

ing fabric, pull off the foil without touch-

ing the filter element. (see fig. 3)

Check that the sealing surfaces as

well as the O-ring are clean and

manually screw on the filter cylinder

to the stop.

Start up as described in point 6.

Edited by: KONS-fger-mrie G:\BA-101196-INTER_FS-B.DOC